Product Details

Product Description

Product Description

Product Description

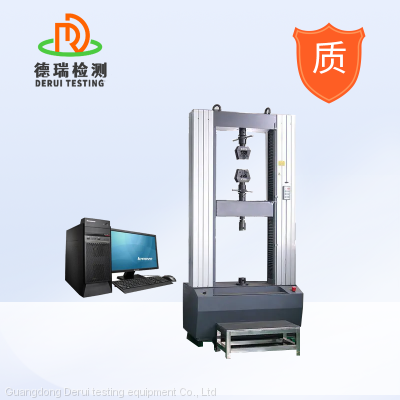

Computerized Double Column Tensile Testing Machine is used to test the mechanical properties of various materials such as static load, tensile, compression, bending,shearing, tearing, peeling and other mechanical properties of mechanical equipment. It is suitable for plastic plates, pipes, and other materials. Various physical and mechanical performance tests of profiles, plastic films and rubber, wires and cables, steel,fiberglass and other materials are developed for materials.

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection |

| Upper and lower limit switches |

| Load sensor with automatic retreat |

Applications

1. Tested sample: laminated materials, wood, leather, rubber & plastic, metal material, etc.

2. Different test with different grips: tensile, peel, tear, heat seal, adhesive, bend and open force.

3. Deformation under defined load: Test deformation under defined load of tested sample

4. Load under defined deformation: Test load under defined deformation of tested sample

Software can issue word/excel report with results for max. force, elongation, tensile strength, peel strength, tear strength,

compression strength, etc.

Tensile Strength Tester for Rubber Products

In the research and development, production and quality control of rubber products, accurate determination of tensile strength and other mechanical properties of rubber materials is an extremely critical step. Our rubber tensile strength tester is specially designed to optimize the characteristics of rubber materials, and with excellent performance, advanced technology and humanized operation experience, it has become a reliable tool for rubber industry practitioners.

I. Excellent testing performance to match the rubber characteristics

1. Accurate and sensitive force detection: The tester is equipped with a high sensitivity force transducer customized for rubber testing, with a force measurement accuracy of ±0.5% FS (full scale). Given the large elastic deformation range of rubber materials when subjected to force, this sensor can accurately capture the subtle changes in force from initial force to breakage, providing you with accurate and reliable tensile strength data. For example, when testing common natural rubber samples, key indicators such as yield point, maximum tensile force and breaking strength are clearly and accurately presented with minimal data error, providing a solid basis for rubber formulation optimization and product quality assessment.

2. Stable and high-resolution displacement monitoring: the use of high-precision displacement sensor, displacement measurement resolution as low as 0.001mm. rubber in the stretching process of large deformation and complex changes, the sensor can real-time, stable monitoring of rubber samples in the entire stretching process of the amount of deformation, to help you draw a very accurate stress - strain curve. This is of great significance to the in-depth study of the elastic behavior and plastic deformation characteristics of rubber materials at different stages of stress, as well as to the assessment of the durability and service life of rubber products.

3. Wide range and special loading mode: The tester is equipped with a wide range of force values, from as low as a few Nm to as high as thousands of Nm, which can fully meet the needs of testing rubber products with different specifications, hardnesses and applications. Whether it is an extremely thin rubber film or a thick rubber product, the tester can find the appropriate test range to ensure the accuracy and reliability of the test results. In addition, for the unique viscoelastic properties of rubber materials, the tester is also set up with special loading modes, such as slow loading to simulate the static force of rubber in actual use, or fast loading to test the dynamic mechanical properties of rubber, which provides comprehensive support for the performance evaluation of rubber products in different application scenarios.

Second, advanced technology to ensure accurate and efficient testing

1. High-performance drive and speed change system: the drive system combines AC servo motor and precision ball screw, which is smooth, low noise and high transmission efficiency. During the testing process, the loading speed can be precisely adjusted within a wide speed range of 0.001 - 500mm/min according to the rubber testing standards and actual needs, so as to realize uniform loading or variable speed loading. For example, in the implementation of GB/T 528 - 2009 “Determination of Tensile Stress and Strain Properties of Vulcanized Rubber or Thermoplastic Rubber”, it can be operated in strict accordance with the loading speed specified in the standard to ensure that the test results comply with the requirements of the standard and have good repeatability and comparability.

2. Intelligent automatic control system: Equipped with a powerful microcomputer control system, the whole testing process can be fully automated. You only need to enter the detailed specifications of the rubber sample, the selected test standard and the desired loading speed and other parameters on the operation interface, and the system will automatically complete all the processes from sample clamping, loading test to data acquisition and analysis, and display the test data and dynamic stress-strain curve on the screen in real time. In addition, the system also has perfect data storage, query and printing functions, which is convenient for you to effectively manage and analyze a large number of test results, providing strong support for the quality traceability and performance optimization of rubber products.

3. Professional data acquisition and analysis software: The data acquisition frequency is up to hundreds of times per second, which can quickly and accurately collect key data such as force value and displacement. At the same time, the built-in professional data processing software is deeply optimized for the characteristics of rubber materials, and can automatically calculate the important mechanical performance indexes of rubber materials, such as tensile strength, elongation, constant tensile stress, etc., according to the collected data, and generate detailed and standardized test reports. The format of the test report can be flexibly customized according to the user's needs to meet the diversified reporting requirements of different enterprises and organizations in the rubber industry.

>>

EV 940185PF EV1908 EV1908FP Auto Air Conditioning Evaporators 285x235x38 mm for Isuzu D-Max

>>

Metal Frame Making Machine C Z Purlin Profile Machine C/Z Purlin Roll Forming Machine for Sale

>>

Wholesale Applicable Front Blade Rubber Car Boneless Universal Wiper

>>

High Efficiency Single Phase Two-Value Capacitor Asynchronous Motor with Cast-Iron Housing

>>

Modern Marble & Metal Table Lamp with Fabric Shade Hotel Lamp

>>

carbon padel racket P07 plush shape factory wholesale

>>

Professional LCL/FCL Truck Shipping Freight Forwarder From China to Europe Germany UK France

>>

42.6mm White Golf Balls Golf Putting Practice Ball Standard Blank Customizable Logo Golf Accessories

>>

Welding Machine for Sale, Automatic Brazing Machine

>>

CNC High Speed Plate Drilling Punching Marking Machine FINCM Tower Fabrication Steel Plate High-Speed CNC Hydraulic Punching Drilling Machine

>>

Rubber PTFE Inner Material Electromagnetic Flowmeter for Pure Water

>>

High quality wholesale Regal LaCrosse Malibu XL Equinox Onix XT4 CT5 car Rear door upper hinge For Chevrolet Buick 13590932

>>

Forged Hammer Pattern Viking Stainless Steel Meat Cleaver Stainless Steel Butcher Knife set kitchen vegetable cutter

>>

PC, PMMA, GPPS, PET, MS transparent sheet production line

>>

3D Printer with Powder Bed Fusion for Metals

>>

Portable Handheld Metal Stainless Copper Laser Welder Metal Laser Welding Machine

>>

Zoomlion 36m Small Truck Mounted Concrete Pumps 36X-5z in Africa

>>

5W Intelligent Mini Fold-able Desktop Automatic Laser Engraving Cutting Machine

>>

2803050-Q367 Right Headlight Mounting Bracket D Assembly for FAW J6

>>

Exquisite electric waterproof and moisture-proof skylight