Basic Info.

Making Method of Parison

Extrusion-Blow Molding

Computerized

Computerized

Certification

CE, ISO9001:2008

After-sales Service

Commissioning and Trainingengineer Available

Outer Packing

Customization

Transport Package

Wooden Case or Film Wrapping

Production Capacity

1000 Sets Per Year

Product Description

Product Description

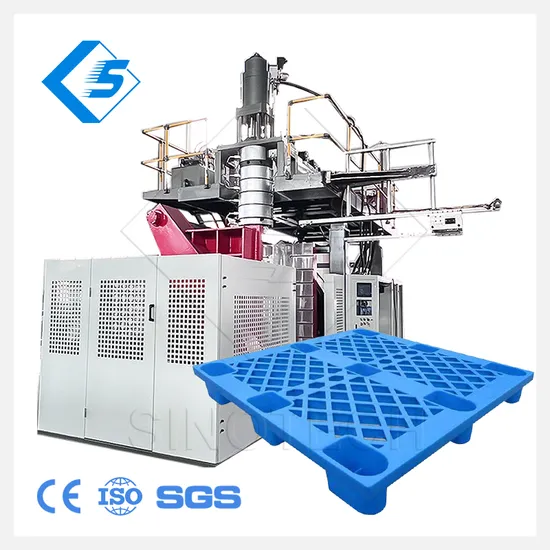

Modular Floating Plastic Dock Extrusion Blow Moulding Machine

STS-135L series,This is our hot sale series machine. This machine is suitable for the plastic pallets.The main parts of this machine are designed and manufactured by ourself.We do the independent R&D and inspection.If you have other special requirements,we can provide customized services for you.

STB-135 Accumulator Extrusion Blow Molding Machine

Machine Features

1. Special design for Nine corner plastic pallets. 2. Die head design with easy to change the material and color.

3. Latest mold changing system, much faster and easier.

4. Optimized hydraulic system, proportional pressure control

5. Adopts two pull-rod type closing-mold devices by rack and pinion system. The large setting platen is suitable for various sizes of molds

6. Simple structure in linear type, easy in installation and maintenance.

7. Servo system

8. With robot arm take out the finished product

9. One to three multi-layers choose 10. Hydraulic and electric hybrid power design, makes the machine run more speed and more energy-saving

11. Full Servo system control.

12. Simple structure in linear type, easy in installation and maintenance.

13. With a robot arm take out the finished product.

14. Single die-head and Single station.

Product Parameters

Technical Specification

| STB-135 Accumulator

Extrusion Blow Molding Machine

|

Specifications

|

| STB-135

|

Machine Weight

| T

| 35

|

| Machine Dimension(L*W*H) | M | 9.0*6.5*7.8 |

Average power Consumption

| KW

| 100

|

| Die Head |

Number of Heating Zone

| Zone

| 8

|

Power of Die Heating

| KW

| 56

|

| Max. Die-pin Diameter | mm | 950 |

Extruder Unit

|

Screw Diameter

| mm

| 135

|

Screw L/D ratio

| L/D

| 30:1

|

No. of Heating Zone

| Zone

| 21KW*6

|

Heating Power

| KW

| 88

|

Screw driving power

| KW

| 160

|

| Clamping Unit |

Mould Size(W*H)

| mm

| 1300*1300

|

| Mould thickness | mm | 1200 |

| Mould Platen Size(W*H) | mm

| 1500*1500

|

| Opening and Closing stroke | mm | 800-2200 |

Clamping Force

| KN

| 2000

|

| Power |

Total Power

| KW

| 320

|

| Blowing pressure | Mpa | 0.6 |

| Average power consumption | KW | 100 |

Our Advantages

Company Profile

Certifications

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's the advantage of SINOTECH? We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

>>

2023 New Design Men Outdoor Riding Glasses UV Protection Polarized Sport Cycling Fishing Sunglasses Women

>>

cremation machine human crematory burner equipment furnace on wheels

>>

Bathroom Accessories Latest Design Rain & Handheld Shower Heads High Pressure Round Shower Heads

>>

PLC Centerless Grinding Machine L600 for Bearing Rings, Bars, Shaffts

>>

T-Measurement UTG21-R Ultrasonic Fuel Level Meter Fuel Level Monitoring

>>

Modified to double row dragon scale LED taillamp taillight rear lamp light for BMW 2 series F22 F23 F87 tail lamp 2014-2021

>>

sma cable rg405 male to male rg402 cable jumper for sma male WiFi Antenna Extension RF Coax Cable Adapter Jumper for Wi-

>>

White POM Acetal Plate Sheet

>>

Concret Mixer 400L with Drum Diesel Cement Mixer Mobile Concrete Mixers

>>

High Performance 12V 4A Sealed Maintenance-Free Motorcycle Battery

>>

tube wholesale taiwan fishing rod tackle carbon fishing 10h light bamboo fishing rod chinese suppliers

>>

Non-Woven Machine Carding Waste Fiber Polyester Fiber Carding Machine Production Line

>>

Hand Push Gasoline Garden Cultivators 52cc Mini Tiller TM-Wg520A

>>

Spot Colour Coated Aluminium Zinc Plated Coil PPGL Fluorocarbon Coating 1250mm Width Fade Resistant 15 Years

>>

Ls-300yt Agricultural Trolley Sprayer Gasoline Engine Sprayer Machine with Wheelbarrow

>>

2022 Hot Sale New Design Wooden Inflatable Stand Up Paddle Board Sup Boards Inflatable Stand Up Paddle Board Pink Color for Lady

>>

Direct Sale Stainless Steel Water and Chemical Storage Tank

>>

Module spare parts DS200SIOBH1AAA

>>

High CCO Flux Cored Welding Wire for Wear Plate Hardfacing & Gas Shielded Welding Metal & Metal Products

>>

Original New LTE BG96 Cat M1/NB1/EGPRS Module, NB-IoT Module BG96