|

US$10,000.00-30,000.00

|

1 Set

(MOQ)

|

Basic Info.

Computerized

Computerized

Diamter of Screw

60/65/72/75/95mm

Transport Package

Packing in Wooeden Case

Specification

15mx2mx2.5m

Production Capacity

400 Kg/H

Product Description

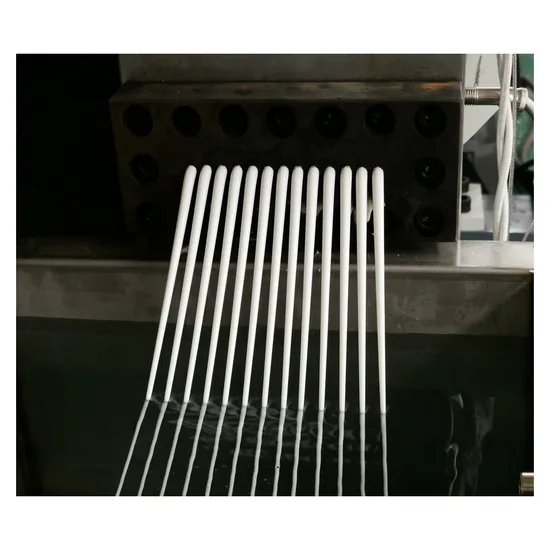

Plastic Cold Cut Recycled Pelletizing Granulator Machine

Product Application on Plastic Cold Cut Recycled Pelletizing Granulator Extrusion Machine SJMS series Plastic Co-rotating Parallel Twin-screw Granulating Machine Parallel double screw granulating machine is composed of parallel twin-screw extruder, granulating die head, granule cutting machine, three-grade air supplying system, storage chamber. Also it could be designed to use single screw extruder to finish the cold cut granulation.

Main Features on Plastic Cold Cut Recycled Pelletizing Granulator Extrusion Machine 1)The parallel twin-screw pelletizing adopts modular construction, with advantages of all gear-closing and strong self-cleaning.

2)The granulating barrel has a good exhaust effect. The bi-metal alloy bushing is of war-resistance and corrosion-resistance.

3) The machines can be combined free according to the characteristics of materials and production process, so it is widely use.

4) Granulating die head is made from high-quality mould steel, under hard chrome plating treatment. The reasonable-distributed material running channel can ensure the uniform extrusion of the granules without mutual influence.

5) The unique three-dimensional cooling structure and the new-type multi powerful blower cooling mode make the cooling effect better.

6)Besides, the pelletizer precise cutter ensures the even and smooth surface of the products. The speed frequency regulation meets different material granulating requirement.

Plastic PP/PE/PS/PC/ABS Cold Cut Recycling Granulating Pelletizer Production Line: Automatic spiral material feeder, 1 set

SHJ-60~95 parallal double screw extruder, 1 set

Electricity control system, 1suit

Extruder stretching pelletizing machine, 1 set

Water cooling tank, 1set

Blow dryer, 1 set

Finished granule conveying unit, 1set.

Detailed working conditions:

1, Electricity: 380V, 50Hz, 3-phase or other area local requests on the inducstrial electricity policy.

2, Water consumption:

2.1: Inner circulating water: the machine processing craft requires barrel cooling with circulating water, the water medium should be soft water (distilled water), to prevent incrustation, do not use tap water

2.2: Outer circulating water: to cool down the inner recirculating water. Water source: 1) can make a 10~30 m3 water pond out of the workshop wall according to actual condition, drawing water by water pump to form outer circulation water 2) can also be connected with tap water directly, but would cost large waste

3, After the machinery installed and tested qualified, the buyer should change the engine oil of the transmission case in the third month, and next time to change engine oil should be on the sixth month, later on the engine oil should be changed annually.

OUR servies Pre-sale services

1.Provide the free consultation of the machine

2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

Services during the sales

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Inspect the machine before leaving the factory.

3.Send our experienced workers and engineer to your factory for installing and adjusting all the machine

4.Train the first-line operator.

5.Provide the basic formula

After sale services

1.One year warranty

2.24 hours online service

3.Engineers available to service machinery overseas

4.Provide technical exchanging

If you are interested in our machine,please contact me at any time.

OUR company

>>

Custom Logo Metal Gold Plating Brooch Enamel Hat Lapel Pins

>>

PVC, PE, PP, PC, TPU, EVA Plastic Pulverizer

>>

Marya Pharmaceutical Industry Vial Liquid Washing Filling Stoppering Capping Machine Vial Bottle Filling Production Line with Sterile Isolation System

>>

100mm 10bar General Pressure Gauge G1/2

>>

B07 Dual Spindle Swiss CNC Bench Lathe Machine with Drill Boring Functions

>>

Medium Voltage Power Cables N2xsy, Na2xsy, N2xs2y, Na2xs2y Cables

>>

High Quality Factory Customzied PVC Artificial Synthetic Leather for Sofa Covers Furniture

>>

High Quality Sf Ink for Duplicator Sf5030, 5130, 5050, 5230, 5250, 9250, 9350

>>

Climate-Adaptive Adobe Brick Machine Packages for Arid Regions with Evaporative Cooling Brick Formulations and Sandstorm Resistance Treatments

>>

Microcrystalline Wax Oil Content Tester Volumetric Method

>>

Eco-Friendly Kraft Paper Tea Bags for Freshness and Flavor Retention

>>

0.8mm Steel Sheet for Decorative Wall Panel Exterior Wall Devorative Panel Wall Board

>>

Horizontal Hospital Medical Open Ended Transparent Plastic Testing Test Tube Making Machine Cuvette Injection Production Line for Taking Blood and Body Fluid

>>

Children′s Apparel Factory Customized Boys Girls Fashion Casual Sweatshirt 350g Hight-Quality Outside Street Kids Clothing Hoodies Set

>>

RSQ7 Car Bumpers For Audi Q7 Upgrade SQ7 RSQ7 Front Bumper Grille Bumper Trims Flog Lamp Grille Body Kits 2012 2013 2014 2015

>>

Chinese New Mini Crawler Digger Excavator Machine Mini Bagger CE EUR EPA Engine 1t/2t/2.5t/3.5t Mini Excavator

>>

Numerical Control Milling Vertical Milling Machine CNC Precision Bench Lathe

>>

Optical System Olympus Microscope Cx23, Olympus Cx43 Biological Microscope Cx33 Olympus

>>

Stable Running Top Quality Airport Supermarket Moving Walk Escalator

>>

EFD15,EFD20,EFD25,EFD30 transformer clips, stainless steel clamps