|

US$6,000.00-18,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Process Combination Type

Compound Die

After-sales Service

Supported for Long Life

Pilot Moulding

We Provide

Prototype

Molding Samples Will Be Provided After Trial

Payment Term

30% in Advance, 60% Before Ship, 10% After Install

Transport Package

Wooden Box

Production Capacity

30 Sets/Month

Product Description

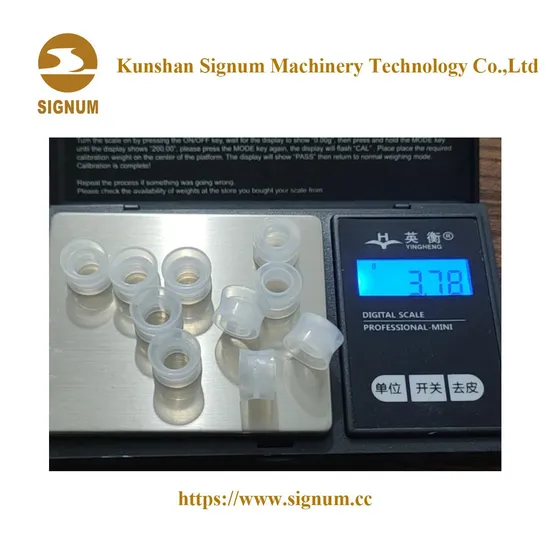

Detailed Photos

Product Description

Item Name

| Plastic Injection Lotion Pump Mist Sprayer Mould

|

mould material

| P20,H13,718,2738,NAK80,S136, 45#

|

mould base

| LKM,HASCO

|

Cavities

| As per customer's need

|

Runner

| cold or hot runner

|

Design software

| UG,PROE,CADetc.

|

Plastic material

| PP,PE,Nylon (PA66), ABS,PC PET

|

Delivery time

| 45 days

|

Packaging & Shipping

FAQ

FAQ About Plastic Mould:

Q1: What kind of molds do you make? A1: We mainly make plastic injection and progressive stamping molds. Q2: What types of files do you accept (drawings)? A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc. Q3: What kind of steel do you use for plastic mouldings? A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc. Q4: Can you provide the steel certificate and heat-treatment certificate? A4: Yes, We can provide steel certificate or hardness certificate to prove. Q5: Whtat is the lead time of plastic injection mold? A5: Around 30 days. Varying from 15 to 60 days. Q6: How do you deal with spare parts? A6: We prepare necessory spare parts with delivery of the molds for free. And will make as per customers' order. Q7: How do you pack the moulds? A7: We pack the plastic moulds with wooden box after auti-rust oil protection and shink film wrapping.

>>

Shenzhen Factory P8 Sports Clock Heart Rate Blood Pressure Monitor Square Smart Watch for Men Women

>>

Small business water bottle filling machine/produuuction line for cheap price

>>

Clay Brick Automatic Frame Stacking Machine for Tunnel Kiln Brick Making Machine in Brick Production Line

>>

Animal Waste Screw Press Sludge Dewatering Solid Liquid Separator

>>

New Style Barber Chair for Sale Hairdressing Chair for Salon

>>

Length 12mm Ar Glass Fiber Chopped Strand

>>

Accident-Reducing Galvanized Traffic Barriers for Road Safety Highway Guardrails OEM

>>

Solar Connectors PV Panel Cable Wire Crimper Crimping Tool Plier

>>

Custom Plastic Injection Molding for Automotive Spare Parts

>>

Brilliant Rainbow Silver Holographic Laser Unicorn Chrome Magnetic Nail Powder

>>

Hot Sale Table Stoves Gas Hob Tempered Glass Panel Gas Stove

>>

LED Video Wall Processor Novastar Vx400s-N All-in-One Controller

>>

Tractor Disc Plow for Plowing Made in China by Horsen Heavy Duty Farm Equipment Agri Disc Harrow

>>

High Automation and Enhanced Safety Strong Load-Bearing Capacity Labyrinth Seal Single Cylinder Cone Crusher for Construction

>>

What are the respective advantages and disadvantages of U-shaped spiral conveyor, tubular spiral conveyor and non-axis spiral conveyor

>>

17mm RF Coaxial SMA Female Connector, SMA-KWE PCB Welding Right Angle SMA Connector

>>

Hot selling membrane shell 4040 FRP reverse osmosis membrane shell

>>

Inspection Access Anti-corrosive Grey Weathertight Hatch Cover For Boat Yacht Marine

>>

F30 Carbon fiber Front grille Kidney Grille Dual Slat Grille For the BMW 3 Series F30 F35 2012-2019

>>

Secoisolariciresinol Diglucoside From Flaxseed Extract