|

US$800.00-1,500.00

|

1 Piece

(MOQ)

|

Basic Info.

Application

Liquid with Suspended Solids, Viscous Fluid, Liquid

Application Area

Chemical

Mixing Drum Shape

Circular Groove

Warranty

1 year, Online Service

Working

Ultrasonic Homogenizer

Separation Mode

Sedimentation Type

Operating Type

Continuous Type

After-Sales Service

Provided

Operating type

Continuous Operating

Transport Package

Wooden Case

Production Capacity

200PCS/Month

Packaging & Delivery

Package Size

45.00cm * 22.00cm * 27.00cm

Package Gross Weight

6.000kg

Product Description

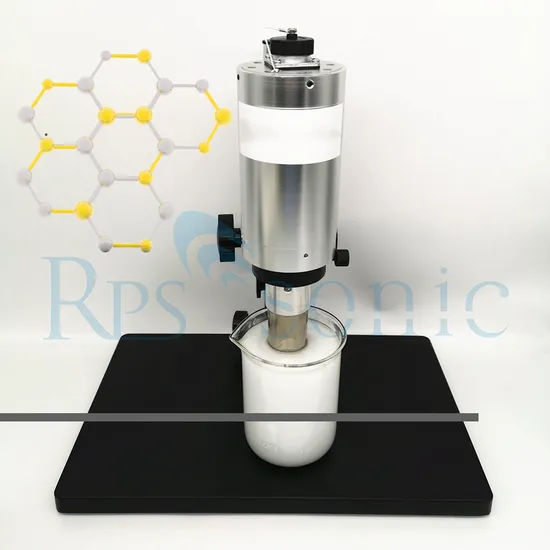

20Khz Ultrasonic dispersion and emulsifier equipment

Model

| SONO20-1000

| SONO20-2000

| SONO15-3000

| SONO20-3000

|

Frequency

| 20±0.5 KHz

| 20±0.5 KHz

| 15±0.5 KHz

| 20±0.5 KHz

|

Power

| 1000 W

| 2000 W

| 3000 W

| 3000 W

|

Voltage

| 220/110V

| 220/110V

| 220/110V

| 220/110V

|

Temperature

| 300 ºC

| 300 ºC

| 300 ºC

| 300 ºC

|

Pressure

| 35 MPa

| 35 MPa

| 35 MPa

| 35 MPa

|

Intensity of sound

| 20 W/cm²

| 40 W/cm²

| 60 W/cm²

| 60 W/cm²

|

Max Capacity

| 10 L/Min

| 15 L/Min

| 20 L/Min

| 20 L/Min

|

Tip Head Material

| Titanium Alloy

| Titanium Alloy

| Titanium Alloy

| Titanium Alloy

|

Power ultrasound is well known for its intense and precisely controllable milling and dispersing effects. Industrial ultrasonicators provide a highly uniform particle size distribution in the micron- and nano-range. Industrial ultrasonicators process easily large volume streams of high viscosities and fulfil a homogeneous wetting, dispersing, deagglomeration and milling.

Paint Manufacturing with UltrasoundFormulation: Whether high viscosities, high particle loads, aqueous- or solvent-based - with Hielscher's industrial inline ultrasonicators you can process any formulation. Micron- and Nano-Size: The cavitational high shear forces reduce particles to minute particle diameters and provide an uniform dispersion. Optical Properties: To obtain the correct optical properties, pigment particle size have to be controlled. Usually, opacity correlates with particle size: the finer the particle size, the more opacity. For example, TiO2 is specifically processed to a particle size of 0.20 to 0.3 micron, which is approximately the equivalent to one-half the wavelength of light. Ultrasonication reduces the TiO2 pigments to their optimum size, so that ultimate hiding is obtained. High-Performance Particles: Smaller particle sizes result in greater colour saturation, colour consistency and stability. The intense, yet precisely controllable ultrasound forces allow for producing modified and functionalized nano-particles, such as coated particles, SWNTs, MWCNTs and core-shell particles. Such particles show unique characteristics and elevate paint or coating formulations to a new level of quality and functionality (e.g. UV resistance, scratch resistance, strength, adhesiveness, high heat resistance, infrared and solar reflectivity). Modified Particles: Surface modified pigments have very low viscosity at high pigment loadings (2.5cP at 10% solids), superior suspension stability and high purityUse ultrasonics for the production of final formulations master batches of pigment paste refining particles after conventional milling Ultrasonic Paint Processing Ultrasonic Processing: 7x UIP1000hdT Information Request Name Email address (required) Product or area of interest Note our privacy policy. Request information For the production of paint, the components such as pigments, binders/ film formers, diluents/ solvents, resins, fillers and additives have to mixed together into a homogeneous formulation. Pigments are the determining component that gives paint its color. The most important white pigment is TiO2, which needs to be milled to a optimum particle size between 0.2 and 0.3 microns in diameter to show the desired grade of whiteness, brightness, opacity and a very high refractive index. The ultrasonic shear forces provide a very effective and energy-effective deagglomeration and dispersion of TiO2 particles (see chart below). Ultrasonic milling and dispersing influences the quality of paint improving its color strength, density, fineness of grinding, dispersion and rheology.

Dispersion of Nanoparticles

Ultrasonic grinding and dispersing is often the only method to process nano particles efficiently in order to obtain primary particles. A small primary particle size results in a large surface area and correlates with the expression of unique particle characteristics and functionalities. At the same time, a smaller particle size is associated with a high surface energy for more severe aggregation and reactivity, so that the intense ultrasonic dispersing forces are required to disperse the nano particles homogeneously into the formulation. Furthermore, an ultrasonic surface treatment can modify the nano particles which leads to improved dispersability, dispersion stability, hydrophobicity and other features. Researchers have recommended the ultrasonic dispersion method for nano particles as preferred solution, "because the material dispersed by the ultrasonic method is much purer than that produced by bead milling.

>>

Taijia rebound test concrete strength digital concrete rebound hammer

>>

2023 Hot Sell 12V Battery Kids Ride Car Children Simulated Electric Toy Vehicle 2023 with Remote Control

>>

Large 2 in 1 Bamboo Chopping Cutting Board With Sharpening Stone For Kitchen

>>

Export to Africa Agricultrue Machinery Tilling Machine Diesel Engine Cultivator Power Tiller

>>

1050ml Gold Sealable Foil Cutlery Disposable Takeaway Pan

>>

200kg-800kg 3m-5m Mobile Glass Loading Machine Vacuum Lifter

>>

Pathology Low-Profile Disposable Blades Leica 819 Histology Consumable

>>

JARCH 2 ~ 24 Conductors Large Bore Slip Rings , Through Hole 500mm slip ring connector

>>

Factory Symons Cone Crusher CS160 4.25′ft Crushing Machine for Basalt Gypsum Stone

>>

2023 latest iphone 14 pro max high quality

>>

Home Gym Commercial Dumbbells TPU Round Dumbbells for Work out

>>

Diverter Valves Asymmetric Hand Operated HVAC System Duct HVAC Duct Air Vent

>>

Sports Venue Decoration Decorative Synthetic Ornamental Leather

>>

CE Proved Rotavator Cultivator Roller Rotary Hoe Tiller, Tlm Series Tlm125

>>

Three Wheels Motorcycle Mini Small Truck Diesel Electric Mining Underground Dump Tricycle

>>

Used Fuso Mixer, Japan Original Concrete Transit Mixer, Used Concrete Equipment for Sale

>>

non woven caps Bouffant Cap , ,single&double elastic with CE

>>

Anti Fog UV Protection Waterproof Electroplate Men Women Swimming Goggles

>>

Floor Type Supermarket Products Advertising Cardboard Display Racks Printed Paper Display Shelf Display Counter

>>

fishing rod butt joint accsesories 2 pieces stix fishing rod fishing surf casting rod