Product Details

Product Description

Product Description

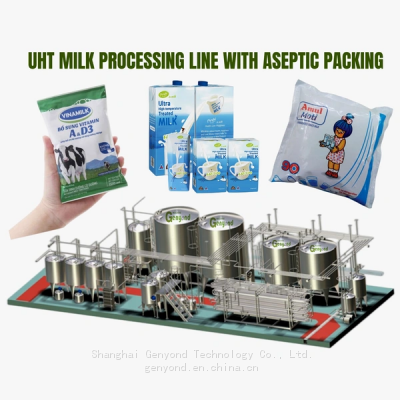

UHT milk processing line with aseptic packing

UHT milk processing equipment includes UHT sterilizer, high pressure homogenizer, milk refrigeration tank, finished product tank, etc. The milk can reach aseptic state after being processed by UHT equipment, and the shelf life is up to 6 months with secondary filling and sterilization. It solves the problem that milk can not be preserved for a long time. UHT tubular sterilizer and high-pressure homogenizer can ensure the long shelf life of milk and the taste quality of milk. Moreover, it can be connected with aseptic packaging machine seamlessly. Our UHT unit PLC automatic control, and high heat recovery, less energy consumption, CIP cleaning, sterilization temperature accurate and reliable, steam flow, cooling water flow, material flow are strictly controlled, all accessories can use the world famous imported brands, to ensure the highest use quality of the equipment.

Output: 200-5000l / h

Final product packaging: plastic bags, plastic bottles, aseptic brick carton , etc.

DescriptionComplete UHT Milk Processing Line

With a product that can be stored for long periods without spoiling and with no need for refrigeration, there are many advantages for both the producer, the retailer and the consumer.

This includes expensive products such as milk, cream, desserts and sauces.

In a modern UHT milk production line (Ultra High Temperature) is pumped through a closed system. On the way it is preheated, highly heat treated, homogenized, ultra highly heat treated,

cooled and packed aseptically. Low acid (pH above 4.5 – for milk more than pH 6.5) liquid products are usually treated at 135 – 150C for a few seconds holding, by either indirect heating

or direct steam injection or infusion. High acid (pH below 4.5) products such as juice are normally heated at 90 – 95C for 15 – 30 seconds holding. All parts of the system downstream

of the actual highly heating section are of aseptic design to eliminate the risk of reinfection, include aseptic packaging in packages protecting the product against light and atmospheric oxygen.

Ambient storage is normal.

Various UHT milk processing systems:

There are two main types of UHT systems on the market.

- In the direct systems the product comes in direct contact with the heating medium, followed by flash cooling in a vacuum vessel and eventually further indirect cooling to packaging temperature.

The direct systems are divided into:

•steam injection systems (steam injected into product),

•steam infusion systems (product introduced into a steam-filled vessel).

- In the indirect systems the heat is transferred from the heating media to the product through a partition (plate or tubular wall). The indirect systems can be based on:

•plate heat exchangers,

•tubular heat exchangers,

•scraped surface heat exchangers,

Furthermore it is possible to combine the heat exchangers in the direct systems according to product and process requirements

Composed by below part :

-- Milk Tank: The milk tanks are the prime components in any milk processing plants that used to store raw milk, skimmed milk, favor milk or cream.

-- UHT Sterilizer: the process of heat treatment to reduce enzymatic activity and kill pathogenic bacteria. The main purpose of ygt pasteurization in dairy plants is to

make the product safe for use and to extend product shelf life.

-- Homogenizer: improves the texture, taste and viscosity of cream or milk-based drink and prevents sedimentation in the dairy products.

-- Filling system: by aseptic filler to guarantee the clean air circulation and match aseptic package, to prolong the shelf time. with optional by Tetra pak box (200-1000ml),

PrePak bag (100-1000ml), Flexible BIB bag (2-220L).

FEATURES AT A GLANCE

1. MILK COLLECTION SYSTEM

2. MILK STANDARD SYSTEM

3. MILK UHT STERILIZER

4. ASEPTIC FILLER

The plant could flexible for UHT milk, pasteurizer, yoghurt, cream etc dairy product, capacity range from 500l/h-10,000L/h as per site need.

ASEPTIC FILLER

MILK STERILIZER

HOMOGENIZE

Company Profile

Shanghai Genyond Technology Co., Ltd.

Shanghai Genyond Technology Co., Ltd. is a manufacturer of extracting unit and fruit & vegetable processing line with well-equipped testing facilities and strong technical force.With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in food and beverage and other industries.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

View more

>>

Outdoor Decking, Composite Decking, Flooring, Bamboo and Plastic

>>

Jwz-Bm 15L Chemical Packaging Jerrycan Blow Molding Machine

>>

New model modern plastic waterproof apartment kitchen cabinet

>>

H20series Industrial Iot M2m 3G UMTS WCDMA HSPA IP Modem with RS232/RS485

>>

MMA Series AC ARC Welder BX1 180B welding machine circuit board

>>

618h Precision Grinding Machine Universal Surface Grinding Machine Saddle Moving Surface Grinding Machine

>>

Model Hammer Carbon Steel Head 8oz/16oz/20oz/24oz Hammer Factory Price

>>

Make PVC Material Dolls Figurine Custom Design Mini Vinyl Toy Action Figure PVC Toys for Decoration

>>

Silicone Foldable 8 Digits Calculator

>>

HC-S411 Endodontic treatment steps model Medical science endodontic model dental pulp disease clinical teeth teaching model

>>

2025 Kndmax Ws40 New Designed 35t 600 mm Diameter Used Firewood Processor Sale Log Splitter Hydraulic Firewood Processor

>>

1200f High Temperature Powder Coatings

>>

women popular plain t shirt

>>

USA Europe Market Car TPMS Diagnostic Scanner Programming Tool

>>

Carbide Dies and Punches, Automotive, Precision, Auto, Stamping, Car Mold Parts

>>

High Quality Timing Chain Kit TK1439 for TOYOTA with OE No.1350647020;1354047030

>>

3.5 Ton Mini Excavator Digger 3 Ton Hydraulic Bagger Machine with EPA/CE/Euro

>>

Mk2120+B+Atc Internal Hole and Internal Cone Hole Grinding Machine

>>

Water Jet Cutting Machine with Direct Drive Pump DDP-30

>>

Sunpal Flexible Bifacial Solar Panels 300W 450W 500W All Black N Type Solar Panel