Product Description

Product Description

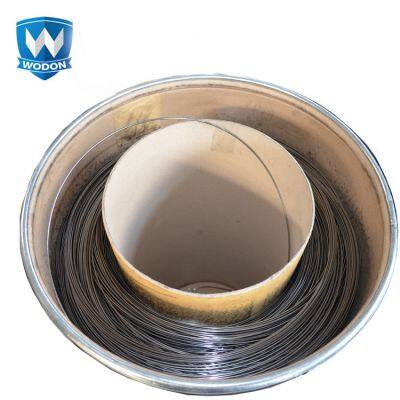

Product DescriptionWodon Factory hardfacing tungsten welding wireCharacteristics:1. A whole wire with no joint within one drum;2. Uniform wire diameter, smooth wire feeding;3. Stable arc, less spatter and smoke, no broken arc phenomena during welding;4. Hardfacing efficiency over 90%;5. Metallurgical bonding to base metal, uniform stress relief of after weld metal.Flux cored welding wireWe develop our wear resistant flux cored welding wires always according to working condition. This guarantee good performanceregarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency. The Filling rate of flux cored welding wire are about 50% with tolerance 1%, so that the chemical composition after welding are uniform and stable. We use advanced CNC system and regular test during the production, so guarantee the good welding result.Wodon hardfacing welding wire with super wear resistance1. Type: flux cored welding wire for hardfacing/surface welding/cladding2. Diameter: 1.2 mm, 1.6 mm, 4.0 mm, customized.3. Standard: GB4. Certification: ISO9001:2008, ISO14001:2004, OHSAA 18001-2007ModelDiameter[mm]Hardness[HRC]Main Ingredient[%]Main application and characteristicsD6881,2;1,650-58C: 2.5-5.0 Cr: 22.5-27.5Apply to a serious part of grinding wear surfacing, multi-layer welding. Surfacing layer thickness can be up 50 mmD7881,2;1,650-60C: 3.0-4.5 Cr: 24-30Apply to a serious part of grinding wear surfacing welding, welding layer thickness control under 20 mmD8881,2;1,658-65C: 3.5-4.5 Cr: 24-27.5Apply to a serious parts of abrasive wear surfacing welding, welding layer thickness control under 10 mmD788A1,2;1,650-60C: 3.0-4.5 Cr: 20-25Apply to a serious parts of abrasive wear surfacing, limited to single layer welding.D788M1,2;1,660-66C: 3.0-4.5 Cr: 24-30Apply to a serious parts of abrasive wear surfacingD688Welding Rod4.050-58C: 2.5-5.0 Cr: 22.5-27.5Suitable for severe abrasive wear parts hardfacing welding, surfacing layer thickness control under 20 mmGas Shelding Welding WireApplicationModelDiameter (mm)Hardness (HRC)Main IngredientHigh manganese steel hardfacing wire, Suitable for hardfacing hammer head, hammer plate and other high impact partsD1141.650-55C, Cr, MnSuitable for hardfacing bucket gear, mining machinery and other wear partsD1721.2, 1.6≥40C, Cr, MoSuitable for hardfacing the surface of wear parts, such as gear, digger. mining machinery and etc.D2121.2, 1.6≥45C, Cr, MoSuitable for hardfacing high manganese rail, bulldozer and other wear parts under impact.D2561.6HB≥170C, MnSuitable for hardfacing continuous casting rollD3131.645-50C, CrSuitable for repairing die and toughening tool, and mechanical parts with high wear performanceD3221.655-63C, W, MoSuitable for hardfacing hot rolling rollD4051.653-60C, Cr, Mo, W, VSuitable for hardfacing general corrosion resistant partsD4301.635-40C, CrSuitable for hardfacing valveD502Mo1.635-45C, Cr, MoSuitable for hardfacing continuous casting rollD5181.640-50C, Cr, Mo, NiSuitable for hardfacing heavy wear parts, multi-layer welding up to 50 mmD6881.2, 1.650-58C, CrSuitable for hardfacing heavy wear parts, multi-layer welding up to 20 mmD7881.2, 1.650-60C, CrSuitable for hardfacing heavy wear part, single layer welding onlyD788A1.2, 1.650-60C, CrSuitable for hardfacing heavy wear parts, multi-layer welding up to 10 mmD8881.2, 1.658-65C, CrSuitable for hardfacing heat resistant wear partsD9951.658-65C, Cr, Nb, W, VCement Squeeze Roller Welding WireApplicationModelDiameter (mm)Hardness (HRC)Main IngredientSuitable for base layerHB-JYG1#2.8-C, Cr, MoSuitable for buffer layerHB-JYG2#2.855-63C, Cr, MoSuitable for pattern layerHB-JYG3#2.855-63C, Cr, MoFlux cored welding wireModelSpec. (mm)Hardness (HRC)Main Ingredient (%)HB-YD1721.2, 1.6≥50C: 0.4-0.5 Cr: 1.5-2.5Mo: 1.5-2.5Main Application:Used for surfacing welding gear, mining machinery, such as wear and tear parts.Flux cored welding wireModelSpec. (mm)Hardness (HRC)Main Ingredient (%)HB-YD3131.645-50C: 0.2-0.3 Cr: 11-14Main Application:Used for continuous casting roller surfacing.Flux cored welding wireModelSpec. (mm)Hardness (HB)Main Ingredient (%)HB-YD2561.6≥170C: 0.5-1.1 Mn: 10-17Main Application:Used for all kinds crusher, high manganese steel rail, bulldozers and other easy wear welding parts.Wodon hammerhead and hammer plate hardfacing welding wire with wear and impact resistanceModelSpece.(mm)Hardness(HRC)Main Ingredient(%)Application and characteristicsWD-D1141.650~55C: 0.45~1Cr: 2~3Mn: 14~18High manganese steel surfacing welding wire, after violent shocks has the surface the characteristics of the strain hardening,suitable for welding such as impact hammerhead, hammer plate partsOur company develop our own WD-series welding wire, which is self gas shielding welding wire. When you use our welding wire don't need shutz gas. After using of our WD-D114 high manganese surfacing welding wire to surfacing impact hammerhead and hammer plate have very good Impact resistance because of High chemical composite from flux core.Wodon high standard wear resistant flux cored mig welding wire for hardfacing rollerMig welding wire We develop our wear resistant flux core welding wires always according to working condition. This guarantee good performance regarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency.ModelSpec.(mm)Hardness(HRC)Main IngredientApplication and CharacteristicsWD-D4302.4, 3.235~40C: 0.1~0.25 Cr: 16~18Used for general corrosion-resistant components surface weldingWD-D320H3.2, 4.0---C: 0.1~0.25 Cr: 12~14Suitable for continuous casting roll surface weldingWD-2243.2, 4.045~55C: 0.25~0.35 Cr: 5.5~7.5Mo: 0.8~1.5 W: 1.0~2.0V: 0.5~1.0Suitable for hot-rolled billet roller surface weldingWD-224B3.2, 4.053~60C: 0.25~0.55 Cr: 5.5~7.5Mo: 0.8~1.5 W: 1.0~2.0V: 0.5~1.0Suitable for hot-rolled billet roller surface weldingWD-414N3.2, 4.040~50C: 0.05~0.15Cr: 11.5~14.5 Mo: 0.5~1.5Suitable for continuous casting roll suface weldingWD-414-03.2, 4.040~50C: 0.05~0.15Cr: 11.5~14.5 Mo: 0.5~1.5Suitable for continuous casting roll surface weldingWODON manufactured wear resistant hardfacing wire for vertical millVertical Mill use wear resistant welding wire to repair Our company is also specialized in manufacturing Vertical Mill welding wires (WD series). These serie's models have excellent welding performance and present great welding forming and low welding spatter. We can guarantee high Hardness and abrasion resistance after repairing, resulting in a service life no less than 8000 hours. We have a special team, who have a extrem experience in repairing the Vertical Mill and targeted special selection of repairing welding wires from our WD Series.ModelSpec.(mm)Hardness(HRC)Main IngredientApplication and CharacteristicsWD1002.4, 2.8, 3.255~62C: 3.0~5.0 Cr: 25~30Mo: 0.5~1.0Used for repairing grinding coal mill roller of thermal power plant.WD100A2.4, 2.8, 3.257~62C: 3.0~5.0 Cr: 27~32Mo: 0.5~1.0Used for repairing cement roller mill of raw material, clinker and slag.WD3502.4, 2.8, 3.255~62C: 3.0~5.0 Cr: 22~28Mo: 0.3~1.0 Nb: 3.0~4.5Used for repairing cement roller mill of raw material, clinker and slag.WD350A2.4, 2.8, 3.257~62C: 3.0~5.0 Cr: 22~28Mo: 0.3~1.0 Nb: 3.0~4.5Used for repairing cement roller mill of raw material, clinker and slag.WD6502.4, 2.8, 3.255~63C: 3.0~5.0 Cr: 22~28Mo: 0.3~1.0 Nb: 6.0~7.5Used for repairing cement roller mill of raw material, clinker and slag.WD650A2.4, 2.8, 3.257~63C: 3.0~5.0 Cr: 20~26Mo: 0.3~1.0 Nb: 6.0~7.5Used for repairing cement roller mill of raw material, clinker and slag.SpecificationWodon welding wire advantages. 1. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.2. welding wire without any joints, vacuum packing into carton,Quality warranty period longer than one year.3. Production Capacity: 9000 tons per year4. Short Delivery Time: Generally 7 days5. We have many experienced professionals to research and develop welding wires according to customers' specified chemicalcompositions.6. We can recommend proper welding wires and provide technical solutions based on working conditions.7. on site inspection and third party inspection are available.8. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.After-sales commitmentOur company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.Quality ControlWe have our own inspection technology department. The team are made of many experienced technical with material science bachelor degree and the team leader are with master degree. They are very professional to inspect and run test on the products. According to our company's policy each our product have a special number, so we can trace back to anywhere, if there are quality problems.We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.General Description:Characteristics:1. A whole wire with no joint within one drum;2. Uniform wire diameter, smooth wire feeding;3. Stable arc, less spatter and smoke, no broken arc phenomena during welding;4. Hardfacing efficiency over 90%;5. Metallurgical bonding to base metal, uniform stress relief of after weld metal.Wodon flux cored gas shielding surface welding gear welding wire We developed our own flux cored welding wire with customized ingredient for all kinds of working conditions. Our welding wires has following advantages:1. smooth wire feeding, stable arc , uniform diameter2. less patter and smoke during welding, above 90% hardfacing efficiency3. every drum packed with one whole PC of welding wires, without any joint, no broken arc phenomena during the welding to improve production efficiency4. developing more than 100 kinds of flux cored wear resistant requirements of many wear resistant field which can satify the wear resistant requirements of many wear resistant parts under all kinds of working conditions.5. the base metal and the wear resistant overlay are metallurgical bonding; after welding, the wear resistant layer doesn't fall off because of uniform stress relief.We can provide qualification certificate, product data sheet, test report including chemical compostion, hardness, etc of wear resistant overlay.ModelSpec. (mm)Hardness(HRC)Main Ingredient(%)Application and CharacteristicsWD-ZYG100(1#)1.6, 2.8, 4.0--C: 0.03~0.15Mn: 0.5~2.5Used in squeeze roller backing weldingWD-ZYG100(1996)1.6, 2.8, 4.0--C: 0.05~0.15Cr: 18~22Ni: 8~11 Mn: 4~7Used in squeeze roller backing weldingWD-ZYG2001.6, 2.8, 4.020~35C: 3.5~4.6 Cr: 4.0~6.0Mo: 0.3~1.0Nb: 0.3~1.0Used for welding transition layer of extrusion rollerWD-ZYG3001.6, 2.8, 4.050~55C: 0.3~1 Cr: 5~10Mo: 0.5~1.5 Nb: 1~3Used for welding transition layer of extrusion rollerWD-ZYG5001.655~60C: 0.5~2.5 Cr: 5~10Mo: 0.5~1.5 Nb: 3~6Used in welding extrusion roller surface and pattern layerHow to product flux cored welding wires?After cutting and joining into the steel strip with our fixed width, the roller squeezes our steel strip into "U Type" form and filled up with flux powder with our own special ingredient. The primary flux cored welding wire are continuously to stretch through the different diameter of the abrasive tool. After that, our flux cored welding wires are going to be packeted without a joint into Drum or Spool with waterpoof and desiccant. During the process and after process we have strickly inspection policy about the filling rate, bending rate, chemical composition and welding perform etc.1. Cutting steel stripOur steel belt is purchased from China's large steel belt factory. We will test the thickness and stretchability of the steel strip. And cutting the steel belt into 9 segments,then connect these steel belt by steel band butt welder, no broken ends. 2. Cleaning steel stripGet into the ultrasonic cleaning machine for cleaning the steel strip, and then drying,no water stains on the steel strip. 3. Filling into powder of flux cored welding wiresFirstly, the steel strip is extruded into a U-shaped through the machine,then filling the powder into the steel strip. We have more than 100 kinds of flux cored welding wire, according to the specific purpose to recommend the most suitable flux cored welding wire model. And we can also specialize in the development of customer needs flux cored welding wire. R & D of flux cored welding wire allows customers to test. 4. Drawing formingOur flux cored welding wire's standard diameter have 1.2mm; 1.6mm; 2.4mm; 2.8mm; 3.2mm; 4.0mm. And we have the CNC machine to control the powder flow, the fluency of welding wires feeding and the diameter. The system of this CNC machine is debugged by our own technical staff, can ensure good wire production efficiency. 5. Packing and finished product's inspectionThe packing sizes of our welding wire are 150-250kg/barrel and 15kg/box. Our packing barrels are waterproof, and 4 packets of desiccant are placed in each barrel. In order to protect the wire, it is not easy to damp. Each barrel (package) welding wire is a whole welding wire, without joint. The welding process has no arcing phenomenon andimproves production efficiency. As well as, our quality control personnel will check whether the finished welding wire is qualified every day.Wodon manufactured Tungsten carbide flux cored welding wire for die and toughOur company developed special tungsten carbide flux cored welding wires are with super good wear resistance and good impact resistance, which are suitable for wear parts with heavy wear like die and tough. After welding garantee a hardness 55-63 HRC or 600-780 HV, no need for shutz gas,no cleaning slag, low welding spatter, smooth surface, high welding efficiency.ModelDiameter[mm]Carbon[%]Tungsten[%]Molybdenum[%]D3221.60.3-0.57-100.5-2.5Hardness [HRC]55~6355~63ApplicationSuitable for repairing die and tough, and require a higher wear properties of mechanical parts.Suitable for repairing die and tough, and require a higher wear properties of mechanical parts.Wodon wear resistant flux cored welding wire for hardfacing steel factory hot roller1. Type: flux cored welding wire for hardfacing.2. Diameter: 1.6 mm, 3.2 mm, 4.0 mm, customized.3. Standard: GB4. Certification: ISO9001:2008, ISO14001:2004, OHSAA 18001-2007ModelDiameter[mm]Hardness[HRC]Main Ingredient[%]ApplicationWD2243.2;4.045-55C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance.WD224B3.2;4.053-60C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance.WD4051.658-65C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance.WarehouseIn our Warehouse are strictly managed, so our raw material and our products always good protected and are able to transport quickly and efficient.1,Portable SpectrumWe run regular test on our products according to company's policy based on ISO9001:20082, Rockwell Hardness testerWe are welding the welding wire on our experiment table, and cutting into small samples, so we can test the hardness and chemical composition.3,Welding wire experiment table In our labor can those small samples betested seriously like Hardness chemicalcomposition,weldingperformance etc.4,FactoryOur Factory have 2000 square meters for Office and total 4300 square meters for office, workshop and warehouse. Now we are building a new branch factory in Jiangsu to improve our production capacity.5,WorkshopWe have 3 workshops and total 36000 square meters, after the new branch finished will be one more big workshop to production. In June 2017 operation the new factory all function to production.6,WarehouseWe have two warehouses and totally area 5000 square meters. Our logistic department are in charge of the distribution our products, so that our client can have the goods in shot time.Wodon wear plates are used to make many complex wear parts to be positioned in high wear places. We have several equipments to transform our plates: six sets of plasma cutting machines, four bending machines and pressing machines, with high processing capacity operated by engineers and technical experts. We can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings. Our products can be processed into different kinds of wear parts used in kinds of fields.1. screen plate/vibrating plate2. proetection cover3. bolt embedded in the back4. round to square transition5. bend6. troughWelding wire for hardfacing coal scraper conveyorCentral groove after using high hardness flux core wire We develop our wear resistant flux cored welding wires always according to working condition. This guarantee good performance regarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency. We can guarantee high hardness and abrasion resistance after repairing, resulting in a service life no less than 8000 hours.ModelSpec.(mm)Hardness(HRC)Main IngredientApplication and CharacteristicsZBS-100(D212)1.2, 1.6≥50C: 0.4~0.7Cr: 4.0~5.5Mo: 0.8~1.5Used for surface welding, the surfaces of all wear parts, such as gears, bucket, mining, machinery etc.ZBS-200(D688)1.2, 1.645~55C: 2.5~5.0Cr: 22.5~27.5Apply to a serious part of abrasive wear surface multi-layer welding. Surfacing layer thickness can be up to 50 mm.ZBS-300(D888)1.2, 1.658~65C: 3.5~4.5Cr: 24~27.5Apply to a serious part of abrasive wear surface welding, welding layer thickness control under 10 mm.We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy. In our Laboratory there are the Rockwell Hardness tester to test the Hardness of the small welding samples, the portable Spectrum to test the chemical compostion easily at the work pieces on the scene, the portable Hardness tester to test the Hardness easily at the work pieces on the scene and the portable ultrasonic thickness measurement instrument to test the thickness easily and accurate. There are also abrasion resistance testing machine and a series of metallograhy experiment instruments, so the metallurgical microstructure and wear resistance can be tested. The below picture shows our laboratory. There are many equipments to suppert our Quality Inspection Technology Department, for sample: a series of metallographic analysis equipments, protable spectrum, protable ultrasonic thickness tester, protable ultrasonic hardness tester, destop Rockwell hardness tester, Infrared carbon sulfur analyzer, Quartz sand rubber wheel abrasion test machine and Reciprocating abrasion tester.We are certified with the ISO9001:2008 and keep continuously improving our quality management system. We have strict procedures for raw materials, products inspection, production process, storage management and after sales service.We are certified with the ISO1400:2004 and keep continuously improving our environmental management system. We use the electric boiler not the coal fired boiler to protect the environmental. We use the advanced dust removal and ventilation equipment to keep the air clean. We are certified with the OHSAS18001-2007 and keep continuously improving our occupational health and safety management system.Our every technical staff wears filter mask, protective clothing and gloves and welding goggles.Packing & DeliveryPackaging: 15 kg/spool, vacuum packing into carton, Steel Pallet, Plastic film, Customized.Packing Size: 1.15 m*0.58 m*0.88 m, 1.15 m*1.15 m*0.88 m, customized.Delivery Detail: Generally 7 days, if the goods are in stock. or it is 10~15 days if the goods are not in stock, it is according to quantity.Shipment: Loading into 20 ft or 40 ft Container.We packet our flux cored welding wire in different weight according to the Diameter. Welding wires of the Diameter 1.2 mm and 1.6 mm are 15 kg/spool, without joint vacuum packed into carton. Welding wire of the Diameter 2.8 mm, 3.2 mm and 4.0 mm are 50 kg/spool or 150~250 kg/drum without joint with Desiccant waterproof packed. So our flux cored welding wire can stand effect with in 6~12 mouth, if the goods are stored properly.Company ProfileJiangsu Wodon Wear Resistant Material Co., Ltd (CHINA WODON) is a company which is specialized in researching and developing wear resistant material. The company was founded in 2014. Now we have more than 300 employees, including more than 15 R&D staffs. Our company's registered capital is 30,000,000 CNY, with an annual output of 9,000 tons welding wire and 200,000 square meters wear plate. With numerous experienced technicians and excellent engineers, our product quality has improved constantly. Since company established, we are adhering to professional development road and win the market with the leading technological level, the excellent product quality and the integrative service concepts. We keep a long-term cooperation with Beijing University Of Technology, Iron And Steel Research Institute, Beijing Electric Power Equipment Research Institute, etc. Jiangsu Wodon main products: wear plates, wear plate welding wires, coal grinding roller welding wires, vertical cement mill welding wires, squeezeroller welding wires, roller welding wires, etc. We have independent intellectual property right, multiple patents, professional team for researching and debugging, providing one-stop services for customers. Jiangsu Wodon poducts are widely used in many industries, for example: power, iron and steel, cement, glass, mining, coal processing, metallurgical machinery, engineering machinery, loading machinery, port transportation, etc. Wear resistant plate is far ahead of other similar products on the market in many ways, such as chemical composition, microstructure, hardness, wear resistance performance, flatness, etc. Our wear plate can greatly extend maintenance time, thereby reducing maintenance cost in the practical application. Jiangsu Wodon persist to the principle of responsibility, profession, openness and sharing. Exploring business innovation, strengthening persionne development, improving management structure and optimizing operating mechanism. The company implements humanized management,provides study opportunites, continuously improves welfare and work environment. To the pursuit of perfect quality and customer satisfaction, we have certified with ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system. We sincerely provide high quality wear resistant products and services to customers. We will always supply our best products, adhere to quality first and keep up the spirit of striving for perfection.We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardface wear plate. These can overcome the problems like: low productivity, poor flatness and overlay falling off etc. This is a high automation level machine, each welding gun can operate independently and restart exactly from the point it had stopped, simplifying the operation process.FAQJiangsu Wodon Wear Resistant Material Co., Ltd. (China Wodon) is headquartered in Jiangsu, a port hub city in North China. There are over 300 staffs, including 30 experienced R&D engineers. Our main products include: Chromium carbide overlay (CCO) wear plates, Flux cored hardfacing welding wires etc.With independent intellectual property rights and a number of patents, we have a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the leadin providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.4 Major production bases: Jiangsu, Hebei, Hunan, Jiangsu. 68 Wear plate production lines (over 130 welding torches). 5 Welding wire production lines.Annual output of chromium carbide wear plates: 200,000 square metersAnnual output of flux cored hardfacing wires: 9000 tons.Q: Are you trading company or manufacturer ?A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.Q: How long is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according toquantity.Q: Do you provide samples ? is it free or extra ?A: Yes, we could offer the sample for free charge.Q: What is your terms of payment ?A:30% T/T in advance ,balance against copy of BL. also, FOB, CIF, CFR all are available for your product.Q:who are we?A:We are based in Jiangsu, China, start from 2014,sell to Domestic Market,Oceania,North America,SouthAmerica,Africa,Eastern Europe,Central America,Southeast Asia,South Asia. There are total about 301-500 people in our office.Q:how can we guarantee quality?A:Always a pre-production sample before mass production;Always final Inspection before shipment.Q:what can you buy from us?A:Chromium Carbide Overlay Plate,Wear Plate Liner,Flux Cored Welding WireQ:why should you buy from us not from other suppliers?A:The chromium content as high as 25~50% in the overlay The chromium carbide (Cr7C3) volume fraction above 50% Uniform distribution and high hardness HRC 58~65 Smooth surface, thickness tolerance +0~+0.5 mm only Flatness tolerance -3~+3 mm/mQ: what services can we provide?A:Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;Accepted Payment Currency:USD,AUD,CNY;Accepted Payment Type: T/T,L/C,Cash;Language Spoken:English,Chinese,Spanish,Portuguese,GermanIf you have another question, pls feel free to contact us as below:

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd.

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company's technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

View more

>>

Grinding Mill Price Stone Mill Grind Machine Limestone Powder Making Machine Raymond Mill with Dryer for Diabase Powder

>>

Greetmed High quality hospital adjustable electric bed

>>

Water Proof Disposable Plastic Pp Cpe Medical Boot Shoe Covers Disposable Non Slip

>>

Windproof Sunshade Slats Aluminum Shutter Window

>>

Vacuum Sealer Machine Food Meat Fruit Vegetable Vacuum Packing Paper Packaging Material

>>

High Voltage Power Line Lightning Protection Suspension Type 10kv Polymer Insulator

>>

For AUDI Auto Engine Timing Chain Tensioner Car Engine 06E109217A 06E109217H TN1505-2

>>

2021 Shangtao The New Yarn Guide Textile Ceramic

>>

Colorful children indoor plastic slide and swing playground toys equipment for sale

>>

Interior Decoration Aluminum Expanded Metal Mesh for Ceiling Tiles

>>

Pet Dog Cat Car Seat Belt Dog Accessories Adjustable Harness Lead Leash Small Medium Travel Clip Puppy Collar Leash

>>

beer brewing equipment for beer brewery and micro brewery

>>

Sany Sy390h Sy415h Sy500h Sy650h Sy750h Large Mining Excavators

>>

Pupolar Type Nitrile Microfoam Glove Equipment

>>

Factory Direct Sale 6n40A Automatic Multi-Functional Rice Husking Machine Food Machine

>>

Wholesale N2o Gas Nitrous Oxide Food Grade 615g 2100g 3.3L Whipped Cream Charger Nitrous Oxide Gas Cylinders Fast Gas N2o Cream Chargers

>>

8-cavity sports water bottle plastic cap mold

>>

Cashino KMP-III Mini Bluetooth Thermal Printer 80mm Portable Ticket Printer for Business Trips with Micro USB WiFi Interface

>>

Bioland Factory Outlet Conical Sterile PP Centrifuge Tubes 50ml Sterile Test Tubes Clear Bulk

>>

6012000314 Sprinter Shock Absorber Vibration Damper for Mercedes