|

US$68,600.00-305,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Automatic Grade

Automatic

Certification

CE, RoHS, ISO 9001, GS, CE, RoHS, ISO 9001

Process Usage

Metal-Cutting CNC Machine Tools

Numerical Control

CNC/Mnc

Processing Precision

0.04~0.05(mm)

Performance Classification

Economical CNC Machine Tools

Tool Changer

Side-Mounted Manipulator Type

Guideways

Taiwan Linear Guideways

Control System

Siemens GSK Knd Fanuc Mitsubishi

Machine Type

Gantry Machining Center

Processing

Metal Cutting CNC Milling Machine

Showroom Location

Canada, Turkey, UK, Us, Italy, Russia, Indian, SA

Voltage

380V50Hz and Customer Request

Key Selling Points

Multifunctional

Exported Country

Russia, Germany, American, UK, Indian

Transport Package

Moisture-Proof Inner Packaging,Wooden Case Outside

Specification

9000*4800*4000 mm

Production Capacity

200 Sets/Year

Product Description

1. Experience precision like never before with the China CNC Large Horizontal Machining Center GMC321 GF-2214. Designed for excellence, this state-of-the-art machine boasts unparalleled accuracy and reliability, ensuring your production processes are streamlined and efficient. This cutting-edge machining center is engineered to redefine precision, offering you the ultimate solution for high-performance metal cutting. With its advanced features and robust construction, the GMC321 GF-2214 promises to elevate your manufacturing capabilities to new heights, delivering consistent and superior results every time.

Product Description

1.1 DESCRIPTION The Professional Gantry Vertical CNC Double Column Metal-Cutting Machining Center, meticulously crafted by NANJING NEWSIV EQUIPMENT CO., LTD., exemplifies pinnacle engineering and state-of-the-art technology. This sophisticated machining center is designed to cater to demanding industrial applications, providing unparalleled precision, reliability, and efficiency. Its robust structure and advanced CNC capabilities ensure that every cut is executed with the utmost accuracy, making it an indispensable asset for high-performance metalworking operations. This state-of-the-art equipment has been engineered to meet the highest industry standards, offering versatile solutions for the most complex machining tasks. Ideal for large-scale production environments, it stands as a testament to superior craftsmanship and innovative engineering, ensuring consistent and exceptional results in every use.

FEATURE

1.2 FEATURE

Delivering exceptional performance, unwavering precision, and unmatched rigidity.

Crafted from premium-grade resin sand casting with a robust box-shaped design, this machine tool exemplifies durability and strength.

Undergoing meticulous aging treatment to eradicate internal stress, ensuring enduring stability.

The entire machine exhibits superior rigidity and strength, offering remarkable cutting resistance and exceptional precision.

Automatic Tool Change System

Experience the velocity and reliability of our arm-type tool change system, ensuring swift, smooth, and dependable tool exchanges.

Controlled by sophisticated PLC software, the tool change process is completed in approximately 8 seconds, significantly reducing non-cutting time.

Rotatable Control Box

The rotatable seat-type control panel and portable handwheel operation box provide unmatched convenience.

Operators can access it from any position, with the foot switch facilitating easy tool clamping and release on the spindle head.

Servo Motor

The servo motor drives the screw rod directly via coupling, minimizing vibration and enhancing precision across all three axes.

Equipped with a servo motor featuring a built-in absolute encoder for indirect displacement measurement, forming a semi-closed loop system to ensure precise positioning accuracy. The three-axis positioning is managed by the advanced numerical control system.

1.2 PARAMETERS

| Specification | | GF-2214/2514/3014/4014 | GF-2217/2717/3017/4217 | GF-2718/3218/4218 | GF-2722/3022/42222/5222/6222 | GF3025/4025/5025/6025 |

| X-axis travel | mm | 2200/2500/3000/4200 | 2200/2700/3000/4200 | 2700/3200/4200 | 2700/3000/4200/5200/6200 | 3200/4200/5200/6400 |

| Y-axis travel | mm | 1450 | 1700 | 2000 | 2400 | 2800 |

| Z-axis travel | mm | 850 | 850 | 1000 | 1000 | 1100 |

| Gantry width | mm | 1400 | 1700 | 1800 | 2200 | 2500 |

| X/Y/Z guide track | - | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track |

| Worktable size | mm | 2200/2500/3000/4000x1200 | 2200/2700/3000/4200X1500 | 2600/3000/4000X1800 | 2500/3000/4200/5000/6000X2000 | 3200/4200/5000/6200X2300 |

| Table form (,No.*screw hole) | mm | 7-22*150 | 7-22*220 | 9-22*180 | 9-22*203 | 9-22*226 |

| Spindle type | BT | BT50 | BT50 | BT50 | BT50 | BT50 |

| Spindle speed | rpm | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spindle dia | Ø | 190 | 190 | 190 | 190 | 190 |

| Spindle motor | kw | 15/18.5 | 15/18.5 | 15/18.5 | 22/26 | 22/26 |

| X/Y/Z quickly move speed | m/min | 15/15/12 | 15/15/12 | 15/15/12 | 12/12/12 | 12/12/12 |

| Max cutting feed speed | - | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Tool magazine capacity | pcs | 24 | 24 | 24 | 24 | 24 |

| Max tool weight | Kg | 18 | 18 | 18 | 18 | 18 |

| X/Y/Z axis position accuracy | mm | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 |

| X/Y/Z axis repeat position accuracy | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Max.loading of worktable | g | 4000/5000/6000/8000 | 5000/5000/6000/8000 | 6000/8000/10000 | 7000/9000/11000/13000/16000 | 8000/12000/16000/19000 |

Distance from the spindle front

end to worktable center | mm | 270-1120 | 165-1025 | 150-1150 | 150-1150 | 200-1300 |

| Machine size (L×W×H) | m | 6.4/7.4/8.4/10x4x3.7 | 6.6/7.6/8.6/10.6X4.5X3.5 | 7.5/8.5/10.5X4.7X3.8 | 7.5/8.5/10.5/12.5/14.5X5X3.8 | 8.5/10.5/12.5/14.5X5.7X4.5 |

| Machine weight | t | 16/19/22/25 | 18/21/24/27 | 23/26/31 | 24/27/30/35/40 | 32/37/42/47 |

| Specification | | GF3228/4228/5028/6228 | GF-3232/4232/5232/6232 | GF4037/5037/6037/8037 | GF4042/5042/6042/8042 |

| X-axis travel | mm | 3200/4200/5000/6200 | 3200/4200/5000/6000 | 4200/5200/6200/8200 | 4200/5200/6200/8200 |

| Y-axis travel | mm | 3200 | 3300 | 4000 | 4500 |

| Z-axis travel | mm | 1100 | 1250 | 1250 | 1250 |

| Gantry width | mm | 2800 | 3200 | 3700 | 4200 |

| X/Y/Z guide track | - | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track | XY:Linear guide track

Z:Slide guide track |

| Worktable size | mm | 3200/4200/5000/6200X2300 | 3200/4200/5000/6000X2700 | 4000/5000/6000/8000x3000 | 4000x5000x6000x8000x3000 |

| Table form (,No.*screw hole) | mm | 9-22*226 | 13-22*180 | 13-28*200 | 13-28*200 |

| Spindle type | BT | BT50 | BT50 | BT50 | BT50 |

| Spindle speed | rpm | 6000 | 6000 | 6000 | 6000 |

| Spindle dia | Ø | 190 | 190 | 200 | 200 |

| Spindle motor | kw | 22/26 | 22/26 | 22/26 | 22/26 |

| X/Y/Z quickly move speed | m/min | 12/12/12 | 12/12/12 | 15/15/12 | 12/12/12 |

| Max cutting feed speed | - | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Tool magazine capacity | pcs | 24 | 24 | 24 | 24 |

| Max tool weight | Kg | 18 | 18 | 18 | 18 |

| X/Y/Z axis position accuracy | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| X/Y/Z axis repeat position accuracy | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| Max.loading of worktable | g | 9000/12000/15000/18000 | 16000/20000/23000/26000 | 16000/20000/26000/30000 | 16000/20000/26000/30000 |

Distance from the spindle front

end to worktable center | mm | 200-1300 | 175-1425 | 250-1500 | 250-1500 |

| Machine size (L×W×H) | m | 8/10/12/14X6X4.8 | 9/11/13/15X6.5X4.8 | 11/13/15/19X7X5 | 11/13/15/19X7.5X5.2 |

| Machine weight | t | 35/40/45/50 | 40/45/50/60 | 50/57/65/80 | 55/63/73/93 |

1.4 STANDARD ACCESSORIES

| 1 | 24 tool magazines | 6 | Tri-color warning light | 11 | Spindle cooling | 16 | Portable chip blowing air gun |

| 2 | Workpiece Cooling System | 7 | Machine cleaning water gun | 12 | Fully enclosed protective cover | 17 | Large flow chip flushing device |

| 3 | Automatic lubrication system | 8 | Spindle output water | 13 | Foundation screws and pads | 18 | Spindle nose labyrinth dust blower |

| 4 | Spindle air curtain dustproof system | 9 | Electric cabinet heat exchanger | 14 | Tools and Toolboxes | 19 | Chip trolley |

| 5 | LED working light | 10 | Network transmission and CF card function | 15 | Double screw conveyor& chain chip conveyor | 20 | Transformer |

2. SERVICE

2.1TRAINING AND INSTALLATION

2.2AFTER SALES

1. From the BL date, the manufacturer provides a comprehensive one-year 'three guarantees' service for the product (user-induced damage will incur additional costs).

2.

In the event of a machine tool malfunction, the manufacturer will accurately diagnose the issue and provide immediate assistance upon receiving user feedback. If the cause is indeterminate,a response will be provided within 24 hours.

2.3 Package

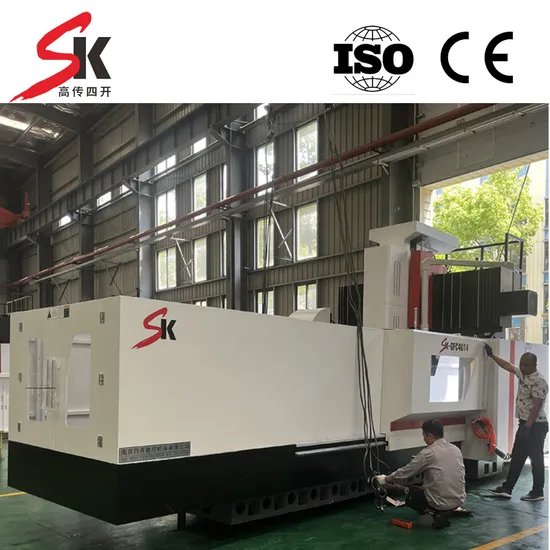

FACTORY WORKSHOP

3.Discover the Advanced Capabilities of our FACTORY WORKSHOP, where state-of-the-art technology meets unparalleled craftsmanship. Experience precision engineering and cutting-edge innovation as we bring your visions to life with our exceptional expertise and dedication.

Company Profile

4. Company Strength

4.1 General Situation

Founded in 1993, Anhui Gaochuan Sikai CNC Equipment Manufacturing Co., Ltd. (formerly Nanjing Sikai), now known as NanJing Newsiv Equipment Co., Ltd., made a strategic move to Ma'anshan, Anhui in 2021. This transition marked a significant evolution in our journey, aligning us with new opportunities and growth.

As a high-tech enterprise, we excel in the design and manufacturing of CNC machine tools. Our core products are endowed with completely independent intellectual property rights, and many of our series have proudly earned the prestigious Jiangsu Province High-tech Product Certificates. This recognition underscores our innovative capabilities and commitment to excellence.

Acknowledged as a high-tech enterprise, we joined forces with China Transmission Group in 2010. With the group's robust support, we consistently pursue excellence and self-improvement. We collaborate with renowned international and Taiwanese machine tool companies to achieve superior quality and performance, aiming to compete at the highest global standards. Our partnerships enable us to bring cutting-edge technology and unmatched precision to our products.

4.2 Participation in Exhibitions

Certifications

4.3 Certifications: Our unwavering dedication to excellence is affirmed by an array of prestigious certifications. These accolades guarantee that our Vertical CNC Milling Double Column Heavy Duty Metal Cutting Machining Center adheres to the most rigorous standards of quality and safety.

4.4 FAQ: Explore our detailed FAQ section, where we provide thorough answers to all your pressing inquiries regarding our advanced machining center. From comprehensive technical specifications to operational guidance, we ensure you have the complete information to make a well-informed decision.

5. Other Products: Delve into our vast selection of pioneering equipment beyond the Vertical CNC Milling Double Column Heavy Duty Metal Cutting Machining Center. Uncover cutting-edge solutions meticulously crafted to fulfill diverse industrial requirements with unparalleled precision and performance.

>>

Hot Sale Wholesale Kids Sports Golf Set Toys

>>

High Gain Dual Handheld 8 Port Directional Panel Antenna Customized Frequency

>>

candy jelly bag mylar small sugar paper sachet bags

>>

Diameter 2.5m of Pneumatic Rubber Fender

>>

Agricultural Li-ion Cell 12V Electric Backpack Battery Sprayer (XF-20M28) 20L 5gal

>>

Full Servo Women Sanitary Napkin Production Line Underpad Manufacturing Machine

>>

CAS No. 3441-14-3 Direct Red 23 Direct Scarlet 4BS Dye

>>

OEM tri Wheel Sugarcane Grab Loader Small Sugarcane Loader for large Power Reserves

>>

car body puller FAST-D3

>>

Factory Price Wholesale Silicone Stress Relief Pop Water Balls for Kids

>>

CATV CCTV Cable Manufacturer 50ohm Coaxial Cable RG8 RG8U

>>

Adjustable Lower Die and Manual Adjustment of The Bending Angle

>>

Android POS Oneline Offline Thermal Printer

>>

Custom Printing Cotton Baby Pajama Set Winter Cartoon Children′s Pajamas Girls′ Sleepwear

>>

China Supplier Customized Logo Printed Handmade Wireless Earphone Electronic Earbuds Paper Packaging Boxes With Lid Handle

>>

Livestock Massage Brush Cow Brush Roller for Enhanced Horse Grooming and Care

>>

4G SD Card Mdvr GPS Tracking School Bus Truck Support 256GB SD Card 1080P DVR Camera System 4CH Car Black Box

>>

Terrazzo Ground Floor Polishing & Grinding Machine

>>

Hote Sale Note30+ 6.3inches 1+8GB AC70 Black Purple and Gold Mobile Phone

>>

Disposable PP+PE Surgical Level 2 Protective Apparel Light Weight Isolation Gown