Basic Info.

Raw Material

Coconut Shell

Final Product

Coconut Shell Charcoal

Final Product Usage

Make Charcoal Briquettes

Carbonization Time

8-30hour

Instalation

Engineer Guide

Product Description

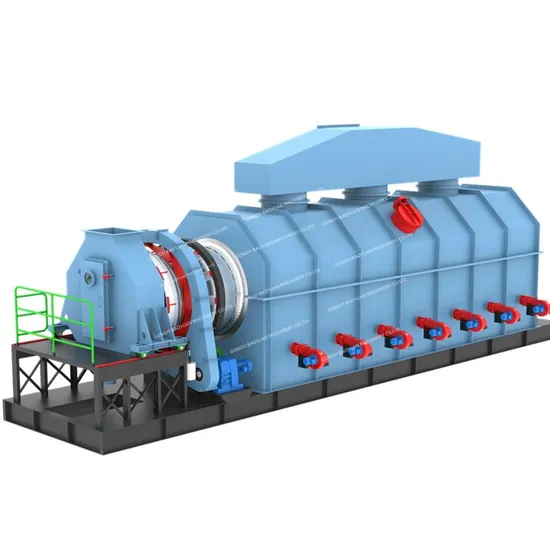

Continuous carbonization furnace is a carbonization equipment used for continuous feeding and production, primarily utilized to convert organic materials such as wood, wood waste, or plant residues into high-quality solid charcoal. It is a crucial tool for carbonization, enabling the transformation of volatile components in organic materials through the process of pyrolysis and carbonization at high temperatures, resulting in the formation of carbonized substances and the production of solid charcoal products. Compared to traditional intermittent carbonization furnaces, continuous carbonization furnaces boast several advantages, with the most notable being the ability to conduct the carbonization process continuously, thereby enhancing production efficiency and output. The working principle involves providing a high-temperature environment within consecutively arranged furnace chambers, where the raw materials are continuously fed into the chambers through a conveyor system, while the carbonized products are continuously discharged from the chambers. This continuous feeding and production approach streamline the manufacturing process, reducing downtime.

Continuous carbonization furnaces have also garnered significant attention due to their environmental-friendly emission reduction and energy-efficient characteristics. Typically designed in a closed manner, they effectively prevent harmful gas leakage and are equipped with emission gas treatment systems, effectively reducing the release of harmful gases such as carbon dioxide and nitrogen oxides, complying with environmental protection requirements. Furthermore, these furnaces incorporate internal heat exchange and heat recovery systems to fully utilize generated waste heat, lowering energy consumption and optimizing energy utilization.

In summary, the continuous carbonization furnace is a highly efficient and eco-friendly device that enables continuous carbonization, transforming organic materials into top-quality solid charcoal. Its continuous production approach, emission reduction capabilities, and energy efficiency make it a significant technology in the field of carbonization.

Product Application

Raw materials seeds;

shells and pits of tree-fruits;

wood chips;

bamboo;

shrubby and other plant materials, the fraction of which is from 5 to 30 mm with a moisture content of not more than 15%.

Coconut shell

| Walnut shell

| Hazelnut shell

| Wood chips

| Bamboo

|

Coconut shell charcoal

| Shell charcoal

walnut

| Hazelnut shell charcoal

| Wood chips charcoal

| Bamboo charcoal

|

Palm kernel shell

| Pits of olives

| Pits of date

| Peach Shell

| Hawthorn Seed

|

Palm kernel charcoal

| Pits of olives charcoal

| Pits of date charcoal

| Peach Shell charcoal

| Hawthorn Seed charcoal

|

Received products Raw materials for obtaining activated carbon Raw Material for BBQ Charcoal Briquette and Industry Raw materials for the production of coal briquettes for hookahs (hookah, hookah coal) BIO-Char, as a fertilizer or hydroponic growth intended for the agricultural industry, is made from plant raw materials and does not contain harmful substances.

Technical parameters:

Model

| XY-800

| XY-1000

| XY-1200

| XY-1500

| XY-1800

| XY-2000

|

Cylinder

| Single Cylinder

| Single Cylinder

| Double Cylinder

| Double Cylinder

| Double Cylinder

| Double Cylinder

|

Cylinder diameter

| 800mm

| 1000mm

| 1200/700mm

| 1500/900mm

| 1800/1200mm

| 2000/1500

|

Capacity

| 200-300kg/h

| 300-400kg/h

| 450-600kg/h

| 600-800kg/h

| 800-1000kg/h

| 1000-1200kg/h

|

carbonization temperature

| 500-800ºC

|

carbonation reaction time

| 20-60min

|

Input size

| ≤20mm

|

Power

| 1.5kw

| 3kw

| 4kw

| 5.5kw

| 11kw

| 15kw

|

Working mode

| continuous

|

Company Profile

Baoyuan Machinery is a comprehensive enterprise that comprises R& D, test, manufacture, sales and service functions. We have succeeded in researching and supplying solutions with the following equipment: Drying equipment, activated carbon production equipment, building materials equipment, beneficiation equipment, crushing equipment and other products.

With our leading-edge technologies, advanced processing equipment and our corporate spirit of "innovation, pragmatism, unity, hard work and dedication", our company has the strength to meet the challenges from all aspects. We have the confidence to build "Baoyuan" into a world-renowned brand, provide quality services for the dryer and building processing industry, and achieve a win-win situation between the company and customers.

>>

China Manufacturer Supply Intellgent Horizontal Inducion Quenching / Hardening Gear Machine Tool for Various Gears

>>

Sinotruck HOWO Tx New Condition 8X4 Mixer Truck for Construction Work Self Loading Concrete Mixer Truck HOWO Used 377HP Mixer Truck

>>

stainless steel bamboo fence

>>

Self-Loading Concrete Mixer Truck Engine Customizable 2.6m3 (2.6-4.5m3)

>>

Double/Two Shaft Shredder for Recycling Metal Scraps/Used Tires/Soild Waste/Plastic/Wood

>>

Professional Edge Banding Machine for Efficient Woodworking Projects

>>

TM-8812 Ultrasonic Metal Thickness Gauge Portable Digital Metal Ultrasonic Thickness Gauge

>>

Bridge Expansion Joint, Modular Expansion Joint

>>

UICE high quality waterproof paddle bag kayak inflatable paddle board sup paddle shoulder bag handbag holder

>>

SHENGKE Luxury Woman Watch Special Dial Decorate With Diamond Milanese Stainless Steel Mesh Band Quartz Movement K0093L

>>

Construction Equipment Mini 4X4 Wheel Loader7500kg Articulated Backhoe Loader Diesel Wheel Backhoe Excavator Loader

>>

Sell Well Fashion Natural Rutilated Rabbit Hair Quartz Diameter 0.41-0.51 Inch Gemstone Crystal Bracelet

>>

Dental Chair

>>

Composite ceramic wear-resistant tube

>>

Brand New Rugby Short Made To Order From China Supplier

>>

Stainless steel special-shaped ditch cover plate, sump cover plate, galvanized welding ditch cover plate, firm and durable, high bearing

>>

Jwell&Bekwell 20L HDPE Plastic Jerry Can Tank Container Barrel Extrusion Blowing Blow Molding Making Machine

>>

64oz Stainless Steel Double Wall Insulated bottle Tumbler with Chug Cap

>>

Protective Workwear with Knit Cuff Latex-Free Coveralls SMS Disposable Isolation Surgical Gown

>>

800*600*750 Yellow Beech Flip Computer Room Multimedia Classroom Training Desks Conference Table