Basic Info.

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Product Name

PP/PE Waste Film Washing Line

Application

Plastic Recycling Washing

Automatic Grade

Automatic

Machine Type

PP PE Film Bottle Washing Line

Raw Material

Waste PE PP Film

Water Consumption

0.75-4 T/H

Function

Making Clean Plastic Flakes

Dimension(L*W*H)

According to Model

Key Selling Points

High Productivity

Speed Control

Inverter Control

Core Components

PLC, Motor, Gear

Final Film Flakes Size

30-50mm or Customized

Transport Package

Bubble Film/Stretch Film/Carton Pallet

Trademark

Meetyou Machinery

Production Capacity

50000 Set/Year

Product Description

Zhangjiagang Meetyou Machinery Co., Ltd.

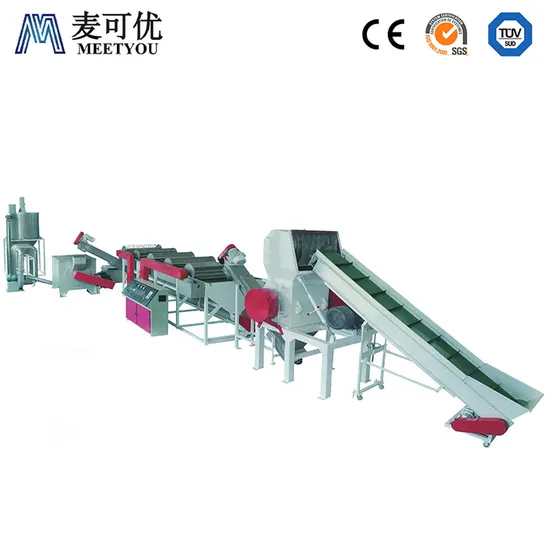

Fully Automatic Two Stage Waste Plastic PP PE Film Bags Recycling Washing Machine Full Line

Product Description

Our fully automatic PE PP film washing recycling line is the ideal solution for your PP/PE film recycling needs. The PE PP film washing line is widely used to recycle plastic like LDPE LLDPE film, PP woven bags, and PP jumbo bags. etc. By our PP PE film recycling line, the final humidity of film flakes will be less than 5%, the film flakes could send to our pelletizing machine to make granules directly. We can supply customized PE PP plastic film recycling solutions according to the client's specific requirements between a capacity of 300kg/hr-2000kg/hr.

Our complete PP PE film line is used for recycling and cleaning waste plastic materials like LDPE agriculture film, LLDPE packaging film, PP woven bags, PP jumbo big bags, etc. We could supply the PP PE film washing line with a capacity between 300kg/h to 2000kg/h. As a professional manufacturer of plastic PE PP film washing lines for over 15 years, we provide customers with one-stop PE PP film washing recycling solutions with our unique structure, professional design, and global service experience. Our pe pp film washing line has received unanimous approval from the plant, greatly improving the plastic pp pe film recycling efficiency and output.

Advantage of Our PP PE film washing line

1. Obtained CE and ISO 9001 certifications.

2. Perfectly remove all kinds of dirty attachments on the surface of materials, such as mud, oil, glue, etc.

3. Easy to operate and has low energy consumption.

4. High efficiency, large capacity, and stable work

5. With 304 stainless steel materials with longevity.

6. Use world-renowned brand components to ensure good quality.

7. Composed of crushing parts, continuous washing parts, and squeezing & drying parts.

8. Could be displayed "I" "L" and "U" shapes according to your workshop?

Working Flow:

Belt conveyor→Crusher→Screw friction washer→Floating washer→ Screw friction washer→Floating washer→Screw conveyor→High-speed friction machine→Screw conveyor→Two direction horizontal separating screw→Squeezer machine→Storage hopper→Control cabinet

Features

The PE/PP film wash line system is designed for washing plastic films with contamination levels exceeding 80% Minimizing the recycling water flow rate and evaporation losses.

The pre-treatment module of the system is equipped wear-resistant design to maximize system uptime.

Pre-shredding and the pre-washing system remove a large percentage of abrasive materials (sand, grit, etc.) to protect the rest of the system.

The shredding system is designed specifically for film materials to create a uniform particle size which is easy for washing and drying.

A high-speed washing system optimized according to the specific material type liberates and separates contamination from film flakes.

Underwater force-washing paddles in our washing tanks maximize the washing efficiency.

Our drag chain discharge device regulates the material discharge speed and minimizes the water volume sent to the drying process with the product.

Mechanical (centrifugal and squeezing) and thermal drying systems control the moisture content of the finished product.

At < 5% moisture the material is suitable for high-quality pelletizing.

Shredding, high-speed washing, and drying stages are optimized to avoid processing which can cause material loss (fines creation).

Intelligent system automation ensures that components' actions are sequenced and monitored.

Therefore, system capacity is maximized, and the system is effectively protected against un-shreddable materials.

Specification

| Model | Production Capacity | Installed Power | Production Line length |

| PE-300 | 300-400 | 85 | 27 |

| PE-500 | 500-600 | 110 | 32 |

| PE-1000 | 800-1200 | 190 | 48 |

| PP/PE waste film washing line |

| Raw material & formulation | PE/PP rural film, twist bag, shopping bag, packing bag, woven bag, etc |

| Capacity range | 300-2000kg/hour |

| Description of the final product | Moisture: below 1% |

| Particle size: 60-110mm |

We know the quality is the life of our company. Our company insists to manufacture all machine units by ourselves in order to control the quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop. Even if some parts are from our certified supplier, our quality inspector will check these parts before entering our warehouse. Detailed Photos

FAQ

Q: What are acceptable payment terms?

A: T/T or L/C at sight.

Q: What is the delivery time for the machines?

A: Usually it will be 50-60 days according to the situation of the order.

Q: What is the warranty time of the machines?

A: It will be 12 months since the acceptance of the machines or 15 months since delivery to the loading port.

Q: What about your after-sales service?

A: Engineers available to make installation, commissioning, training, and providing after-sales service overseas.

>>

1 Ton Per Hour Project Machine Automatic Animal Feed Processing Line Poultry Animal Feed Processing Machine Feed Mill

>>

High Quality Copper Wire Custom Diameter Chainmail Metal Ring Mesh

>>

Burr-Free Cutting Custom Hlg Series Multi-Function Fiber Laser Tube Cutting Machines

>>

Byloo function Fishing Plier Fish Control Catch Fish Line Cutter Fishing Scissors Ring Hook Removal Scissor

>>

Iran Market Applicable Hot Selling Parboiled Rice Mill Parboiled Automatic Rice Mill with Less Broken Rice in Nigeria

>>

Hydrogen Peroxide Plasma Sterilizer H2O2 Low Temperature Plasma Sterilizer Price

>>

160-450mm HDPE Pipe Machine PE Pipe Extrusion Line

>>

BRAND NEW AFTERMARKET 5 SERIES F10 LCI DOOR INNER SEAL WETHER STRIP PARTS

>>

CNC Leather Punching Sewing Machine Multifunction Embroidery Punching Machine for Car Interior

>>

pista nuts pistachio nuts raw pistachios nuts salted roasted with shell

>>

Customized Pig Farm Equipment Pig House Weaned Piglet Nursery Pen Crate

>>

Fish Hunter DV1D VIB 60MM 10G Fishing Lure High Quality Fishing Lures Wholesale Floating Fishing Lure

>>

2.4G Wireless Gaming Headphone Product_ID 742

>>

GE IS200SAMBH1ABA Board

>>

X6332 Universal Turret Milling Machine Vertical Milling Machine

>>

Mill Drill Machinery Drill Mill with Dro Vertical Milling and Drilling Machine Ctzd45 with Variable Speed for Metal Working

>>

Cooking Timer Digital Square Magnetic Large LCD Kitchen Count Up Down Loud Alarm Clock 24 Hours with Stand

>>

MIM Parts for Consumer Electronics - China Metal Injection Molding Manufacturer

>>

MAICTOP AUTO PARTS TRANSMISSION FILTER FOR PRADO UZJ100 VZJ95 OEM 35330-60030

>>

Auto Turbocharger 49477-02122B / TD04LR6-04HR / 15TK31-6.0T