|

US$15,000.00-80,000.00

|

1 Piece

(MOQ)

|

Basic Info.

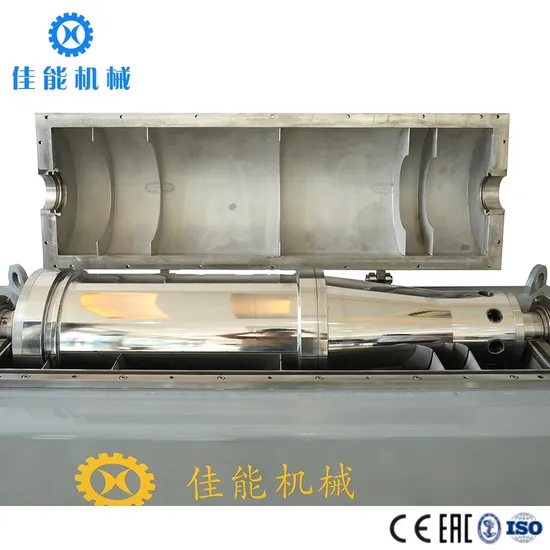

Separation Mode

Sedimentation Type

Operating Type

Continuous Type

Centrifuge Type

Horizontal Spiral Centrifuge

Material

SS304 or SS316 L or Ti

Application

Solid Liquid Separation

Separation

3 Phase Separation

Discharge Type

Self-Cleaning

Separation Method

Sedimentation Type

Electronic Component

ABB or Siemens

Transport Package

Wood Case

Production Capacity

500/Year

Packaging & Delivery

Package Size

600.00cm * 150.00cm * 180.00cm

Package Gross Weight

9500.000kg

Product Description

Company Profile Jiangsu Jianeng Machinery Manufacturing Co., Ltd. stands proud as a prestigious high-tech manufacturing enterprise under the complete ownership of Nanjing Jianeng Machinery Manufacturing Co., LTD. Since our founding moment in 2001, we have distinguished ourselves in the realms of research, design, manufacturing, and service. Originally nestled in the Nanjing Yuhuatai District, our avant-garde new facility now graces Jinyuan Road No. 7 within the Xuyi Economic Development Zone in Huaian City, Jiangsu. This vast and impressive establishment envelops 58,700 square meters, featuring a 38,600-square-meter workshop, a sophisticated 4,000-square-meter office building, and a 2,100-square-meter science and technology hub. Committed to crafting China's preeminent disc and decanter centrifuges, we boast a formidable annual production capacity of 2,000 sets.

Main technical parameters ofdecantercentrifuge |

Model |

LW250

Series |

LW350

Series |

LW450

Series |

LW530

Series |

LW580

Series |

LW650

Series |

U. mm

Drumdiameter |

250 |

350 |

450 |

530 |

580 |

650 |

m³/h

Water lux |

3 |

10 |

20 |

30 |

40 |

50 |

U. w

Main motor power+

Auxiliary motor power |

15+4 |

22+7.5 |

30+11 |

45+15 |

55+15 |

75+22 |

U. kg

Weight |

1100 |

2300 |

4500 |

5500 |

6500 |

9500 |

U. m

Overall dimension |

2.7X0.7X0.85 |

3.54x0.92x1.05 |

4.35x1.12x1.35 |

4.6x1.25x1.52 |

5.12x1.3x1.48 |

5.58x1.35x1.65 |

Procedure Control At Jiangsu Jianeng Machinery, we take immense pride in our cutting-edge quality inspection and test center. Equipped with a suite of advanced instruments such as chemical analyzers, product test benches, high-precision dynamic balances, coordinate measurement machines, Vickers hardness testers, imagers, flaw detectors, profilers, and coding machines, we ensure unmatched product excellence and precision. Our rigorous and thorough testing procedures, complemented by sophisticated equipment, assure extraordinary product quality and unparalleled reliability throughout every manufacturing stage. Product Equipment Jiangsu Jianeng Machinery is equipped with an extensive suite of advanced production capabilities, including machining, surface treatment, cold welding, testing, test stands, installation, and commissioning. Within our state-of-the-art facility resides an arsenal of over 300 cutting-edge equipment pieces, such as CNC boring and milling centers, CNC turning centers, gantry machining centers, advanced testing tools, parts painting production lines, shot peening production lines, welding equipment, surface treatment machines, and high-precision dynamic balancing equipment. This comprehensive array of machinery empowers us to maintain full process independence and deliver unparalleled product excellence. With top-tier processing and testing equipment, a cadre of highly skilled technical personnel, scientific manufacturing techniques, and strict adherence to national military standards and quality management systems, we uphold our core tenets of 'management, quality, and efficiency' in every facet of our business operations. One-stop Services We provide an all-encompassing suite of one-stop services, encompassing ample spare parts supply, expert commissioning, repairs, maintenance, and professional technical consultations, all designed to support and enhance the experience of our valued customers. Sufficient Spare Parts and Standby Machines Our robust independent production capabilities, spanning the entire process, empower us to consistently deliver superior products that meet and often exceed industry standards.

>>

New Manually One Plastic Contact Lens Cleaner Washer Cleaning Lenses Case Tool

>>

High quality European standard sprocket

>>

Ship Launching Marine Inflatable Rubber Roller Airbag

>>

High Frequency ERW Round Square Pipe Making Machine for High-Quality Ms Gi Iron CS Steel Tube Mill Roller Manufacturing

>>

Supply Large Quantities of Ruiyi Brush Wire, Wear-Resistant Professional Car Wash,

>>

QLM-508YC BMT 55 turret high durability CNC machine slant for turning milling and drilling

>>

Performance Racing Car Universal Engine Lift Plate for Chevy Performance Parts

>>

Hollow Block/Curbstone/ Paver Mould for Block Making Machine

>>

High-Elastic Shoulder Straps Expose The Back V Peach Hip Belt Chest Pad Tight-Fitting Slimming Yoga Jumpsuit, Quick-Drying Sports Yoga Fitness Cycling One-Piece

>>

Manufacturer Supplier Car Accessories Tracker car Reinforcement under the front bumper skin For Chevrolet 26227713

>>

Motorized Flow Table for Cement Mortar

>>

Three Roller Chicken Farms Pellet Crumble Feed Machinery

>>

Front and Rear Sway Bar Link for 118i 120i 125i F52 2016-2019 Suspension Parts Kit Auto Parts

>>

Vacuum Insulated Glass Low-E Tempered VIG Glass

>>

Customized Euro Shopping Plastic Trolley Coin Keychain

>>

CAT 6M9149 6M-9149 Caterpillar/Mitsubishi POINT HEAD BOLT 12 for MARINE ENGINE 3304 3304B

>>

Six Cavity Pet Stretch Plastic Fully Automatic Blowing Machine Blow Moulding Machine

>>

Chl Auto Engine Chassis Parts Sunroof Accessories Diagram

>>

TK1027-19 Timing Chain Kit VVT Pulley FOR SMART M160 Crossblade Roadster Fortwo Cabrio City-Coupe

>>

Dish Drainer Racks Kitchenware Storage Drain Dish Rack Stainless Steel Kitchen Plate Drying Rack