|

US$44,500.00-55,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Metal

Guide Rail

Horizontal Guide Rail

Controlling Mode

Artificial

Precision

Normal Precision

Certification

GS, CE, ISO 9001

Pipe Threading Range

80-295mm

Max.Length of Work-Piece

1500mm

Maximum Machining Length

1250mm

Max Dia. Swing Over Bed

800mm

Max Dia. Swing Over Cross Slide

470mm

Transport Package

Iron Sheet Packaging

Production Capacity

1000/Year

Packaging & Delivery

Package Size

405.00cm * 185.00cm * 180.00cm

Package Gross Weight

7500.000kg

Product Description

Product Description

This series of pipe thread lathes is mainly used to process internal and external threads of pipes, and they can also be used as an ordinary lathe to process the outer circle, inner hole, and end face of shaft, pipe, and disk parts. This machine tool is widely used in the petroleum industry, which can process and repair parts such as drill pipes, joints, and casings. It is also used for the thread processing of various pipes and drill pipes in industries such as coal, chemical engineering, water conservancy, and geological exploration.

Product Parameters

| Item | UNIT | Q1330 |

| Max dia.swing over bed | mm | 800 |

| Max dia.swing over cross slide | mm | 470 |

| Max.length of work-piece | mm | 1500 |

| Maximum machining length | mm | 1250 |

| Pipe threading range | mm | φ80-295 |

| Width of bed | mm | 600/650 |

| Spindle bore | mm | 305 |

| Spindle center height | mm | 400 |

| Power of spindle motor | KW | 15 |

| Spindle speed | RPM | VF2 STEPS 20-100/100-300 |

| Z axis feed grade/range | Mm/r | 32/0.095-1.4 |

| X axis feed grade/range | Mm/r | 32/0.042-0.7 |

| Carriage rapid traverse speed | mm/min | 3740 |

| Cross slide rapid traverse speed | mm/min | 1870 |

| Metric thread grade/range | mm | 22/1-15 |

| Inch thread grade/range | T.P.I | 26/14-1 |

| Traverse of Cross slide | mm | 430 |

| Max.traverse of turret | mm | 250 |

| Tailstock quill travel | mm | 250 |

| Tailstock quill Dia/taper | | 100mm /Morse NO.6 |

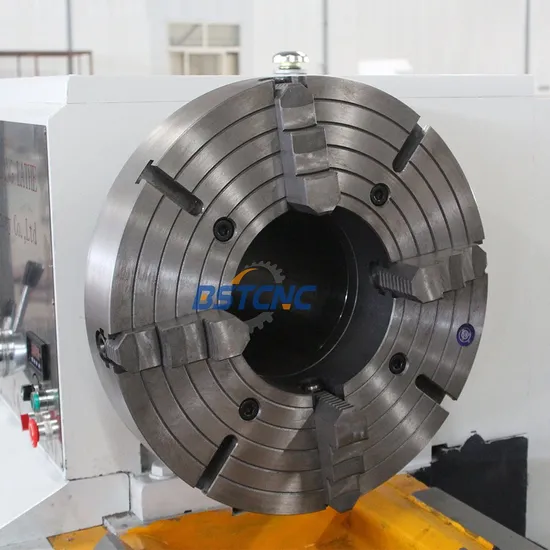

| Chuck | | φ630 3-jaw chuck

φ780 4-jaw chuck |

| Overall dimensions(L*W*H) | mm | 3850x1650x1600 |

| Machine weight | T | 6.5/7.2 |

Standard configuration: Optional configuration:

-With 4 jaws double manual chuck (630mm) -Steady rest ,follow rest , back steady rest;

-With 4 station manual tool post and manual tailstock -Digital readout ;

-With Whole casting bed -Processing length: 2000mm,3000mm,4000mm,5000mm;

-Voltage 380V/220V/415V ,3 Phase

Detailed Photos

Company Profile

Cooperation Customers

Packaging & Shipping

FAQ

>>

Tyre Wheel Valve MS525 AL Tubeless Bolt-in Replaces TR412 TR413 TR414 TR418

>>

hot sell colorful plasic spike studs glue on clothing bags garment accessories

>>

Kl300 Sereis Feed and Wood Pellet Making Machinery Wearing Parts

>>

China Top Quality Preform Injection Molding Machine Pet Bottle Preform Making Machine

>>

Hand Tools 2 Ton Scissor Jack for Truck Repair

>>

State Grid Power Cabinet Communication Server Monitoring Cabinet Power Cabinet Communication Cabinet Integrated Floor standing DC Cabinet

>>

Driven Head Living Tools CNC Lathe

>>

Stainless Steel Heating Mixing Cooling Tank for Food Industry

>>

Shearing Machine Molds, Upper and Lower Dies, Shearing Tools

>>

Perforated Casing Pipe

>>

Heavy Industry King of Cost Performance Hls60 Concrete Mixing Plant

>>

Liquid Oxygen/Argon/Nitrogen Cryogenic Dewar Cylinders

>>

electric gate worm, and worm gearbox for electric vehicles

>>

High Pressure 32MPa Milk Homogenizer for Sale

>>

High Efficiency Energy-Saving Hbe Liquid Ring Gas Vacuum Pump

>>

Linear Type Pet Can Blow Molding Machine

>>

4-inch manual Marshall Stability Test Machine

>>

Single Stage Cooling Condensate Removal Pump Suitable for High-Efficiency Gas Furnaces

>>

Aotai High Energy Saving Durable Two-Platen Injection Molding Machine

>>

Gear Reducer Lead Screw Small Driver Stepper Motor