Product Details

Product Description

Product Description

OEM Plastic&Rubber Factory

Overview

Product Description

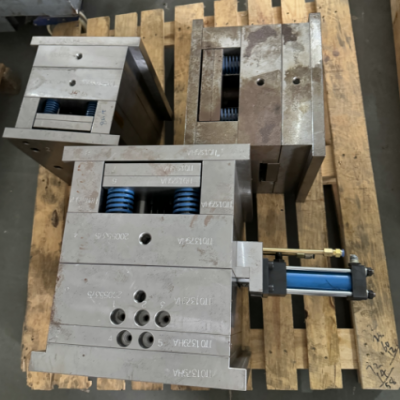

PLASTIC INJECTION MOLDING

Item

| Production products Customized plastic parts injection molding wholesale plastic parts mold plastic products

|

Material

| ABS, PC/ABS, PP, PC, POM(Acetal/Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), PMMA(Acrylic), SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE(Teflon), GPPS, PPS, PPO, PES, CA, etc.

|

Certificate

| IATF 16949:2016 / ISO 9001:2015

|

Drawing Format

| .stp / .step / .igs /.stl /.dwg / .pdf

|

Parameters

| Inch, centimeter, millimeter, etc.

|

Surface Treatment

| Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc.

|

Mold Material

| S136H, 718H, NAK80, P20, H13, etc.

|

Mold Life-cycle

| 100,000-500,000 shots.

|

Many kinds of raw material are frequently used, such as ABS, PC/ABS, PP, PC, POM, Nylon (PA6, PA66, PA12), PE, PS, PMMA(Acrylic), SAN/AS, ASA, PET, PVC, TPE, TPR, TPU, TPV. We can produce plastic products in some special materials, such as PBT, PEI (Ultem), PEEK, PSU, PPSU, PPE, PPE/PS, PTFE (Teflon), GPPS, PPS, PPO, PES, PPA, CA, DMC, PF, etc.

We can also add some additives according to the functional requirements of the project to improve the performance of the product, such as Reinforcing Agents, Flame Retardants, Fillers, Functional additives, Elastomer toughening agents, Weathering agents, Reflective agents, etc...

Our Customers

Material property

| Property | NBR | FKM | CR | EPDM | Silicone |

| Density | 1.5+0.1g/cm3 | 2.0+0.1g/cm3 | 1.5+0.1g/cm3 | 1.4+0.1g/cm3 | 1.25+0.1g/cm3 |

| Hardness | 30~90 (Shore A) | 30~90 (Shore A) | 30~90 (Shore A) | 30~90 (Shore A) | 30~90 (Shore A) |

| Tensile Strength | >=3.5MPa | >=8MPa | >=3.5MPa | >=5MPa | >=5.5MPa |

| Elongation at Break | >=280% | >=250% | >=280% | >=250% | >=300% |

| Compression Set | <=0.8% ( 70°Cx 22h) | <=0.7%(70°C x 22h ) | <=0.7%(70°C x 22h ) | <=0.7%(70°C x 22h ) | <=0.7%(70°C x 22h ) |

| Working Temp | -50 ºC -120ºC | -20ºC-200ºC | -40ºC-120ºC | -50ºC-150ºC | -55ºC-230ºC |

| Max.Pressure | 1.7MPa | 4MPa | 1.7MPa | 2MPa | 2MPa |

Our Company

Founded in 2002, Hyber is a professional manufacturer of molds, rubber, plastics and stamping hardware parts, and provides value-added services such as component assembly, screen printing, pad printing and ultrasonic welding. And obtained ISO 9001 and IATF16949 certificates earlier. We are committed to providing high-quality customized solutions for many industries such as automobile manufacturing, transportation, medical, industrial equipment, toys, etc.

With years of accumulated experience and technical strength, Hyber has become a well-known brand in the industry and has won the trust and support of customers around the world. Hyber company has always adhered to the concept of "excellence, continuous improvement", and is committed to becoming a benchmark enterprise in the industry.

In the future, we will continue to increase R&D investment, continuously improve our technical level, and provide better products and services to customers around the world. We look forward to working with more companies to jointly promote the development and progress of the industry. Welcome to visit the official website of Hyber Company to learn more about us and explore how we can help your business achieve greater success.

Products

Workshop

Packaging & Shipping

All custom parts will be well packed before shipping. They will be shipped by sea, by air or by express delivery according to the weight, the quantity or as the customers' requirements.

Our Service

Hyber provides on-stop service for plastic product customizing works. We provide mold design,precision plastic mold making,custom best quality plastic injection molding,Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

FAQ

1. Are you a trading company or a manufacturer?

We are a manufacturer as you can see our workshop as above.

2. What kind of trade terms can you do?

EX-WORKS,FOB,CIF,DDP DDU

3. What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy

of B/L. We accept T/T

4. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

5. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).

Contact Us

Tel

| +86-17856399864

|

Email

| sales02@hyber.cn.com

|

Web

| www.hyber.com.cn

|

>>

New Primary Color Folding Telescopic Rod Fishing Landing Net

>>

Customized 2mm-12mm Stepped Tempered Glass for LED Light

>>

Children′s Electric Car Four-Wheel Car Can Seat

>>

Galvanized Steel Tube Inspection/Size Check/Quality Assurance/Inspection Servicer

>>

Compact Two Roll Open Rubber Mixing Mill Manufacturer (xk-560) , Silicone Mixing Mill, Rubber Two Roll Mill, Compound Mixing Mill

>>

Brand New Automotive Parts 7 Series E66 Radiator Bracket Support Tie Bar 51717036326

>>

Fully Automatic Computerized Safety Valve Testing Platform

>>

Seto Face Plate Four-Bit Sc Fiber Optic Cable Broadband Socket Panel

>>

Rigid PVC Pipe Profile Board Plate Ceiling Trunking Crushed Scraps Pulverizer

>>

glow clear kayak, LED light transparent kayak, glow paddle, night tour crystal kayak, glow kayaking, night kayak

>>

Long Mileage SUV UHP AT/MT Budget Car Tyres/ PCR Tyres (205/55R16 195/65R15 185/65R15 175/70R13)

>>

High Security Bank Card Milling Machine

>>

Taijia modular ultrasonic flowmeter inline ultrasonic flow meter low flow tuf-2000m cheap ultrasonic flowmeter

>>

olive harvest machine

>>

Experienced Mirror Roller for Rubber Refining Mill Paper Leather Making Industry

>>

Stone Grinding Equipment

>>

Agate stone jade safety buckle internal and external mechanical type

>>

Vmc1580 CNC Machining Center/Good Quality Vmc CNC Milling Machine (TC-1580)

>>

Full Set Automatic Three-Bridge Stone Line Polishing Machine for Granite Marble Quartz Man Made Stone Grinding and Polish

>>

Digital Asphalt Bitumen Ductility Tester Asphalt Testing machine