|

US$150,000.00-500,000.00

|

1 Set

(MOQ)

|

Basic Info.

Making Method of Parison

Extrusion-Blow Molding

Computerized

Computerized

Certification

CE, ISO9001:2008

Power Supply

380V Three Phase 50Hz

Application

IBC Tank Water Tank

Extruder

Single Screw Extruder

Extrusion Capacity

330kg/H

Volume

20-2000L Customized

After Service Providede

Engineer Available Service Machine Over Seas

Transport Package

According to Customer Needs

Specification

ce ISO9001 2008

Production Capacity

30 Sets/Year

Product Description

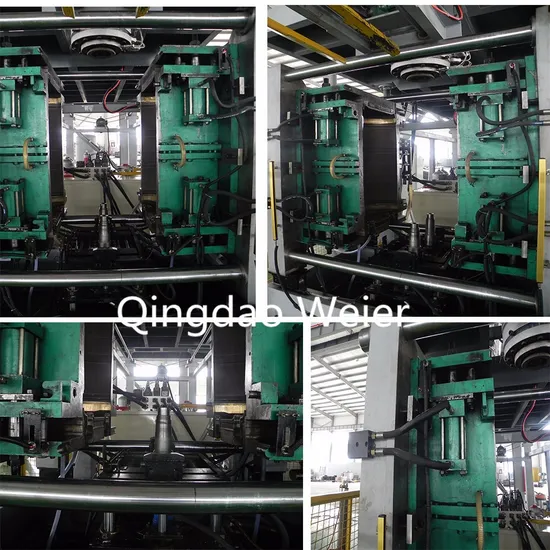

plastic double ring drum IBC water tank blow moulding machine

Single double layer 200 liter plastic drum water storage barrel tank blowing molding machine,mainly used in chemical packing containers.Our company with many years of production experience ,by using advanced production technology,equip with Japanese Moog wall thickness controller and servo valve,also woth dedicated highpreformance industrial PC computer control system,powerfull software function to ensure optimization of process parameters and fault diagnosisi,so that the production and management are more convinient and intuitive.

Our advanced production technology and strict quality management system let our client's products get our national quality inspection and quarantine identified ,respectively,with the" international maritime dangerous good transport rule"1.2 categories of dangerous goods transport standards,access to the "dangerous product quolity packing container permit",base on our stong technical support,improving after sales service.

Main technical parameter of plastic double ring drum IBC water tank blow moulding machine

| System | Item | 220L L ring | 1000L IBC |

| 1 layer | 2 layers | 1 layer |

| Extruder | Screw diameter(mm) | 120 | 100/100 | 110/100 |

| L/D | 30/1 |

| Driving motor power(kw) | 132 | 75/75 | 90/90 |

| Heating power(kw) | 28 | 44 | 52 |

| Extrusion capacity(kg/h) | 330 | 350 | 420 |

| Moulds die head | Materials storage volume(L) | 22 | 45 |

| Parsion control | 100 DOT MOOG wall thickness controller |

| Die lip size range(mm) | 200-250 | 600 |

| Heating power(kw) | 36 | 40 | 50 |

| Moulding clamping system | Mould size(mm) | 1600*1500 |

| Clamping force(kn) | 800 | 1200 |

| Electrical control cabinet | Temperature controlling | Siemens temperature-control modules |

| PLC | Siemens |

| Touching screen | Siemens |

| Hydraulic system | Main oil pump motor(kw) | 37 | 45 |

| Servo motor(kw) | 7.5 |

| Basic Parameter | Outer size L*W*H (m) | 7*4*5 | 9.6*5*6 |

| Total power installed(kw) | 210 | 239 | 281 |

| Average power consumption(kw) | 120 | 143 | 168 |

| Weight(t) | 20 | 24 | 33 |

Electrical parts list of plastic double ring drum IBC water tank blow moulding machine

| Main motor | Siemens |

| Inverter | ABB |

| Temperature control | Siemens |

| Mold of PVC edge band | Customized |

| PLC control | Siemens |

| Programe control | Siemens |

| Other electrical parts | DELIXI |

Detailed description of plastic double ring drum IBC water tank blow moulding machine

1.Save time and effort when replacing the mold,die head with upper machine platform can lift simultaneously,clamping system can be whole remove adjustly,replacement of the molds is safe and convenient

2.Plastizing system:Screw with forced feeding,seperation type structure,to ensure plasticizing effect,increase productivty,and hard gear reducer with stepless frequency control,make screw speed stable,effiecient and reliable

3.Siemens touch screen and PLC control system,man-machine interface,process set to change,retriecal ,monitoring,troubleshooting,are all finished on the touch screen,user-friendly desigh,to make your job easier

Company information

Qingdao Weier Plastic Machinery Co.,Ltd ,the professional manufacturer of plastic machines,which is engaged in macromolecule science,is the director member of WPCC (plastic & wood production council of Chinese plastic community).We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement .

Now we become the test and industrialization centre of plastic engineering technology research institute Qingdao Science and Technology University.At the same time we bring in and absorb advanced processing engineering of foreign plastic machines.To realize chain service of technics and machines.

We have more than 30 machine lines running in China market;Welcome to visit us, and also can show the machine line running in client's factory.

Why choose Weier

1.We are engaged in macromolecule science, is the director member of WPC (plastic & wood production council of Chinese plastic community)

2.We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement.

3.We become the test and industrialization centre of plastic engineering technology research institute of Qingdao Science and Technology University.

4.We bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technics and machines.

5.We have experiences in this field since 1980s

6.We have our production bases for WPC and plastic product in China with large scales, which shows our machine's production power

7.We have strong technical teams and cooperate with China scientific institution to develop, improve and test our machine, to ensure what customers get are the most reliable machines from China.

8.We select the most reliable mechanical and electrical parts for our machine with all famous reliable brands, with European CE certificated.

9.We put our heart into every business with aim of long term cooperation.

10.We have perfect service system-- Our president is devoting himself to pre-sale, on-sale and after-sale service.WEIER JUST DO WIN-WIN BUSINESS!!!

FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

And then pay the 70% balance by TT or irrevocable L/C at sight .Then seller ship the machine.

Q2.How long is the delivery time?

A:For standard machines, it would be 30 days;For non-standard machines and customized machines according

To client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment.We also supply water, electricity, gas of equipment and installation drawing.(2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 50 USD for each engineer will be born by the buyers.We will realize guarantee of repair;Replacement and refund of substandard products within one year after the machine leaves factory.And half a year for electric parts.Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair;Replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation).We guarantee the material of screw & barrel (guarantee without normal abrasion).And half a year for electric parts.Fittings of the machine will supply at preferential price after one year.

Contact us!!!

Qingdao Weier Plastic Machinery Co.,Ltd

Add:Middle Pingcheng road ,East of Jiaoxi Industrial Zone,Jiaozhou City ,Qingdao China.

Contact name:Andy

Mob:+86 15908930795

:+86 13063732322

>>

Universal Automatic Gear Shift Knob Mould

>>

PE Bag Washing Line Waste Plastic Cleaning Recycling Line

>>

Sh101 Sh121 Sh151 Walking Tractor

>>

BHA-5100 Lab Fully Automated Blood Test Machine Automatic 5 Part Hematology Analyzer

>>

Jade jadeite angle convex type technology-CNC computer numerical control machine

>>

Diamond Ultra Thin Turbo Cutting Saw Discs/Diamond Blade/Ceramic Blade/Circular Blade/Cutting Blade 4"

>>

Round Embossed Wedding Gold Colored Feather Glass Charger Plate

>>

155m 622m 1.25g 2.5g SFP Module, 5g 6g 8g 10g SFP+, 25g SFP28, 40g Qsfp+ 50g 100g Qsfp28 Transceiver SFP

>>

1000L Automatic Extrusion Plastic Large HDPE Drum Tank Barrel Making Blow Mold/Mould Machine

>>

Custom Logo Cooling Only 5000Btu To 18000Btu Air-Conditioning Portable

>>

Large Professional Amusement Park Games Play Kids Non Standard Outdoor Stainless Steel Playground for Sale

>>

ASTM D4693 Automobile Ball Bearing Grease Low Temperature Torque Tester

>>

Poultry Farm Broiler Deep Litter System With Automatic Pan Feeding Line

>>

Yvf2-100L2-4 3kw Special Three-Phase Asynchronous Motor for Variable Frequency Speed Regulation Electric Motor with CE Approval

>>

94% Purity Industrial Grade Sodium Tripolyphosphate STPP

>>

Advanced Hydraul Mini Excavator for Construction with Bucket

>>

Good Price Medical Cosumable Injection Cap Plastic Moulding Machine

>>

China catalytic converters for Audi Q7 Catalytic Converter

>>

brass wedge

>>

Wholesale Price Clear Medium Wave Carbon Fiber Heating Tube 750mm 220v 1200w