|

US$14.00-40.00

|

1 kg

(MOQ)

|

Basic Info.

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23

Material

Ta6V Titanium Alloy

Surface Treatment

Polishing

Standard

ASTM, ISO, AMS, JIS, DIN

Condition

Annealed (M), Cold Rolled(Y), Hot Rolled(R)

Transport Package

Wooden Case

Specification

1.0~101.6mm

Production Capacity

200tons/Year

Product Description

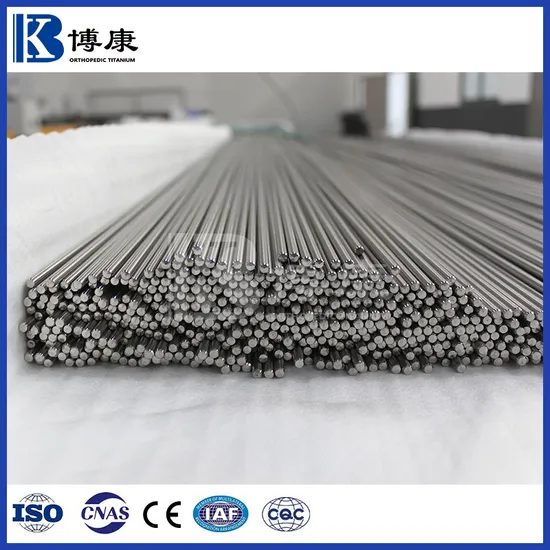

Product Description High-Quality Titanium Rods - Pure & Alloy Options Available

Bokang Titanium specializes in pure titanium rods (Gr1, Gr2, Gr3, Gr4) and titanium alloy rods (Gr5, Gr9, Gr23, etc.), offering premium-grade materials for medical, aerospace, and industrial applications.

Medical Titanium Rods - Ideal for orthopedic implants, dental applications, and medical devices.

Aerospace Titanium Rods - Used in fasteners, profiles, and high-strength forgings.

Industrial Titanium Rods - Engineered for high-performance industrial needs.

With a complete in-house production process, including melting and customization, we ensure precision and reliability. Bokang is ISO 13485:2016, ISO 9001, and ISO/IEC 17025:2017 certified, and our titanium rods meet ASTM, ISO, AMS, ASM, JIS, DIN standards.

Contact us today for a quote or to discuss your specific requirements!

Titanium Bar Specifications

Grade

| Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6Al-4V),Gr9(Ti-3Al-2.5V),Gr23(Ti-6Al-4V ELI), etc

|

Standard

| ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4965;AMS4967;ASTM B348; ASTM B863

|

Diameter(mm)

| 1.0~101.6mm

|

Length(mm)

| 500-4000

|

Tolerance

| h6,h7,h8,h9

|

Shape

| Round

|

Condition

| Annealed (M), Cold rolled(Y), Hot rolled(R)

|

Surface

| Bright Surface

|

High-quality titanium bar/rods with various diameters, tolerances and performances can be customized according to requirements

Titanium Round Bar - Key Features

Superior Surface Finish - Smooth and precise for optimal application.

Excellent Roundness - Ensures uniform shape and consistency.

Tight Tolerances - High precision for demanding industries.

High Dimensional Stability - Reliable performance under various conditions.

Consistent Composition - Uniform material properties for enhanced durability.

Fine Grain Structure - Strength and toughness in every bar.

Exceptional Performance - Engineered for high-strength applications.

Extended Fatigue Life - Designed to withstand long-term stress and usage.

Precision, Performance, and Reliability - Choose Bokang Titanium!

Titanium Round Bar Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Machining→Forging Billet→UT testing→Rolling Billet→Online Straightening→Centerless Lathe→UT testing→Rolling→Metallographic Inspection→Wire Drawing→Precision Straightening→Heat Treatment→Mechanical test→Microstructure test→Centerless Grinder→Eddy Current Test→Polishing→Visual and dimension inspection→Product Marking→Packaging→Delivery

Applications of Titanium Round Bar:

Titanium rods are extensively used in the medical industry, providing exceptional strength, biocompatibility, and corrosion resistance. Key applications include: Orthopedic Implants - Hip and knee replacements, bone fixation devices.

Dental Implants - Durable and biocompatible solutions for long-term use.

Ultrasonic Scalpels - High-precision surgical tools for minimally invasive procedures.

Surgical Staplers - Reliable performance in medical suturing applications.

Other Surgical Instruments - Ensuring precision and longevity in medical procedures.

Engineered for Medical Excellence - Trusted by Professionals Worldwide!

Chemical Composition Chemical Composition

ASTM F136 Ti-6Al-4V ELI Chemical Requirements:

Element

| Composition,% (mass/mass)

|

Nitrogen (Maximum)

| 0.05

|

Carbon (Maximum)

| 0.08

|

Hydrogen (Maximum)

| 0.012

|

Iron (Maximum)

| 0.25

|

Oxygen (Maximum)

| 0.13

|

Aluminum

| 5.5-6.50

|

Vanadium

| 3.5-4.5

|

Titanium

| balance

|

Mechanical Properties Mechanical Properties

ASTM F136 Ti-6Al-4V ELI Annealed Mechanical Properties:

Diameter

in(mm)

| Tensile strength

Min, psi (MPa)

| Yield strength(0.2%,offset)

Min, psi (MPa)

| Elongation in 4D or 4W Min (%)

| Reduction of Area Min (%)

|

L

-

| LT

-

| ST

-

| L

-

| LT

-

| ST

-

|

<0.187

(<4.75mm)

| 125000(860)

| 115000(795)

| 10

| ...

| ...

| ...

| ...

| ...

|

0.187~1.75

(4.75~44.45mm)

| 125000(860)

| 115000(795)

| 10

| ...

| ...

| 25

| ...

| ...

|

>1.75~2.50

(44.45~63.50mm)

| 120000(825)

| 110000(760)

| 8

| ...

| ...

| 20

| ...

| ...

|

>2.50~4.00

(63.50~101.60mm)

| 120000(825)

| 110000(760)

| 8

| 8

| 8

| 15

| 15

| 15

|

Tolerance (mm)

ASTM F136 Ti-6Al-4V ELI Tolerance:

Diameter(mm)

| Thickness tolerance(mm)

|

>3~6

| 0,-0.012

|

>6~10

| 0,-0.015

|

>10~14

| 0,-0.018

|

>14~18

|

>18~24

| 0,-0.021

|

>24~30

|

>30~40

| 0,-0.025

|

>40~50

|

>50~65

| 0,-0.030

|

>65~80

|

>80~100

| 0,-0.035

|

Product Category

| | |

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| | |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

Certifications

About Bokang

Our Advantages

FAQ Q: Are you a manufacturer or a trading company?

A: We are a direct manufacturer with 18+ years of experience in titanium production. Q: Do you provide free samples?

A: Yes, we offer free samples, but customers need to cover the shipping cost.

Q: What is the minimum order quantity (MOQ)?

A: 1 kg. We maintain a 20-ton monthly production capacity for titanium rods and wires, ensuring sufficient stock for standard medical and aerospace materials.

Q: What titanium products do you offer?

A: Our product range includes pure titanium, titanium alloys, titanium rods, wires, discs, sheets, plates, nitinol alloys, and more.

Q: What are your payment terms?

A: Payment terms vary based on the transaction type (FOB, CIF, CNF, etc.).

For mass production, we require 30% deposit before production and 70% balance against shipping documents. We accept T/T and L/C payments.

Q: What industries do your products serve?

A: Our titanium and nitinol alloys are widely used in medical, aerospace, and industrial applications.

Q: How can I get a price quote?

A: To provide an accurate quote, please provide the following details:

1 Product Name

2 Standard

3 Material Grade (Chemical Composition)

4 Dimensions

5 Quantity

Q: Do you offer custom manufacturing?

A: Yes! We provide customized titanium products based on customer drawings or samples.

Q: How do you ensure product quality?

A: We implement strict quality control at every stage of production, using advanced testing equipment to meet customer and international standards.

Q: What are your shipping options?

A: We ship via sea or air, depending on customer requirements.

Contact us today for more details or a custom quote!

>>

Manufacturer Wholesale Disposable Infusion Set Cheap Price Medical Disposable IV Infusion Set

>>

8oz, 12oz, 16oz, 24oz, 32oz Disposable Plastic Soup Bowl Food Deli Container with Lids Leak-Proof

>>

Std-120 200L Extrusion Type Sino-Tech Drum Mold Blow Molding Machine with CE and ISO

>>

Packaging Food Plastic Container Injection Mould

>>

1.9m Working Width Tiller Middle Duty Disc Harrow

>>

HRC-115 Principle of Differential Scanning Calorimetry

>>

Laminated Multiple Layer Plastic Aseptic Empty Aluminum Foil Spout Bag in Box with Butterfly Tap

>>

High Speed Plate Drilling Machine CNC Tapping Machine

>>

Two-Dimensional Motion Mixer for Electrostatic Precipitator

>>

Factory Direct Supply Peche Fishing Rods Carbon Fiber Olta Pesca Wholesale Fishing Spin Casting Rod

>>

Portable WiFi 7inch Touch Screen Ahd/CVBS CCTV Test Monitor for Pipe Sewer

>>

Qk1332 High Quality Automatic Metal Turning CNC Pipe Cutting Machinery

>>

Trumpf Original Beveler TruTool TKF 700 beveling machine

>>

Full Automatic Total Sulfur Tester (Ultraviolet Fluorescence)

>>

Automatic Chicken Poultry Farm Equipment for Sale

>>

Granule Automatic Weighing Premade Zipper Bag Pet Food Cat Litter Filling Stand Up Pouch Packing Machine

>>

One person can operate 5 automatic drum cooking machines

>>

Silicon carbide wear-resistant elbow

>>

6X7+FC Diameter 23mm Steel Wire Rope Ungalvanized and Galvanized for Belt Conveyer, Ropeway Drawing and Winch

>>

Waterproof Exterior Fiberglass Doors with Door Frame That Look Like Wood