|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Double-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

3900x2110x2100

Production Capacity

1000/Year

Packaging & Delivery

Package Size

390.00cm * 210.00cm * 210.00cm

Package Gross Weight

7800.000kg

Product Description

Product Description

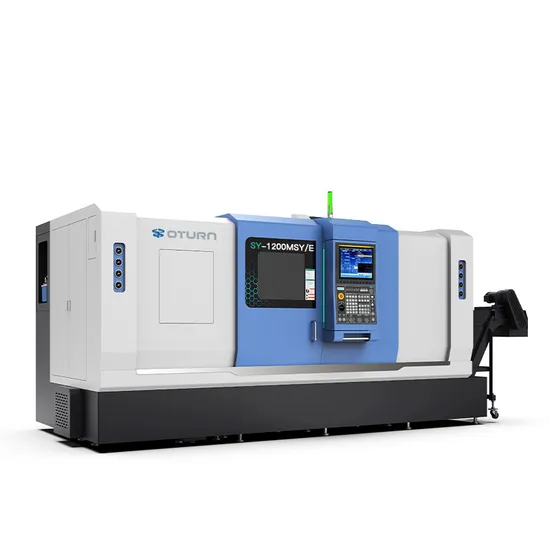

The two-axis lathe can process both ends of the workpiece at the same time in one clamping, which greatly simplifies manual operations, increases output and reduces processes. The second spindle enables full turning and expressly transfers workpieces during machining, thereby reducing cycle times. The machine adopts an optimized 30-degree inclined structure design, which also has high precision, super rigidity and excellent cutting stability. The strong structural lathe bed is made of one-piece high-strength HT300 cast iron and uses finite element analysis. The overall mechanical rigidity and stability are excellent, and it can maintain long-term reliable accuracy, improve processing stability and tool life, and stress relief treatment improves accuracy stability. The high-strength roller linear rail design structure, the transmission system adopts screw pre-tension design to improve the rigidity performance, and the simple and elegant appearance is in line with the trend of the trend. Main features of this machine tool: 1. Adopt direct drive synchronous electric spindle device: magnetic ring incremental encoder (sine and cosine) positioning accuracy: 20 arc seconds, C-axis indexing accuracy: 40 arc seconds. Effectively eliminate spindle vibration, and the nose deflection accuracy is within 0.002MM. Improve the surface finish of the workpiece, adopt a rear-mounted rotor, which makes installation and maintenance faster, the spindle motor is equipped with a cooling system to suppress the influence of thermal displacement and ensure a constant operating temperature of the spindle. The spindle system has undergone strict dynamic balance testing. The good accuracy retention, high rigidity and high efficiency enable the whole machine to not only complete finishing, but also perform rough machining and heavy cutting for users. It is especially suitable for mass production of complex shapes and high smoothness. product. 2. High rigidity integrated design servo power turret. It helps the servo turret's rapid and accurate tool changing performance, and when coupled with the power milling of a high-speed power axis, it achieves excellent turning and milling combined processing capabilities. The tool holder is installed using a high-rigidity BMT installation interface, and the power transmission shaft is driven by a servo spindle motor. 3. The machine tool is equipped with roller linear guides and ball screws. The heat-treated and precision-ground ball screws can ensure the best accuracy and durability. Each axis adopts a direct transfer axis structure and a double-anchor pre-relay method, which can make the heat The amount of displacement is minimized, greatly improving processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain intact accuracy when the machine is subjected to impact, and the displacement is smooth and low-noise, which can extend the service life. 4. This machine provides users with a complete hydraulic and lubrication system, using high-quality hydraulic pumps, hydraulic valves and other components to greatly reduce the failure rate. The hydraulic and lubrication systems are designed to be simple and reliable. 5. It adopts Taiwan rotary chuck cylinder and optional automatic chip removal device, which can greatly reduce the labor intensity of the operator and achieve safe and efficient production. The above functional components can be programmed and controlled, and various functions can be designed and installed according to the special requirements of the user. A special fixture. Product Parameters

| Item | Name | Unit | SY1200MSY |

| Travel | The largest diameter rotating bed | mm | Φ800 |

| Max. processing diameter | mm | Φ480 |

| Max.Swing Over Cross Slide | mm | Φ450 |

| Max. processing length | mm | 970 |

Main-Spindle

Hydro cylinder

Chuck | Spindle nose | type | A2-8 |

| Max. speed of spindle | rpm | 2200 |

| Hydraulic Cylinder/Chuck | lnch | 10″ |

| Spindle hole diame | mm | Φ86 |

| Bar diameter | mm | Φ72 |

| Spindle motor power | kw | 24 |

| Spindle motor power | Nm | 160-390 |

Sub-Spindle

Hydro cylinder

chuck | Spindle nose | / | A2-6 |

| Max. speed of spindle | rpm | 4300 |

| Hydraulic Cylinder/Chuck | / | 8" |

| Spindle hole diame | mm | Ф66 |

| Bar diameter | mm | Φ52 |

| Spindle motor power | kw | 18/22KW |

| Spindle motor torque | Nm | 105-227 |

| X/Z/S axis feed | X/Z travel | mm | 280/1070 |

| Y/S travel | | 120(±60)/800 |

| X/Z/S axis rail specification | spes | 45/45/35(Roller) |

| X/Z shaft wire specifications | mm | 4012 |

| X/Z/Y/S motor power | kw | 2.9/2.9/1.8/2.9 |

| Positioning accuracy | mm | ±0.005 |

| Repeat positioning accuracy | mm | ±0.003 |

| X/Z/S axis moving fast | m/min | 24/24 |

Servo drive

Cutter | The knife tower type | pcs | BMT65-12T |

| Power cutter tower motor | Kw/Nm | 5.0/47.7 |

| Max.speed of | rpm | 5000 |

| The knife biock specifications | mm | 25X25 |

| Circular cutter holder specification | mm | Φ50 |

| The adjacent tool change time | sec | 0.2 |

| Positioning accuracy | / | ±2" |

| Repeat positioning accuracy | / | ±1" |

| Mechanical Size | Machine size | mm | 3900x2110x2100 |

| Machine Weight | kg | 7800 |

| Other | Cutting fluid tank volume | L | 300 |

| Cooling water pump power | W | 750 |

| Volume of hydraulic unit box | L | 40 |

| Hydraulic oil pump motor power | kw | 1.5 |

| Volume of lubricating oil tank | L | 2 |

| Auto lube pump motor power | W | 50 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1:How can l choose the most suitable machines?

A: Please tell me your specifications, and we will help you select the best model, or you can choose the exact model yourself. Alternatively, you can send us the product drawings, and we will recommend the most suitable machines for your needs.

Q2: What are the main products of your company?

A: We specialize in all kinds of machines, such as CNC Lathe Machine , CNC Milling Machine, CNC Turning Machine, Vertical Machining Center, Horizontal Machining Center, Lathe Machines, Turning and milling composite processing so on.

Q3: Where is our factory located? How can l visit there?

A: We have 5 factories located in Guangzhou, Quzhou, Ningbo, and Guangdong. You are warmly welcome to visit us.

Q4. How do you transport it?

A: Provide Transportation Solution DDP/CIF/FOB/FCA.

Q5: What are the Payment Terms?

A: T/T, 30% initial payment when ordering, 70% balance payment before shipment.

Q6:What's the OMQ?

A: 1 set. (Only some low cost machines will be more than 1 set )

We want to know:

1. We strongly suggest you tell us the size, and material of your workpiece for our evaluation, if possible, better to send us a workpiece drawing so that we can recommend you the most suitable model.

2. If need a CIF Price, please kindly tell us the port of destination.

>>

Sliding windows certified by AS2047,AS2208 with double glazed

>>

Supply Organic Chemical Food Grade CAS No. 77-92-9 30-100 Mesh Ca/Citric Acid Anhydrous

>>

Laminator Machine for A3 OL387 Thermal plastic laminator Machine for Home Office School Use

>>

High Quality Agricultural Machine 1ly Series 18-160HP Tractor Trailed 3 Point Hitch 2-6 PCS Disc Plow Plough From China Manufacturer Factory

>>

High Quality TPU Transparent Silicone Strap For Apple Watch Case Band Mate for Apple Watch Band Clear Rubber for iwatch 38/44mm

>>

BTG-UK2 Thermostat Guard for Air conditioner Thermostat Temperature Control Plastic Box Cover Case With Lock Key Good Quality

>>

High Quality 1080P 8 channel mdvr truck car mobile dvr mdvr 4ch 8ch 4g / gps / wifi 4 cams for vehicle

>>

Lenado 9700 Long Life Customize New Product High Precision Popular Flannelette Loom

>>

Alonmax Sample Free Heavy-Duty Three Phase Energy-Saving Ie5 AC Electric Motors

>>

CNC Vertical Machining Center Vmc967vs High Speed Universal Vertical Machine Center

>>

Seed Harvester Melon Shelling Machine Vegetable Seed Extraction Machine

>>

Chuck Open Push-On Type Tyre Inflating Tool Tire Inflating Equipment

>>

30g round cream bottle spot 50ml full cover square cover liquid foundation glass bottle 100ml press lotion bottle

>>

Ce Middle Speed Needle Punching Machine for Floor Mattress

>>

Automatic Manual Oil Filling Palm Plastic Carry Bag Cutting Portable Hydraulic Press Ram Hole Punching Trimming Machine

>>

Utility Hunting Tactical Knife Outdoor EDC Tools 12 Swiss Gear Keychain Pocket Camping Outdoor knives Cutter Multi-Tool knives

>>

Hot Selling Low Price Automatic Granite and Stone Sand Mining 6cx European Jaw Crusher

>>

504014232 Crankshaft Oil Seal for Perkings Engine

>>

Large Plastic Garden Plastic Flower Pots Planters for Home Decoration

>>

FUJI China Factory Home Lift Villa Elevator Passenger Elevator