|

US$50,000.00-600,000.00

|

1 Set

(MOQ)

|

Basic Info.

Model NO.

500type~6000type

Material Processed

Plastic Flakes

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Machine

PP PE Bottle Washing Line

Capacity

500kg/H-6500kg/H

Solution

Clean Pet Flakes

Material

Carbon Steel or SS304

Motor

Siemens or Other Brand

Since 1992

Can Be Customerized

Delivery Time

Within 45days

Electrical Panel

Chnt or Other Famous Brand

Transport Package

PE Film Strength

Production Capacity

30sets Per Month

Product Description

Product Overview

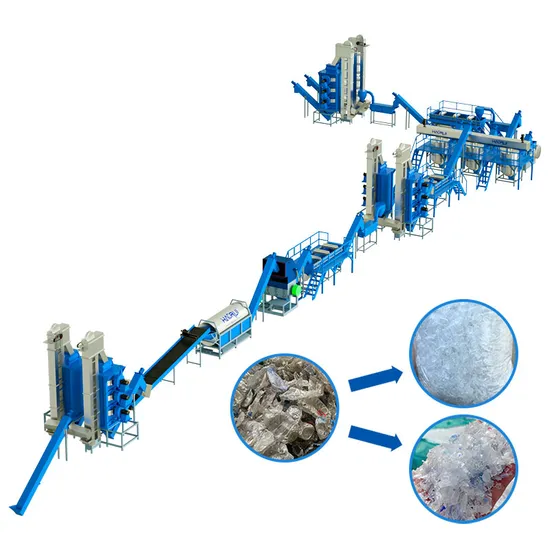

Plastic Recycling Plant/Plastic recycling machine/PP PE Washing Line

usage:Dirty PET bottle into clean and dry PET flakes

Application: PET bottles PP PE

The whole line comes out as clean and dry flakes

There are different offers according to different needs

| type | capacity | power | machine size | weight |

| 500 | 800kg/h | 80kw~150kw | 25m*3m*4m | 20t |

| 1000 | 1500kg/h | 100kw~200kw | 30m*3m*4m | 20t |

| 2000 | 2500kg/h | 200kw~250kw | 60m*5m*5m | 30t |

| 3000 | 3500kg/h | 300kw~350kw | 80m*6m*5m | 40t |

| 5000 | 5500kg/h | 500kw~600kw | 100m*8m*5m | 50t |

| 6000 | 6500kg/h | 600kw~800kw | 120m*8m*5m | 70t |

Details Images

Enough thickness to be stronger

Professional workers carry out processing

Carry out fine production

The special design is to wash more cleanly

Professional workers carry out processing

HAORUI can also produce the PE PE HDPE LDPE washing line and pelletizing machine, crush ,wash and dry the dirty

Other Products

PP pelletizing machine

PP PE HDPE LDPE plastics into clean and dry flakes, then make pellets.

All the production process is completed independently by our factory

Packaging&Shipping

Ensure fast transportation without damage

our advantages

Company ProfileBaoding Haorui Machinery Manufacturing Co.,ltd was established in 1992,is a professional manufacturer and exporter that is concerned with the design,development and production of PET bottle crushing and washing machine, PP PE HDPE LDPE plastic crushing and washing machine, pelletizing machine .There are over 100 technicians in our workshops which covers 20000 square meters. Over 28 years of plastic recycling machines production experience ,enable us to be TOP3 plastic recycling machine factory in China. Our own R&D team make our machine design unique, OEM and ODM service are also welcome. Our main products include bale opener, label remover, plastic crusher, floating tank, screw feeder, high-speed friction washer , hot / cold washer, dewatering machine, pipe dryer and so on.We insist on the principle of "quality is first" and inspect the machine after producing " which make our market more popular in Domestic and over 40 sets of PET bottle washing line(four 6000kg/h capacity in Nigeria ,Ghana etc), PP PE HDPE LDPE washing line ,pelletizing machine were installed in Middle East,Africa,South America,South East, South Asia and so on

Factory

successful case

FAQ

Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hoursQ: How about the rate for removing the labels by Label remover?A: Compressed bottle: more than 96% Un-compressed bottle: more than 98%Q:What's the temperature of steam washer ?A: Usually 80-90ºC ( If the temperature is over 100ºC, the Flake will be roll.so the best temperature is 80-90ºC)Q: What's the moisture after Horizontal dewatering machine?A: About 1.8%. Adopt Swedeen SKF bearing, with bearing layer on the surface of screw bladesfor longer working life.Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hours

>>

1.8m C, Ku Band Carbon Fiber Flyaway Uplink Antenna

>>

Laser Cleaner 1000W 2000W 1500W laser Rust Removal Cleaning Machine

>>

Yada High Quality 180/200mm Resistant Reusable Bamboo Straws Drinking Wines And Drinks Wooden Bamboo Straw

>>

C6241X1000 Manual Lathe for Metal Cutting with CE

>>

3-pc 1500psi BSPT ISO 5211 DIRECT MOUNTING PAD CF8M BALL VALVE

>>

Pleated Window Screen Retractable Insect Screen Baby Plisse Plisse Screen

>>

Custom Laser Die Cut Carbon EVA Foam and EPE Foam Cardboard Tool Box Packaging Case Insert Foam

>>

Diament Member Grade AA Polyester DTY Yarn 300d/96f for Fabric

>>

German irrigation pipe quick connect hose coupling

>>

Concrete Pump Agitator Motor Hydraulic Motor Mixing Motor Concrete Pump Motor Parts

>>

High Quality CNC Surface Grinder Machine Myk1022 Horizontal Flat Surface Grinding Machine

>>

Tdp Die Custom Mold Pill Press Mould Tablet Press Die Tdp5 Punch and Die Factory Price

>>

Fresh Taro with The EU Qualification

>>

High Precision Vertical Broaching Machine for Efficient Manufacturing

>>

15 kw 12 kw PVC Plastic Welders Equipment High Frequency Tent PVC Window Welding Machine

>>

Hkh Customize Individual Printing Animal Ceiling Kids Room Ricepaper Lantern

>>

Mj6128t Table Panel Saw Wood Working Machine

>>

Integrated Concrete Thickness Measuring Instrument Gauge Floor Slab Thickness Gauge

>>

10ton Pneumtaic Air Winch Approved BV/CCS/API/ISO9001-2008/ABS

>>

stainless steel wire mesh netting machine