Basic Info.

Shaping Mode

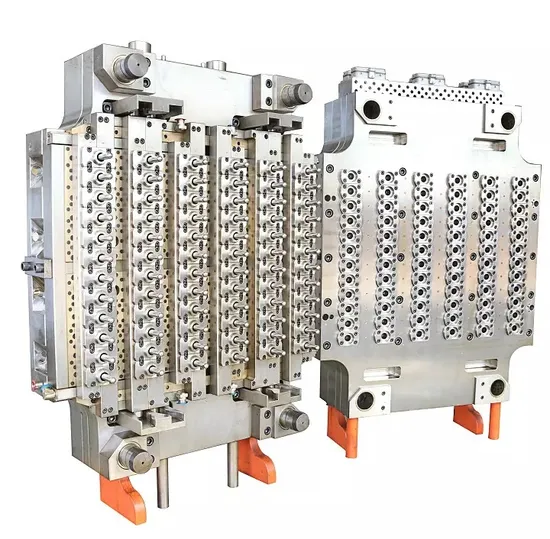

Injection Mould

After-sales Service

Video Technical Support

Mold Plate

P20 Steel S136 Steel H13 Steel

Mold Life Time

3-5 Million Shots

After -Warranty Service

Online Support

Transport Package

Wooden Case

Packaging & Delivery

Package Size

80.00cm * 30.00cm * 40.00cm

Package Gross Weight

200.000kg

Product Description

Product Name and Plastic PET preform mold core cavity lip cavity neck thread making

Core & Cavity Steel :

2316#steel,S136 stainless steel or based on customer's requirement.

Mould base & Standard Component :

DME,HASCO,MISUMI,LKM,Self-made with P20, 3CR13, 4CR13 material etc.

Steel hardness :

HRC30-35 for base material.

HRC45-48 for core and cavity material.

HRC60-62 for special parts material

Plastic material :

PET, PP, ABS, PC, AS, TRITAN etc.

Cavity Number :

1*4, 1*6, 1*8, 1*12, 1*16, 1*24, 1*32, 1*48 etc

Injection System :

Pnuematic Valve gate with shut off & free-cut or short tail or long tail etc

Ejector System :

Mould slider + Stripper plate ejection

PET preform Mold Feature

1. Mold plates are P20 steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mold plate is completed by one-time processing to ensure the concentricity of molding hole and guide bush, guaranteeing the compact structure of mold.

2. Spiral cooling design for each single core and cavity, it helps to lessen the cycle time, improving production efficiency and savign costs. Opening/closing pulling plate adopts bearing slide type to drop the preform with realiable structure.And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction effecient and strong wear-resistant.

3. Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production and also convenient disassembly.

4. Off-center adjustment system to ensure preform thickness difference < 0.10mm. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product without appearing flash, different size, irregular and other defects.

5. Experienced designers design preform mold with the help of computer according to the final bottle shape; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

6. Hot runner valve gate is available; No need to cut preform tail and it would save labor costs. Standard inter-changeable mold components for easier replacement.

7. Hot runner system: China advanced brand or imported hot runner system brand such as Yudo/Mastip/Hasco etc.Each cavity has independent temperature control and heater system.It will prevent the white defects on the preform and improve the qualtiy of plastic products. Advanced hot runner system assures lower level of AA value.

8. Customer service: one year free warranty, life-long technical support service.

| Mold | 24 48 72 cavity PET Preform Mold Can Be Customized |

| Preform Neck | 28mm,30mm |

| Preform Weight | Customized |

| Runner | Hot Runner |

| Core Material | S136 |

| Cavity Material | S136 |

| Screw Neck Material | S136 |

| Mold Base | 4CR13 Steel |

| Mold Life | 5 millions |

| scope of Application | Water bottle |

| Delivery time | 60-70 days |

------Our Partner------

------AFQ------

Q1 :What kinds of product you supply?

A1: Sticker Labeling Machine,Shrink Sleeves Labeling Machine, Shrink Wrapping Machine, Injection Molding Machine, Blowing Machine, Filling Machine, Packaging Machine, Plastic Products, etc.

Q2: How to tell your enquiry?

A2: Contact us by email,phone call, fax,instant Messenger (Trade manager , Whats app, Skype) and let us know your inquiry.

Q3: How to choose suitable machine?

A3: Tell us your requirement, and we will advise you.

Q4: Do you have technical support after we purchased your machine?

A4: - We will provide video technical support,online support.

- If you need,we can also arrange our professional technical to go aboard to your factory,they will help and teach you how to install and maintenance the machine.

>>

Wholesale cheap price Auto ac Compressor for JOHN DEERE TPΑΚΤΕΡ Full 24V DCP99523

>>

Semi-Automatic Sample Loom with PLC control touch and USB interface to share designed patters

>>

Automatic Feeding Fiber Laser Cutting Machine for Pipe Tube

>>

Plastic PVC Cable Granulating Machine

>>

Best Selling Stable Working Performance Poultry Feed Rabbit Feed Pellet Mill Machine

>>

Sialwings Premium Custom Softshell Jacket Best Selling Waterproof Jacket Outdoor Running Jacket super soft materials

>>

Chinese products medical appliance invisible hearing aids for sale

>>

New Arrivals High Quality Slim Fit Denim Pant Cotton Amiry Jeans Distressed Wash Highstreet Ripped Purple Men′s Jeans D2

>>

250HP 60HP 190HP 300HP 150HP Agricultural Tractor Loader Fuel-Efficient Combustion Trenching Tractor Rear-Mounted Mower Deck Ready Terrain-Responsive

>>

HC-W024 Mindray spare parts BS200 220 300 320 330 350 Biochemical analyzer filter 578NM 630NM 670NM indray accessory

>>

Automatic plastic bag pillow packing machine sponge scourer/ scouring pad horizontal wrapping machine

>>

Custom Sexy Adjustable Invisible Zipper Sports Bras Women High Impact Backless Yoga Tops

>>

Walking Tractor Cultivator: Mini Power Tiller for Easy Farming

>>

Hot Sale Custom 100% Virgin grade Diameter 4mm to 300mm Moulding Cutting PTFE Rods

>>

3D Wood Carving CNC Router 1325 Atc Cabinet Furniture Door Engraving Hinge Drilling Machine

>>

sliced almond almond chocolate shelled almonds

>>

price polypropylene PP laminated plastic valve block bottom empty cement bag 50kg 25kg with Kraft paper inside liner

>>

Juli Flat Polyester Webbing Industrial Sling Ribbon Lifting Belt Sling

>>

Single Jet Class B with Pulse Output Water Meter

>>

6ES7315-2AG10-0AB0Siemens S7-300, CPU 315-2DP CPU with MPI