|

US$30,000.00-50,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Advantage

Easy to Maintenance

Transport Package

Wooden Case

Product Description

The following information is for reference only Installation and wiring Forklifts can be used to lift the chassis for loading and unloading, or lifting tools such as cloth bags can be used

for lifting. Fix the equipment with expansion screws.

The wiring adopts a 2.5 square copper core cable and three-phase five wire wiring. The fluctuation of power

supply voltage shall not exceed 380V± 15%.

After correctly connecting the wires, close the circuit. Start, oil pressure is normal.

Parameters Working voltage: SH-YT-300 (500800) external 380V, three wire four wire AC power supply. The neutral line must

be connected.

Set the relevant pressure data for the wire rope pressure head.

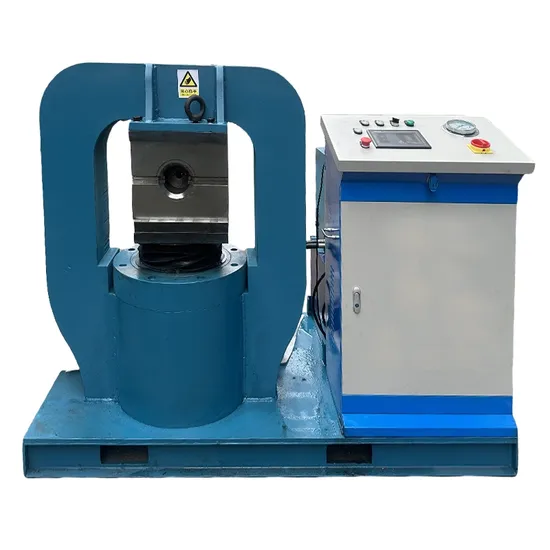

Operating procedures This pressing machine is mainly designed for steel wire rope pressing heads. Solved the problem of high manual

insertion and weaving intensity in the past, and improved production efficiency and safety. Enterprises, workshops,

processing workshops, storefront operations, and other places can all be used.

After setting the relevant parameters, start the equipment and the oil pressure is normal. Put the steel wire rope into

the sleeve and put it into the mold. The foot switch controls the stroke of the oil cyinder for compression molding.

Easy to operate, convenient for one person to work, time-saving and labor-saving.

Faults and alarms

ln case of emergency, press the emergency stop button to stop the machine. The equipment has various safety protection measures such as overvoltage, overcurrent, overload, overheating,

undervoltage, and undervoltage.

Security and Maintenance During the work process, it is important to coordinate the running speed well. Avoid safety accidents caused by

high-speed operation.

Do not overload the operation to avoid damaging the equipment or burning out the motor and electrical

components.

Regularly clamp lubricat ing oil on the gearbox and observe the temperature rise and noise of the motor. If the

temperature rise exceeds 85 degrees, stop the machine for inspection.

>>

2022 Adjustable hand grips 1 unidad premium 2011 gsxr hand grips expander for hands finger trainer

>>

foam shredder/Foam crusher machine/Plastic crusher machine

>>

High Pure Magnesium Ingot Alloy at a Competitive Price

>>

808 Diode Laser Hair Removal 755 808 1064 Laser Diode Alma Ice Titanium

>>

Quality Used Injection Blow Molding Machines for Efficient Production

>>

12V30ah Intelligent Gel Mf Maintenance Factory Activated Power Sports High Performance Rechargeable Bike Lead Acid Motorcycle Battery

>>

Poultry Farm Equipment Silo with Competitive Price Corn and Wheat Grain Silo

>>

Replacement Anti-slip Racket Overgrips Over Grips 110cm Pickleball Paddle Tape Grips

>>

Cheapest Reel Monofilament Fishing Line 100% Fluorocarbon Fishing Line

>>

High Quality Refractory Infrared Propane Gas Stainless Steel Chicken House Poultry Gas Brooder Heater

>>

Asttar 60 Minutes CE Certified Oxygen self rescue Pack oxygen Self Rescuer

>>

Synthetic Quartz Absorption Cuvettes Absorptiometer UV Quartz Glass Cuvette

>>

Customized tuna fish processing plant with high quality

>>

Chine Manufacture Pad Kraft Fill Making Cushion Void Paper Bubble Making Machine

>>

220V Pellet Press for Making Pellets

>>

Precision Titanium Material Factory Supplier Medical Titanium Bar with ASTM F136

>>

Dh48j Infrared Counter Relay Counter Electronic Digital Display Induction, with Power Outage Memory

>>

Pinbo Wheat Fibre Flying Disc

>>

Full Automatic Dsiposable Aluminum Foil Cardboard Paperboard Paper Plate Tray Forming Machine

>>

Downhole Navigation System Gyro Inclinometer North Seeking Continuous Fiber Optics Gyro for Deep Oil/Gas Logging