US$1.50

1-1,000 Kilogram/Kilograms

US$1.45

1,001-3,000 Kilogram/Kilograms

US$1.30

3,001+ Kilogram/Kilograms

Basic Info.

Model NO.

DY275- PAN Fiber 6MM

Feature

Anti-Cracking Agent

Fiber Type

Monofilament in Bundles

Function

Concrete Reinforcement, Improve Stability

Structure

Miscellaneous Chain Synthetic

Product Name

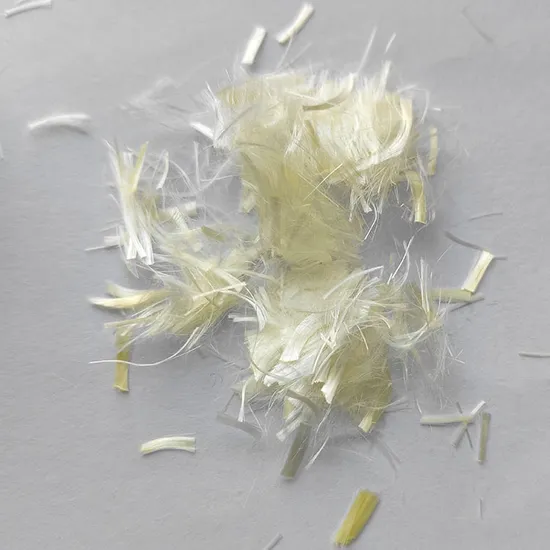

Monofilament Synthetic Pan Polyacrylonitrile Fiber

Equivalent Diameter

15+/- 2 Um

Acid & Alkali Resistance

Ultimate Tensile Strength Retention ≥95%

Density

1.18 to 1.2 g/cm3

Elastic Modulus

>6000 MPa

Heat Resistance

No Melting at 200 Celsius

Payment Term

30% T/T Prepaid, 70% Against Copy of B/L

After-Sales Service

Suggestions on Mix Design, Dispersing Solution

Crack Elongation

12% to 35%

Production Time

15-20 Days

Transport Package

1 Kg Per Small Bag, 20kg Per Big Bag

Specification

6, 10, 12, 15 MM

Production Capacity

10000 Tons/Year

Packaging & Delivery

Package Size

41.00cm * 40.00cm * 25.00cm

Package Gross Weight

21.150kg

Product Description

Product Description Besides the general advantages of chemical fiber, different types of synthetic fibers have unique properties such as high strength, light weight, easy to wash and fast drying, not mildew and moth.

The polyacrylonitrile fiber is a new type of concrete special fiber that our company has introduced the advanced technology of the United States. The engineering community has a reputation for the 3rd generation of concrete fiber. The fiber is to adopt a cold area special plants as raw materials, through special chemical and physical process refined but become, have natural affinity and high strength model, which can effectively improve the mechanical properties of concrete, freezing-thawing resisting sexual and permeability resistance.

Main Performance:

1. Natural division of plant cells,natural hydrophilic;

2. Excellent grip of concrete;

3. Large fiber ratio surface area;

4. High toughness/High strength;

5. Convenient construction;

6. Strong acid and alkaline resistance;(strong retention rate not less than 95%);

7. Harmless to human body and environment.

Estimating Data:

The dosage rate is dependent on the application. The general dosage range is 1kg/m3.

Main Applications:

1. Water conservancy projects, dams, aqueducts, aqueducts and water supplies;

2. High-speed railway, Bridge, Tunnel, and no track;

3. Industrial and Civil Buildings, Underground Structural Works, etc.;

4. Marine engineering, cross-sea bridge, port wharf and so on.

Packing:

1 Kg Per small bag, 20kg per big bag, or packed as request. Product Parameters Technical Parameters:

| Equivalent Diameter | 15+/- 2 Um |

| Fiber Length | 6,10,12,15 MM |

| Melting Point | 200 Celsius |

| Density | 1.18 to 1.2 g/cm3 |

| Acid & Alkali Resistance | Ultimate tensile strength retention ≥95% |

| Crack Elongation | 12% to 35% |

| Elastic Modulus | >6000 Mpa |

| Tensile Strength | 500 Mpa |

Detailed Photos

Company Profile Ganzhou Daye Metallic Fibres Co., Ltd. specializes in manufacturing various specifications of concrete fiber, concrete mixer, steel fiber dispenser, steel fiber making machine, UHPC dry-mix and precast products, including RPC sidewalk, Cable Cover, Cable Groove, Guardrail, Bridge Shutters, Slope Protection Bricks, Sound Barriers, Metro Evacuation Platform and so on. We have very strong technical support, advanced product line and precise instrument, annual output steel fiber is over 15,000MT, ultra-high performance concrete dry-mix 20,000MT.

Our company has passed the IS09001 certification and CE certification. We passed strict testing supervised by National metallic quality supervising and testing center, all the technical indicators can reach the industry requirements which required by YB/TlSl-1999, Technical specification for fiber reinforced concrete structures (CECS38:2004) ASTM-A820 standard.

Our steel fiber has been widely used in many important projects such as Dam, Power Plant, Express way, Bridge, Tunneling, Taxiway, Railway Sleeper, Basement and Anti-aircraft project, etc. It is well sold all over the world, and enjoys very good reputation among our customers.

FAQ Q: Are you factory?

A: Yes, exactly. We are specializing in building items and related machines since 2002. We are located in Ganzhou City and have 20000 M2 production base. All stuff of Daye company are always glad ready to service you! Daye Fiber manufactures steel fibers that plays a strengthening role in concrete. Steel fibers are widely used in important engineering components. Our fibre can greatly increase the tensile and flexural strength of UHPC. These fibers comply with the standard of ASTM A820. Since we are a factory, we can produce all kinds of steel fiber. Our production rate is 10 tons per day. We have attained ISO and CE certificates. More information, please visit our website https://gzdymf.en.made-in-china.com

Q: Is trial order acceptable?

A: Yes, a trial order with lower MOQ is always accepted for quality and market evaluation.

Q: When can I receive my products?

A: Sample order: 1 - 3 days; Mass production: 15-20 workdays .

Shipping: 1) 7-9 workdays by Express.

2) 9-11 workdays by Air.

3) 20-25 workdays by Sea.

Q: What kinds of fibers can you supply?

A: We manufacture fibers according customer requirement. Steel fiber types includes,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Q: What are applications of Daye steel fiber?

A: a) Tunnel pre-treatment(primary support)

b) Tunnel forming(permanent lining)

c) Slope stabilization

d) Ditch excavation support

e) Industrial floor

f) Precast concrete element

g) Concrete restoration

h) High performance concrete

Q: What are technical advantages of Daye steel fiber?

A: a) Improve mechanical performance of concrete

b) Provide uniform distribution throughout concrete with excellent mixing

c) No balling or caking by adopt correct mixing method

Q: What are economic benefits of DAYE steel fiber?

A: a) Replace of rebar mesh

b) Reduce concrete volume

c) Save construction time and cost

d) Reduce excavation volume

e) Available for jointless floor.

>>

Outdoor Camouflage Sport Knee Elbow Protective Pads Hunting Hot

>>

Mini manual wheat and rice combine harvester

>>

China Manufacture Cattle Feed Production Line

>>

Royal Blue Custom Puff Printing Summer T-shirt For Men and Kids

>>

Low Power Deep Engraving Industrial Round Corner Cabinet Laser Marking Machine

>>

Small Electric Three-Wheeled Rear Loader Garbage Truck Manual Transmission Baterry Tricycle Vehicles New Used Export

>>

Paragliding Fabric PU Coated 100% Nylon Taffeta Ripstop Waterproof Fabric

>>

ALL CAR BODY KITS Exterior Parts GAPV Brand For Toyota For Lexus For Nissan For Mitsubishi For Honda For Mazda For Hyundai

>>

Dual Protocols M.2 NVME(PCIe & SATA) SSD Storage Adapter PCIe Card

>>

Lihua High-Quality Aluminum Shell Hoist with CE Tested

>>

Reliable Dongfeng 58000L Compression Truck for Urban Garbage Disposal

>>

2022 New High Performance Mini Excavator 1.8 Ton Mini Excavator with 0.06cbm Bucket for Sale

>>

No-Needle Mesotherapy Device

>>

Custom Logo Outdoor Sports Men Sun Glasses UV400 Protection Cycling Photochromic Sunglasses

>>

Factory hot on sale Anisun V3K5 wheel alignment machine price

>>

Competitive Price Conveyor Belt Uncured Cover Rubber for Belt Hot Splices

>>

Round Bevelled Polish Frameless Wall Mirror with Hooks for Bathroom

>>

High Speed Vertical Double PE, Single PE, Laminated Paper Cup Forming Making Machine

>>

Czz Power Window Regulator Lifter W/O Motor for Buick Excelle, Daewoo Lacetti 04-03, Chevorlet Lacetti 08-04, Chevrolet Optra 04-07, 96548080 FL

>>

Custom Made Coated Sand Shell Mold Casting Cast Iron Mud Pump Impeller