|

US$140,000.00-700,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Material Processed

Rubber

Computerized

Computerized

Certification

ISO9001:2008, CE

Gear Box Cooling

by Water

Safety Design

with PLC Auto Control

Transport Package

Film with Wooden Pallet

Product Description

Product Description

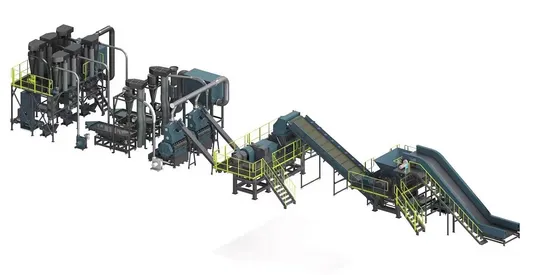

The Waste Tire Recycling Line can handle the used tires. It recycles rubber, steel wire, and fiber from tires using a room temperature treatment process.

It consists of a tire crusher, steel wire separator, disc sorting system, rubber crusher, miller, fiber sorting system, magnetic separator, screening equipment, dust collection system, cooling system, and automatic control system.We can tailor the solution to your specific needs. Capacity ranges from 1-20ton/hr. Rubber products are 8-200 mesh.

Working Process

1. Evenly convey tires into the double-shaft Shaft Shredder.

2. The shredder can handle tire shreds as small as 80mm.

3. Tyre shreds larger than 80mm are returned to the shredder via the back feeding system.

4. Tyre shreds smaller than 80mm will be sent to the Rasper, where they will be crushed into materials smaller than 18mm. They will be filtered, yielding a mixture of rubber chips and waste steel wire.

5. It will separate the steel wire from the mixture using a magnet separator. The rubber chips will be crushed by a rubber granulator.

6. High-speed rotors crush the rubber chips into 1-6mm rubber granules.

7. Different sizes of rubber granules and rubber powder will be separated.

8. The Miller will grind rubber granules into 20-80 mesh rubber powder.

9. It includes a dust collection system for dust, powder, and waste fiber.

10. The entire line is automated. It's secure, stable, and dependable.

Detailed Photos

Product Parameters

A tire shredder can shred scrap tires (small car tires, half wire tires, full wire tires, engineering tires, etc.) into 20-200mm rubber blocks, the size of the rubber block can be adjusted to your requirements. There are two ways to feed material--using a conveyor or the grabbing machine. The large volume tires can also be configured with a tire feeding pressure system to improve production efficiency.

The tire rasper is mainly used for scrap tire processing, the size of the rubber block should be below 60mm. The rotor knives cut the rubber and steel wire away from the machine through medium-speed rotation. Then we get the wire mixture of the rubber and waste steel below 12mm. With the subsequent processing process,we can sort out rubber from waste steel wire.

The rubber crusher can crush the rubber block into rubber particles below 6mm by rotating at high speed.

Certifications

>>

Factory Direct Manual Lathe Milling Chuck Machine Tool with 750mm, Semi-Automatic Lathes.

>>

SS316 Socket Head Bolt ISO7380 Hex Socket Head Machine Screw/SS304 Button Head Socket Cap Screw

>>

Tree planting digging machines / ground hole drill / earth auger portable ground drill

>>

Toyo-Intl Ocs-B Type 0.5 Ton-50 Ton Digital Crane Scale

>>

REX521GHHPSH07G ABB module supply

>>

Diameter 10mm Diamond Wires Saw for Marble/Limestone

>>

Warehouse Flared Welded Galvanized Steel Metal Storage Wire Mesh Decking for Pallet Racking

>>

Hot Sales All Purpose Customized Colors Spray High Application Good Coverage OEM Acrylic Spray Paint

>>

Farm Mechinery Mini Diesel Motocultor Power Tiller Two Wheel Mini Walking Hand Tractor Foragriculture

>>

Multifunctional Kitchen 800 Waste Shredder/Organic Waste Shredder/Food Waste Shredding Machinec/Crusher Machine

>>

Stainless Steel Food Grade High Power Dispersing Mixer Emulsifier for Honey

>>

60W/80W/100W CO2 Laser Engraving Cutter Machine for Acrylic Glass Wood

>>

High Precision CNC Lathe Machine Cak6150 Horizontal CNC Turning Lathe Machine

>>

new fashion 3 ply disposable face mask medical grade from direct factory

>>

Small Vertical Drilling Milling Machine for Sale Zxtm40 Zx50c Zx45 Zx32g Zx32g-1

>>

Clear Removable Reusable Washable Red Film Double Sided Adhesive Acrylic Foam Tape Nano Tape

>>

Htx340 Women Perfume Professional Manufacturer OEM Floral Perfumes

>>

15-in-1 Outdoor Camping Combination Pliers Survival Hatchet Multi Tool Axe Hammer

>>

Guaranteed Quality Unique Seed Germination Incubator

>>

Cw61125 Heavy Duty Horizontal Manual Lathe Digitalanzeige Drehbank Torna