|

US$10,000.00-50,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Type

Worktable Milling Machine

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Automatic

Certification

CE, ISO 9001

Max. Load Capacity of Table

800 Kgs

Max. Travel Longitudinal (X)

900 mm

Max. Travel Cross (Y)

650 mm

Customized Production

OEM or ODM Manufacturing

Motor Rating X-Axis Feed

15 Nm (Servo Motor)

Motor Rating Y-Axis Feed

15 Nm (Servo Motor)

Motor Rating Z-Axis Feed

18 Nm (Servo Motor)

Transport Package

Standard Export Packing

Specification

CE, SGS, ISO, TUV, CQC

Trademark

MAXNOVO MACHINE or OEM

Production Capacity

More Than 1000 Units Per Year

Product Description

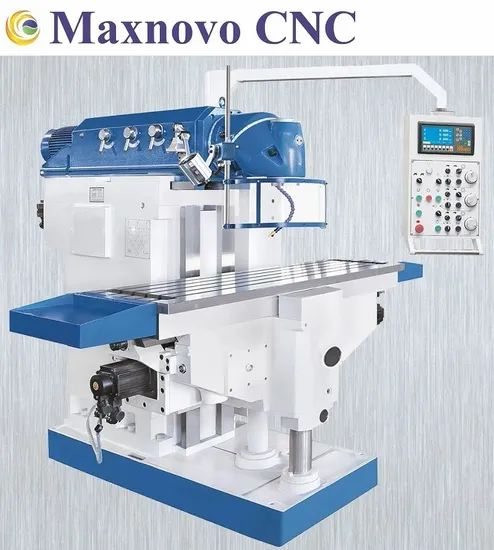

MM-UWF10S - Vertical Powerful 5500W Universal Milling Machine - MAXNOVO MACHINE

This kind of MM-UWF10S is Servo Motor Drive Universal Milling Machine, with a solid heavy grey cast iron construction making this high precision RAW Milling Machine ideal for heavy duty machining of oversize work-pieces. Features of this swivel head proven universal milling machine include Servo Motors Drive in all three axes, Ball Screws in all three axes, ISO40 spindle taper, 5500W powerful main motor, Electronic Hand-wheels integrated in swivel-able control panel, extra large work table and long travel.

Product Description

Heavy-duty Universal RAW Milling Machine Features Long Travels on all axes and with a proven Universal Swivel Head, include Servo Motors drive and Ball Screws on all Three Axis

Main Feature :

Convincing Arguments : Quality, Efficiency and Price Table size 1235 X 460 mm, Spindle taper ISO40, Main Motor 5500W Max. Load Capacity of Table is 800 KGS Preload Ball screws on all Three-axes with ZERO backlash for easy and precise feeds Dynamic infinitely variable speed and rapid feed driven by powerful, separate Servo Motors on every axes (all X-/Y-/Z-axis) Large dovetail guiding X-axis, rectangular guiding in Y-axis and Z-axis guarantees stability Large cross table with T-slots treated surface for heavy work-piece load Machine body in heavy cast iron construction for vibration-free run Clearly arranged spindle speed control unit on machine arm Turcite-B coating in X-axis reduces slip-stick effect Electronic Hand-wheels integrated in swivel-able control panel for easy operation Stepless feed settings and rapid feed in all three axis driven by Servo Motors Optimal adjustment spindle speed and feed for economic machining of various materials Precise dovetail guides on X-axis, wide square guides on Z-axis Ball screws in all three-axes to guarantee high accuracy and minimize play Central lubrication for 3-axis (X/Y/Z-axis) are standard equipment Central lubrication for guide-ways comes standard Double supporting column for big load and high accuracy Mechanical change speeds in head stock for powerful machining capacity Swivel milling head can machine any angle surface through front half-sphere Extra large work table and wide travel ranges on all Three-axes Universal swivel head - cutter can be moved to any spatial angle Hardened, nitrated and polished gear wheels in oil bath Rigid torsion-proof construction with additional guide columns for constant precision when machining heavy work-pieces 3-axis Digital Position Indicator is optional special spare parts Universal milling head swivel 360 degree can be set to various angles Fine-stepped spindle gears for powerful machining Certificate of Original (CO, FORM A, FORM E, FORM F)

Product Parameters

Technical Data :

| Product Name : | Universal Milling Machine with Servo Motor and Ball Screws |

| Product Item : | MM-UWF10S |

| Working Area | |

| Table Size : | 1235 X 460 mm |

| Max. Load Capacity of Table : | 800 KGS |

| Number of T-slot : | 5 Pieces |

| T-slot Width : | 18 mm |

| T-slot Spacing : | 80 mm |

| Milling Head | |

| Spindle Taper : | ISO 40 |

| Spindle Speed : | 30-2050 RPM (27 kinds) |

| Milling Head Swivel Range : | 360 degree |

| Distance from Spindle Nose to Table Surface : | 50-500 mm |

| Throat : | 36 -686 mm |

| Travels | |

| Max. Travel Longitudinal (X) : | 900 mm |

| Max. Travel Cross (Y) : | 650 mm |

| Max. Travel Vertical (Z) : | 450 mm |

| Feeds | |

| Feed Speed Horizontal (X) : | 10-1000 mm/min (variable speed) |

| Feed Speed Cross (Y) : | 10-1000 mm/min (variable speed) |

| Feed Speed Vertical (Z) : | 6-640 mm/min (variable speed) |

| Rapid Feed X-axis : | 2200 mm /min |

| Rapid Feed Y-axis : | 2200 mm /min |

| Rapid Feed Z-axis : | 1100 mm /min |

| Drive Capacity | |

| Main Motor : | 5500 W |

| Motor Rating X-axis Feed : | 15 Nm (Servo Motor) |

| Motor Rating Y-axis Feed : | 15 Nm (Servo Motor) |

| Motor Rating Z-axis Feed : | 18 Nm (Servo Motor) |

| Gross Weight : | 4000 KGS |

| Packing Size : | 2420 X 1850 X 2100 mm |

| Standard Accessory : | Servo Motor in all Three-Axis (X/Y/Z-axis),

Coolant System,

Ball Screws in all Three-Axis (X/Y/Z-axis),

Central Lubrication,

Universal Swivel Head,

Work Lamp,

Tools and Toolbox |

Our Advantages

Guarantee of Quality

The excellent quality is our dignity. All MAXNOVO MACHINE products are produced with high quality standards.

There are same or similar products on the market, however, those products could not meet the MAXNOVO MACHINE strict quality.

Our products are convincing by outstanding quality, accurate manufacturing and at a cost-efficient price and trustable performance. Well trained quality control department is the first contact for adhering to quality on site.

They are responsible for the dimensional accuracy of the components as well as their control and the quality of the manufacturing process.

A team of quality control engineers directly influences the production process on site by regular training courses and tests.

What is more, they are closing working together with the technical department in the factory.

Due to this intensive care at the production site we are able to achieve literally the MAXNOVO MACHINE. The Metal Scraper Craftsmanship is one of the most important techniques in machine tool industry. To make sure the surface perfectly flat

and smooth, we repeat check and scrap by hand with Time-Proven Unique Techniques that passed on to generations.

At MAXNOVO MACHINE, we strictly enforced that all our contact surfaces must be scrapped with at least 20 spots per square inch

and 40% of contact rate. This can guarantee the True Geometric Accuracy for our high precision machines . Casting is the core of machines, we underscores the importance of its development and production.

At MAXNOVO MACHINE, each casting piece passes various tests, such as high-pressure spray, annealing furnace,

and stress release to assure its stability. This can guarantee all customers with excellent quality of machine parts. The Excellent Quality is our dignity. At MAXNOVO MACHINE, our team is insisting on examining every single part of work-pieces

with strictly high quality standards. In order to fulfill the Large-scale manufacturing requirements in various machine tools, we invested a great deal of resources

and man power in innovating its manufacturing technology. At MAXNOVO MACHINE, the whole machining line is completed

in a temperature-controlled environment so as to maintain this outstanding quality and excellent accuracy.

High Precision Milling Machine for Demanding Users !

FAQ :

1.Question : Can you do OEM ?

Answer : Yes, we have the ability to do OEM / ODM to meet clients' requirements.

2.Question : How can I get some product samples ?

Answer : We are honored to offer you good product samples. New clients are expected to pay for the product sample cost and the international transportation cost. Product Sample cost would be deducted from the customers' next mass production purchase order in future.

3. Question : How does your factory do regarding quality control ?

Answer : Assuring Quality is our dignity and quality control engineers specially be responsible for quality checking in each process such as Incoming Quality Control , In Process Quality Control , Outgoing Quality Control , Environment Control, Product Traceability System , Internal Audits & Calibration, Equipment Control & Maintenance , Control of Non-Conforming Materials and etc.

4. Question : What is the average delivery time ?

Answer : Most of the time, it would be around 1 -- 2 month since after confirm receiving customers' contract money. For mass production purchase order at big quantity, the delivery time could be discussed with each other case by case.

>>

Liuzhou wuling LJ4A15Q petrol engine auto car parts

>>

Plant Use 1-2t/H Biomass Wood Pellet Complete Production Line Price for Sale

>>

China Precision Key Type Inflatable Air Expanding Shaft Manufacturer Price 12inch Pneumatic Board Type Air Shaft for Unwinder

>>

Wholesale Velvet Necklace Pendant Gift Box Jewelry Gift Box

>>

Custom Logo Bamboo Branded Gold Wood Shape Blank Custom Opener with Handle Logo Wooden Beer Keychain Bottle Opener

>>

Fein Titanium Bi-Metal Oscillating Saw Blade

>>

Mining trommel screening plant compost trommel multi screen for sale

>>

FRP/GRP High-Strength Chemical Drinking Water Winding Process Fiberglass Pipe, Large-Diameter FRP Pipe

>>

Customized large gear ring dryer flywheel gear ring refining equipment non-standard large gear ring

>>

OEM Car Front Bumper with Whole Carbon Fiber Customization

>>

6mm, 8mm Finished Size, 96% Shape Rates, Competitive Priced Wood Pellet Machine

>>

Compression F Plug Connector for RG6 Coaxial Satellite & TV Cable

>>

High Precision Penetrating Coating Ultrasonic Thickness Gauge

>>

China Factory ANSI B165 ASTM A105 A106 Carbon Steel Forged Welding Neck Flange

>>

Hot Sale High Quality 3 Die 6 Blow for Fastener Production Line

>>

auto electrical parts 261501570 261500791 door controller for chinese bus

>>

Circular Knitting Stype Jacquard Beanie Knitting Machine

>>

Premium High-Performance Auto Oil Pan for Vehicle Maintenance

>>

Pure 100% Cashmere Sweater Knitting Women Hoodie Pullover Elegant Detail Raglon Sleeve Hooded Knitwear

>>

low sulphur calcined petroleum coke/CPC/GPC for graphite electrode/steel plants/casting/metallurgy