|

US$52,640.00

|

1 Piece

(MOQ)

|

Basic Info.

Processing Precision

0.01

Performance Classification

Mid-Range CNC Machine Tools

CNC Operating System

Siemens/Fanuc/Knd

Working Table Size

1400*1400mm

Left and Right Stroke (X)

1500mm

Back and Forth Stroke (Y)

1200mm

up and Down Stroke (Z)

1200mm

Distance From Spindle End to Worktable S

170-1200mm

X/Y/Z Rapid Traverse Speed

10/10/10 M/Min

Spindle Speed (Rpm)

8000-10000rpm

Machine Tool Positioning Accuracy (GB /

0.01

Repeated Positioning Accuracy of Machine

0.01

Power Supply Requirements

380V

Dimensions

3000*3500*2500mm

Transport Package

Customized

Product Description

Product Description

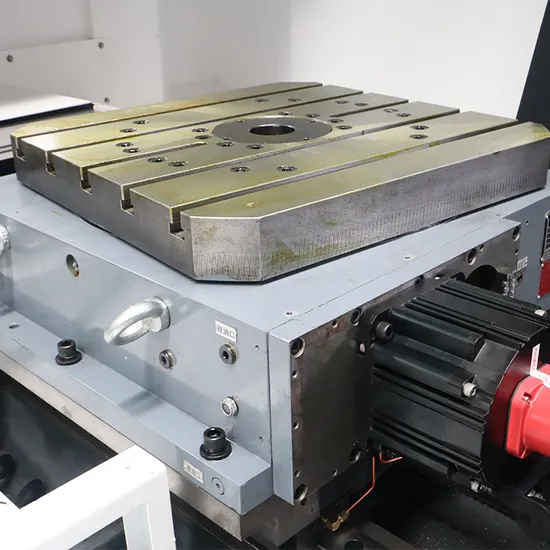

Main Structure

The horizontal machining center has high precision,high rigidity,integral column,double-wall structure,suitable for rough and fine machining, the bed adopts two linear guide rail and one hardened rail, heavy-duty roller line rail,super-sized,T-shaped moving column structure, to ensure the mechanical performance ,high rigidity and overall precision.The overall use of screw rods and line rails with larger specifications than those of the same industry can achieve large load, heavy cutting.and high rigidity.

Spindle

Fully enclosed hanging box type copper-containing casting structure,with imported tape and oversized clamp rails to ensure heavy-duty shock resistance; Japanese-made and Taiwan-made chrome-molybdenum alloy steel gears, precision grinding, ensuring high-speed and high-temperature durability.

Column

Closed "back double-layer casting structure,high-quality Mehana standard cast iron, two electric furnace aging and two vibration aging, to ensure long-term deformation without deformation.large size (140x70mm) support hard track (HRC55),Taiwan's equipment is super-fine grinding and fine shovel to ensure that the life of the purlins is extended by 50%.

Base

Super-sized double-layer box-type base, fine shoveling of each joint, multi-point hard contact to ensure the stability and durability of the whole machine. The use of larger-sized screws and line rails than the peers ensures high mechanical rigidity and machine precision.Integrated built-in structure of oil-water separation and chip removal ensures that the whole machine is environmentally friendly and economical.

Product Parameters

| Item | Main Parameter |

| CNC controller | | FAUNC-OI-MF |

| Worktable size | mm | 1400*1400 |

| Left and right stroke (X) | mm | 1500 |

| Up and down stroke(Y) | mm | 1200 |

| Front and back(Z) | mm | 1200 |

| Distance between spindle center and column guide rail | mm | 220 |

| Distance from spindle end face to working surface | mm | 170-1200 |

| work table T-slot (number/size/spacing) | mm | 10-20*100 |

| Taper hole of spindle (model/sleeve diameter) | mm | BT50/Φ190 |

| Use the stud model | | P50T-1 |

| Spindle speeds(rpm) | rpm | 8000 |

| X-axis ball screw specifications | mm | 63*20 |

| Y-axis ball screw specifications | mm | 63*12 |

| Z-axis ball screw specifications | mm | 80*10 |

| Position Accuracy GB/T 20957.4-2007standard) | mm | 0.01 |

| repeated positioning accuracy (GB/T 20957.4-2007standard) | mm | 0.01 |

| X/Y/Z axis shifts rapidly | m/min | 10/12/10 |

| Maximum cutting feed rate | m/min | 7 |

| Spindle drive mode | | Synchronous toothed belt drive |

| X/Y/Z Axis transmission mode and transmission ratio of shaft servo motor | | X-axis reducer direct coupling 2:1;Y and Z axis belt drive Y axis 2:1,The Z axis 2:1 |

| X,Y and Z axis guide rail specifications | | X, Z axis two 55 specifications heavy-duty roller linear rails,Two hard rails on the Y axis |

| Spindle power | KW | 22 |

| Servo motor parameters are recommended(X/NM,Y/NM,Z/NM) | N•M | 60/30/40 |

| Air source flow | | >0.5 |

| Power supply requirements | | 380V |

| Bed cushion height | mm | 30 |

| Work table loading | T | 6 |

| Overall dimensions | mm | 3000X3500X2500 |

| Light machine net weight | kg | 25t |

Company Profile

1.professional r&d team with 20 years of experience provide the over all solution for machine and processing.

2.Exporting to more than 50 countries worldwide

3.We own ISO certificate and SGS certification to prove our quality.

Henan Front Intelligent Equipment Co., LTD .

Henan FRT Group (Henan Front Intelligent Equipment Co.,Ltd.),its subsidiaries Luoyang Yujie Industry and Trade Co.,Ltd.,and Luoyang E-find Precision Bearing Manufacturing Co.,Ltd.,benefit from Luoyang's heavy-duty manufacturing advantages.Henan FRT Group has eighteen years experience of exploration and active innovation,has developed into a leading science and technology enterprise integrating scientific research and development, production and manufacturing, sales, technical services, and import and export trade.

FRT Group has been in the machinery industry for eighteen years and is committed to the three major fields of mechanical equipment, mechanical parts and precision bearings. The group has a group of experienced mechanical design teams, production and processing teams, assembly teams, and sales teams, and has excellent production equipments and processing technology, excellent testing instruments, complete product quality assurance system and after-sales service, consistently put product quality and users value first, adhere to integrity and long-termism, the group's core values allow customers achieving success is rooted in the hearts of company personnel.

Our Customers

FAQ

Q:What is your minimum order quantity and warranty?

A:MOQ is one set, and warranty is one year.

Q:How can I choose the most suitable machines ?

A:Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

Q:What is the payment Terms ?

A:T/T ,50% initial payment when order ,50% balance payment before shipment ; Irrevocable LC at sight .

4.Can your company send the technical personnel to our company and direct our workers for free?

A:When the machine arrive the buyer's installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD200.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

>>

Multifunctional wheat/corn/soybean/Roo/Millet thresher and sheller machine

>>

High Speed Woodworking PVC Sealing Edge Bander Machine

>>

Custom Logo Embossed Whiskey Glass Set Personalized Engraved Color Bamboo Wooden Hip Flask

>>

High Quality Cookware External/Internal Grinding Machine

>>

Children Car Baby Swing Car Ks-34

>>

Mixer Smoothie Professional Electric Power Blender Table Heavy Duty Commercial Blender

>>

2 Cavities Automatic Pet Plastic Bottle Making Blowing Machine

>>

Universal RAM Knee-type DRO Milling Machine X6436

>>

Small Hand-Held Cloth Cutting Machine Electric Circular Knife Electric Scissors Front Sewing Equipment

>>

high quality upgrade to HID Xenon headlamp headlight for BMW 1 series F20 halogen head lamp head light 2012-2014

>>

Factory Price Hualong 2025 Block Cutting Stone Processing Machinery CNC Bridge Saw Machine Hlsq-350

>>

Slide Door Switch

>>

Stainless Steel Aluminum Copper Brass Lathe Milling Turning Spare Machining Cutting Anodizing Machine Gear Auto Parts for Special Medical Equipment

>>

Full Automatic Tissue Making Production Line Band Saw Cutting Machine for Toilet Paper Machine

>>

Modern Curved Velvet Sofa Plush Comfort for Contemporary Living Spaces

>>

types of non-woven fabrics 100% viscose spunlace non woven fabric price for wet wipes

>>

Automatic High-Efficiency Servo Small Pot Paper Rewinding and Cutting Machine

>>

Chicken Cages Layer Poultry Farming Chicken Cage for Sale

>>

Heavy Plate Industrial Grade Aluminum Copper Alloy Plate High Precision Metal Sheet Hydraulic Leveling Straightening Machine

>>

Horizontal Paprika Particle Processing Double Shafts Paddle Mixer