Product Details

Product Description

Product Description

Eqobrush demostration

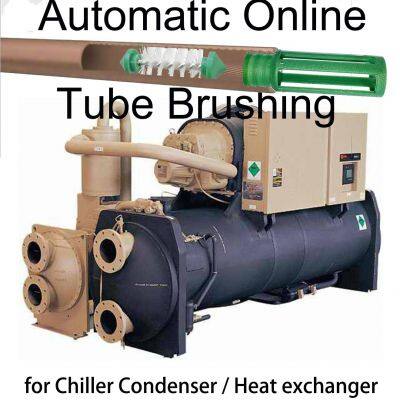

Brush type Automatic Tube Cleaning System(ATCS) Designed for Chiller Condensers and Shell-and-Tube Heat Exchangers

EQOBRUSH is an automatic tube brush cleaning system specifically designed for chiller condensers and shell-and-tube heat exchangers. Utilizing intelligent cleaning technology, it ensures that equipment maintains optimal heat dissipation during operation, minimizing the negative impacts of fouling. Whether in industrial manufacturing, commercial buildings, data centers, or hospitals, EQOBRUSH significantly enhances equipment operating efficiency while reducing energy consumption and maintenance costs.

Core Advantages of EQOBRUSH1. Efficient Cleaning Without Downtime

The EQOBRUSH system automatically cleans all tubes during equipment operation, eliminating the need for shutdowns. Through multiple daily cleaning cycles, the system ensures that tubes remain clean, preventing efficiency losses caused by fouling. Compared to traditional manual cleaning methods, EQOBRUSH not only saves time but also reduces production losses associated with downtime.

2. Significant Energy Savings and Reduced Consumption

Fouling can lead to a substantial increase in energy consumption for chillers. EQOBRUSH ensures that equipment maintains optimal heat dissipation efficiency through automatic cleaning, reducing energy consumption by over 10% compared to periodic manual cleaning. This translates to significant annual savings on electricity costs for users.

3. Environmental Sustainability

EQOBRUSH employs mechanical cleaning, reducing reliance on chemical cleaning agents. This not only minimizes environmental pollution but also lowers the costs associated with purchasing and disposing of chemicals. Additionally, the system reduces water consumption by increasing the concentration cycles of cooling water, aligning with modern corporate sustainability goals.

4. Intelligent Control and User-Friendly Operation

EQOBRUSH is equipped with a programmable touchscreen control panel, allowing users to easily set up and monitor cleaning cycles. The system also supports remote performance monitoring, enabling users to track equipment efficiency and operational status in real-time via IoT technology, ensuring optimal performance at all times.

5. Extended Equipment Lifespan and Reduced Maintenance Costs

Fouling and deposits not only impair equipment efficiency but also lead to pipe corrosion and leaks, shortening equipment lifespan. EQOBRUSH mitigates these issues through continuous cleaning, significantly extending equipment life and reducing the frequency of replacements and repairs.

6. Quick Installation and Easy Maintenance

The EQOBRUSH system can be installed in just a few days, with detailed installation manuals provided. The cleaning brushes and capture baskets are easy to disassemble and replace, with a service life of 3-5 years, ensuring low maintenance costs. Professional personnel handle installation and commissioning, enabling users to quickly put the system into operation.

Wide Application Scenarios for EQOBRUSH

EQOBRUSH is suitable for a variety of industries and equipment types, including:

Industrial Manufacturing: Maintains efficient operation of cooling systems in production equipment, reducing downtime.

Commercial Buildings: Enhances the energy efficiency of central air conditioning systems, lowering operational costs.

Data Centers: Ensures efficient operation of server cooling systems, preventing equipment failures due to overheating.

Hospitals: Maintains stable operation of medical equipment, ensuring a comfortable and safe medical environment.

High Return on Investment and Rapid Cost Recovery

EQOBRUSH not only significantly reduces energy consumption and maintenance costs but also offers a high return on investment (ROI). Based on actual usage, users typically recover their investment within two years through energy savings and reduced maintenance expenses. For businesses focused on long-term operations, EQOBRUSH is a cost-effective choice.

EQOBRUSH: Enhancing Equipment Efficiency, Reducing Costs, and Promoting Sustainability!

>>

bathroom floor ceramic tile bathroom net tile porcelain porcelanato glazed kitchen room

>>

Custom Food Take Away Food Grade Brown Kraft Paper Lunch Box Making Machine

>>

Stardrawing Stainless Steel Heavy Duty Leveling Feet Caster Wheel Leveling Caster

>>

Best Price /72V4a 72V32ah /Lead Acid /Lithium Battery Charger / E-Scooter Charger

>>

12/24 Cores MPO MTP Sm Om3 Om4 Om5 Fiber Optic MPO Fiber Cable

>>

DVB-T Antenna with F Male Connector

>>

24tubes Aluminum Alloy High Pressure Heat Pipe Solar Collector

>>

Colorful/Various Patterns/Waterproof/Radiation Resistance/Aging Resistance 3D Wall Sticker

>>

2019Hot sale newspaper pencil making machine

>>

High Quality Unbreakable Waterproof Engineering Vehicles Polycarbonate Glass

>>

Density Gradient Column

>>

Inclined Lift Driven in Rack and Pinion Hoist Lift

>>

New Type Fried Instant Noodles Making Machine/Fried Noodle Making Processing Line/Instant Noodle Making Equipment Machine/ Indomie Noodles Making Machine

>>

F770 Aircraft Toys Children′ S Small Crash Resistant Remote Control Helicopter

>>

New Unique Gourd shape Rattan rattle Kid's Toys Hanging Play Gym hand bell Vietnam Wholesale Supplier

>>

ASTM B441 Beryllium Copper Tube C17500

>>

Drill press in machinery Z5040C hydraulic drilling machine pdf

>>

Vertical Manual Milling Machine Reliable Conventional Milling Machine for Metal

>>

High Performance Double Column Gantry Milling Machine/CNC Horizontal Gantry Machining Center

>>

WELDON OEM Ambulance Aluminium Interior Cabinet And Parts, Custom Ambulance Cabinets, Metal Fabricatoin