US$10,500.00

10-14 Pieces

US$10,000.00

15-29 Pieces

Basic Info.

Type

Knee-and-Column Milling Machine

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Certification

CE, RoHS, ISO 9001

Max. Load of Table

600kgs

Longitudinal Travel (Manual/Auto)

900/880mm

Transverse Travel(Manual/Auto)

315/300mm

Vertical Travel (Manual/Auto)

380/360mm

Spindle Speed Range

30-1500rpm

Transport Package

Plywood Case

Product Description

Product Description

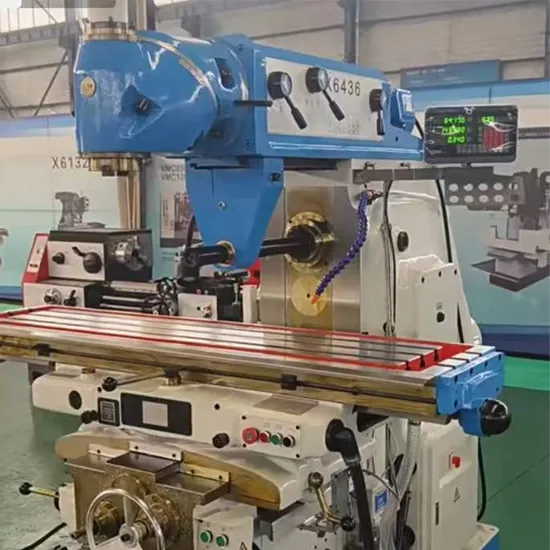

X6240 Universal Rotary Head Milling Machine

The universal rotary head milling machine has good rigidity and good precision retention. The spindle drive and feed drive both use an 18-level gear speed change, which has a wide speed change range. The universal rotary head milling machine has a wide processing range. In addition to being used as a vertical milling head, it can also rotate 360 degrees in two directions and is equipped with a spindle sleeve that can be retracted and can process bevels and holes at any angle.

The spindle taper hole of this machine tool can be directly or through accessories to install various cylindrical milling cutters, forming milling cutters, end milling cutters, angle milling cutters and other tools. It is suitable for processing planes, bevels, grooves, holes, etc., of various parts and components. It is an ideal processing equipment for machinery manufacturing, molds, instruments, meters, automobiles, motorcycles and other industries.

The two-section spindle head design can easily realize the vertical and horizontal milling conversion and the combination of any angle in space, and the rigidity is greatly improved compared to the three-section head. The two-section head is equipped with precise positioning pins to ensure the precise positioning of the vertical and horizontal milling conversion, which is more convenient to operate.

Machine Feature

The worktable and guide rails are ultrasonically quenched, and the worktable can rotate 45° left and right;

It can realize vertical and horizontal milling functions; the vertical milling head can rotate 360°;

The two-section rotary milling head and the spindle can rotate and adjust at any angle;

It can be used to process shells and molds;

The worktable X, Y, and Z are all gear-driven automatic feed;

The maximum stroke in the X direction can reach 900mm, with a large processing range.

Optional 320 diameter milling cutter disc for strong milling.

Product Parameters

| No. | Specifications | Units | X6240 |

| 1 | Table size | mm | 1700*400 |

| 2 | T-type slot numbers / width /space | mm | 3-18-90 |

| 3 | Max. load of table | kg | 600 |

| 4 | Longitudinal travel (manual/auto) | mm | 900/880 |

| 5 | Transverse travel(manual/auto) | mm | 315/300 |

| 6 | Vertical travel (manual/auto) | mm | 380/360 |

| 7 | Cutting feed speed | mm/min | X.Y: 23.5-1180. Z:8-394 |

| 8 | Spindle taper | | ISO40(V), ISO50(H) |

| 9 | Rapid feed speed | mm/min | X:2300.Y:2300 .Z:770 |

| 10 | Distance from table center to column guide way | mm | 215-470 |

| 11 | Distance from spindle axis to table surface | mm | 30-350 |

| 12 | Max. swivel angle of table | | ±45° |

| 13 | Spindle speed step | steps | 18 |

| 14 | Spindle speed range | rpm | 30-1500 |

| 15 | Spindle motor power | KW | 11 |

| 16 | Overall dimensions | mm | 2556×2159×1800 |

| 17 | Machine weight | Kg | 3850 |

After Sales Service

1. The Operation Manual will be sent with the machine.

2. The spare parts will be provided free of charge during the warranty period.

3. The 24-hour online Service Team will help you solve the problems that you meet!

4. We also provide after-service with video calls, videos, phone calls, online meetings, etc., to ensure you can use the machine better.

FAQ

1: How can I choose the most suitable machines?A: Please tell me your specifications. We can choose the best model for you, or you can select the exact model. You can also send us the product drawing, and we will select the most suitable machines for you.2: What about the quality of the machine? And after-sales service?A: Our machine warranty period is 1-2 years, and we provide free technical service.3: What are your trade terms?A: EXW, FCA, FOB, CFR, CIF, DDP, etc. are all acceptable.4: What are the Payment Terms?A: T/T, 30% initial payment when ordering, 70% balance payment before shipment;5: What's the MOQ?A: 1 set

>>

Environmental Fine Stone Rock Impact Hammers Crusher Price

>>

1800kN TPE Injection Molding Machine

>>

Fodder Chopper Grass Cutter Chaff Cutter Silage Forage Crushing Machine Hay Cutter

>>

380V Auto Compensation Device Disk Type Multi-Station Auto Cover Polisher

>>

Hot Sale Made in China Molding Automatic Block Brick Making Machine QS1000

>>

OEM Customized Other Riha Offer Shock Absorber Mould Plastic Injection Molding Barrel

>>

High Quality Car Accessories New GTR Type Front Bumper Grille for CLA Class W117

>>

High Quality Lock Nut Jack Equipment

>>

Byloo 4.8.1 18 1bb steel jigging fishing reel left right handle black spinning fishing reel

>>

Custom Steel Slotted Set Screws use for Mechanical Terminal Lugs

>>

China Wenovus Wngs-120 Multi-Functional Agricultural Machinery Gasoline Powered Reaper Farm Machine

>>

3D Lenticular Tech Training

>>

Galvanized Sheet Round Type Feeding Pipe for Poultry

>>

Vertical Gas Bain Marie with Cabinet for Catering Equipment

>>

Stainless steel rolled paper bar vertical round head without punching kitchen bathroom toilet paper rack European-style paper towel rack

>>

China Factory Glorystar Brand Nc Carbon Steel Bender

>>

Bicycle Parts 600d Bike Hand Bag (HBG-055)

>>

Semi Automatic Stitch for Carton Machine Packaging Machine

>>

Tadm3635 High Quality CNC Drilling Machine for Angle Bars

>>

crop stalk rope making machine rice corn straw rope maker