|

US$38,000.00-42,500.00

|

1 Piece

(MOQ)

|

Basic Info.

Controlling Mode

Artificial

Automatic Grade

Automatic

Cylindrical Grinder Type

Surface Grinding Machine

Certification

CE, ISO 9001

Working Surface of Table

600X2000mm

Automatic Cross Feed of Saddle

0.5~12 mm

Power Head Increment

230 mm/Min

Spindle Bearing

NSK Brand P4 Grade

Main Electrical Components

Siemens Brand

Cross Screw

P5 Grade Precision Ball Screw

Main Hydraulic Components

Taiwan Brand

Transport Package

Non-Fumigation Plywood Case

Specification

5800x2260x2250mm, 9700kg

Production Capacity

80 Sets/Month

Product Description

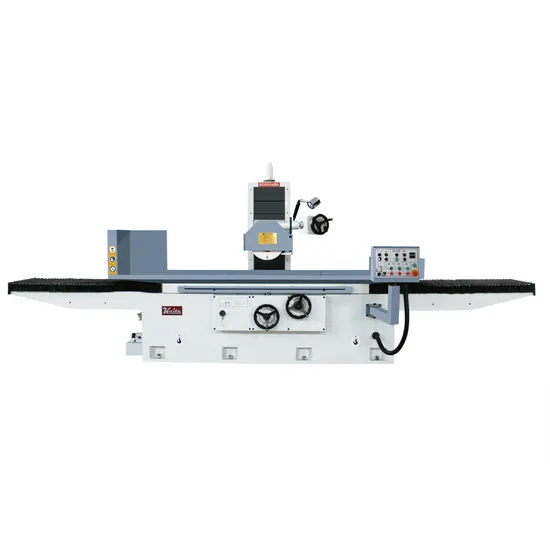

1. Picture

AHR: 2-axis automatic feed

hydraulic automatic longitudinal feed

electronic automatic cross feed

electronic rapid up and down feed

AHD: 3-axis automatic feed

hydraulic automatic longitudinal feed

electronic automatic cross feed

incremental auto down feed (use hydraulic system and gear box)

2. Parameters

| Parameters | Unit | KGS620AHR | KGS620AHD |

| Working Surface of Table | mm | 600×2000

(24"×80") | 600×2000

(24"×80") |

| Max.Table Travel | mm | 2230 | 2230 |

| Max.Cross Travel | mm | 650 | 650 |

Distance Between Table

Surface and Spindle Center | mm | 600 | 600 |

| Max.Table Load | kgs | 1500 | 1500 |

| T-Solt(Number×Width) | mm | 3×16 | 3×16 |

| Table Speed | m/min | 7~25 | 7~25 |

| Crossfeed Handwheel | 1gard | mm | 0.02 | 0.02 |

| 1 rev | 5 | 5 |

| Automatic Crossfeed of Saddle | mm | 0.5~12 | 0.5~12 |

| Power Cross Feed | 50HZ | mm/min | 1250 | 1250 |

| 60HZ | 1500 | 1500 |

| Grinding Wheel Dimensions | mm | 355×50×127 | 355×50×127 |

| Spindle Speed | 50HZ | rpm | 1450 | 1450 |

| 60HZ | 1740 | 1740 |

| Vertical Handwheel | 1gard | mm | 0.002 | 0.002 |

| 1 rev | 0.5 | 0.5 |

| Automatic Down Feed Rate | mm | - | 0.005~0.04 |

| Power Head Increment | mm/min | 230 | 230 |

| Spindle Motor | kw | 7.5 | 7.5 |

| Vertical Motor | w | 370 | 370 |

| Hydraulic Motor | kw | 5.5 | 5.5 |

| Dust Collection Motor | w | 550 | 550 |

| Coolant Motor | w | 90 | 90 |

| Crossfeed Motor | w | 370 | 370 |

| Floor Space | mm | 6200×2700 | 6200×2700 |

| Packing Dimensions | mm | 5800×2260×2250 | 5800×2260×2250 |

| Net Weight | kgs | 8500 | 8500 |

| Gross Weight | kgs | 9700 | 9700 |

3. Main Configuration of Grinding Machine

1. Spindle motor: ABB brand.

2. Spindle bearing: NSK brand P4 grade precision ball bearing which from Japan.

3. Cross screw: P5 grade precision ball screw.

4. Main electrical components: SIEMENS brand.

5. Main hydraulic components: brand from TAIWAN.

4. Standard Accessories

| 1 | Grinding wheel | 2 | Wheel flange |

| 3 | Wheel balancing base | 4 | Wheel balancing arbor |

| 5 | Extractor | 6 | Diamond dresser |

| 7 | Leveling pad | 8 | Anchor bolt |

| 9 | Tool box with tools | 10 | Electric magnetic chuck |

| 11 | Cooling system | 12 | Working light |

5. Optional Accessories

| Serial No. | Name of Article |

| 1 | rear splash guard |

| 2 | DRO (digital read out) |

| 3 | overhead parallel dresser |

| 4 | hydraulic tank oil cooling |

| 5 | cooling & suction device |

| 6 | magnetic separator |

| 7 | cooling magnetic paper filter |

| Note | 6 and 7, select one just OK. |

6. Feature

1. Well designed cast iron structure provides excellent dampening

2. Flange mount spindle cartridge for superior side grinding rigidity

3. Grinding spindle features low-maintenance preloaded high precision angular ball

bearings(NSK P4 grade)

4. "V" and flat type guide way which precision hand scrapped turcite saddle ways for smooth and long lasting performance

5. Table guideways are hardened, ground and counter-laminated with PTFE(TEFLON) to ensure high wear-resistance

6. Centralized automatic lubrication system ,supplies oil to guide-ways and lead-screws as the machine operates. This system ensures all the critical components are lubricated with the right amount of oil at all times

7. Separate hydraulic tank prevents heat and vibrations from being transferred to the machine

8. Electric components and functional modules are well arranged and packed in the electric cabinet, making maintenance and trouble-shooting easily accessible

9. Magnetic force can be adjusted

10. Safety 24V control circuit power

7. Company & Factory

Nantong Kaite Machine Tool Co., Ltd.

A Sino-US joint venture machine tool company with KENT INDUSTRIAL (USA) INC.

KAITE specializes in manufacturing precision surface grinding and milling machine since 1999.

KAITE supply the USA quality machines and with China price.

KAITE is located in Nantong city, Jiangsu Province where near Shanghai city and welcome to visit us!

8. Delivery Picture

>>

High Quality Stainless Steel 1000liters Two Vessel Small Micro Pub Beer Brewery Equipment Beer Manufacturing Beer Factory Machinery

>>

Sand pumping pump

>>

High Quality Plastic PVC Rain Gutter Downspout for Villa House

>>

1-4 ton fertilizer mill fertilizer pellet machine fertilizer granulator

>>

High Quality and High-Speed Automatic Cardboard Box Printing Slotting Die Cutting Machine with Stacking Machine

>>

Liuzhou wuling LJ373QE petrol engine auto car parts

>>

Artificial Snow Maker Remote Control Moving Head Machine Wedding Show Stage Lighting Equipment

>>

Prime Focus 450cm Rx Antenna Parabolic Satellite Dish Antenna

>>

Non Woven Hard Cotton/Felt Thermal Bonding Production Line Wadding Materials for Sell

>>

T3 Series Residential Water Meter Sandwich Insertion Ultrasonic Water Meter Ultrasonic Bulk Water Meter

>>

Compatible TN512 Color Toner Cartridge for Konica Minolta Bizhub C454 C554

>>

HC-G034 Clinic digital audiometer with headphone

>>

Corrugated carton assembler partition machine

>>

Small Best Quality and High Efficiency Cow Milking Machines for Cows for Sale

>>

Sy-I081VI Six Function Bioplar Electrosurgical Generator Cautery Machine

>>

Mini Pleat Medium Filter Plastic Frame V Cell Air Filter

>>

cUL Certificate Electric PVC Copper Wire Nmd90 14/2 12/2 14/3 12/3 Indoor Non-Metallic Solid Conductor with Ground Electrical Wire 300V Canada

>>

Bedroom bathroom room Hotel Kitchen UPVC door design

>>

Car Electric ECO power liftgate Factory price wholesale tailgate modified Intelligence anti pinch for tesla model 3

>>

Middle CNC Lathe, Metal turning machine, industrial machine, metal working cnc