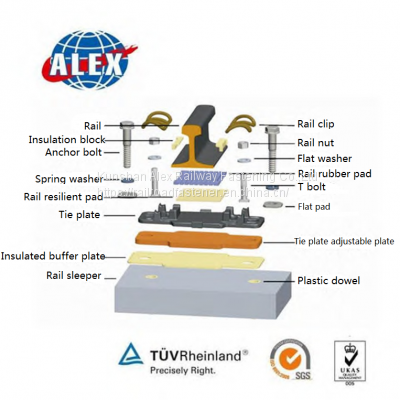

WJ-7 Fastener System Features:High flexibility, high insulation, strong versatility of the structure, high pressure attenuation of the elastic buckle and high fatigue strength, reliable connection with the foundation, high and low rail position and large adjustment of the left and right position are needed for the passenger-only line ballastless track fastener system.

Reduce the pressure attenuation of the spring buckle and improve its fatigue strength;

Improve the reliability of the T-bolt in the iron pad.

| Serial number | Name | Quantity | Material | Mass or volume | Remarks |

| 1 | T-bolt T1 | 2 | Q235-A | 0.76 kg |

|

| 2 | Nut M24 | 2 | Q235-A | 0.224 kg |

|

| 3 | Flat Washers | 2 | Q235-A | 0.138 kg |

|

| 4 | W1 type elastic bar | 2 | 60Si2MnA | 1.44 kg | Choose one according to the line resistance. |

| X2 type elastic bar | 1.22 kg |

| 5 | WJ7 insulation block | 2 | Glass fiber reinforced polyamide 66 | 72.6 cm3 |

|

| 6 | WJ7 iron pad | 1 | QT450-10 | 10.2 kg |

|

| 7 | WJ7 insulation cushion board | 1 | Rubber | 420 cm3 |

|

| 8 | WJ7-A rubber pad | 1 | rubber | 270 cm3 | The speed is 250km/h for passenger dedicated lines, and one of them is selected according to the specific requirements of line resistance. |

| WJ7-A composite pad | rubber | 270 cm3 |

| stainless steel | 0.24 kg |

| WJ7-B rubber pad | rubber | 325 cm3 | The speed is 350km/h for passenger dedicated lines, and one of them is selected according to the specific requirements of line resistance. |

| WJ7-B composite pad | rubber | 325 cm3 |

| stainless steel | 0.24 kg |

| 9 | Anchor bolt B1 | 2 | Q235-A | 2.20 kg |

|

| 10 | Heavy duty spring washer 30 | 2 | 65Mn, 60Si2Mn | 0.09 kg |

|

| 11 | WJ-7 flat pad | 2 | QT450-10 | 0.50 kg |

|

| 12 | Pre-embedded casing D2 | 2 | Glass fiber reinforced polyamide 66 | 200 cm3 |

|

| 13 | WJ7 rail heightening pad |

| Polyethylene | 27.7 cm3/mm | According to the specific situation |

| 14 | WJ7 iron pad down the high pad |

| Rubber | 310 cm3/5mm | According to the specific situation |

| Fastener type | WJ-7 fastener |

| Taxonomy | With iron pad (thickness 16mm) |

| Withstand lateral force | Mainly overcome by the friction under the iron pad |

| Connection with the foundation | Embedded plastic casing |

| Embedded member pull-out resistance | Not less than 100kN |

| Rail Clip | Types | W1 type | Type X2 |

| Buckle pressure | >9kN | 6kN |

| Strike | 14mm | 12mm |

| Fastening method | Bolt fastening |

| Tightening torque | About 120 Nm | About 80Nm |

| Rail longitudinal resistance | >9kN | 4 kN |

| Rail pad fastening torque | 300~350Nm |

| Elastic Rail Insulator | Setting | An elastic cushion layer (rubber pad or composite rubber pad) is arranged under the rail, and a cushion layer (insulation cushion pad) is arranged under the iron pad plate. |

| size | Class A | Class B |

| Under-rail rubber pad: 169×168×12 (composite thickness 13.2) | Rubber pad: 169 × 168 × 14 (composite thickness 15.2) |

| Insulation cushion plate: 486 × 204 × 5 |

| Under-arc cushion stiffness | 30~40kN/mm | 20~30kN/mm |

| Sub-layer cushion stiffness | >1000kN/mm |

| Rail height | High rail surface | Class A | Class B |

| 211 rubber pad 212.2 composite pad | 213 rubber pad 214.2 composite pad |

| Adjustment amount | 30mm |

| Adjustment method | The adjustment of 10mm and 20mm is achieved by inserting the heightening pad between the rail and the iron pad and between the iron pad and the foundation. The filling pad can be adjusted steplessly. |

| gauge | Adjustment amount | ±12mm |

| Adjustment method | This is achieved by moving an iron pad with a long round hole, without the need for spare parts. |

| Adjustment level | Continuous stepless adjustment |

| Rail joint treatment | General purpose |

| Applicable to ballastless track | No shoulder-free track structure |

| Drawing number and standard | Research Line 0603, Science and Technology Base [2007] 207 |

| Application condition | 250 km/h | 350 km/h passenger dedicated line |