Product Description

Product Description

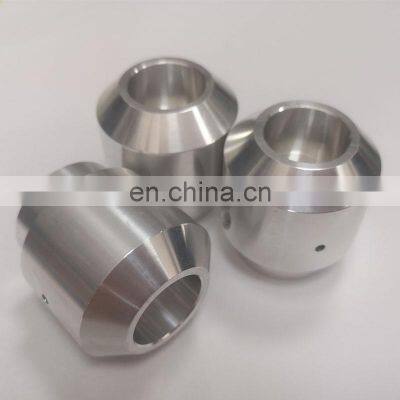

Products DescriptionProduct namePrecision Oem Cnc Machining Aluminum Parts Top MountingMaterialiron ,steel,aluminum,brassProcesssand casting,die castingMachiningCNC machiningServiceOEM /ODM CustomizedDetails ImagesMaterial:The material conforms to the industry standard.quality is assured.3-AXIS MACHININGThese are the most common CNC machines produced commercially. They can move in the X, Y and Z axes simultaneously. The most common size of the 3 axis machine is one with a work table of 40x20 inches. Work performed on 3-axis machine can be simple prismatic parts, all the way to complex molds, medical or aerospace parts.Surface:Smooth surface, no burr, no sharp Angle4-AXIS SIMULTANEOUSThe difference in 3+1 and 4-axis simultaneous is that the part can rotate on one axis at the same time it is milling in 3-axis.This type of machining is necessary when part geometry wraps around a part, common in the aerospace and other industries. While all 4-axis simultaneous milling machines can perform 3+1 axis milling, not all 3+1 axis mills can do 4-axis simultaneous. One needs to make sure of their machine’s capabilities before trying to run a program it may not support.Customization:Can be customized according to customer drawing and provide samples.5-AXIS MACHININGThis type of machining allows for the most flexibility in milling the part at different tool orientations. Here, the part canrotate in two separate axes, usually A&C or B&C, at the same time the 3 linear axes are moving. Machining in simultaneous 5-axis is popular in parts where complex shapes, and small clearances, are the norm; such as impellers, turbines, intake ports and more.True simultaneous 5-axis machines can run in all the previous modes; 3-axis, 3+1 axis, 3+2 axis, 4-axis simultaneous plus 5-axis simultaneous. While all 5-axis simultaneous machines can perform 3+2 axis machining, not all 3+2 axis machines can do 5-axis simultaneous. It is a function of the machine’s design and the CNC controller installed. These mills are typically more expensive than the other mill types, for the same size, but offer the most flexibility when setting up your jobsRelated ProductsCustomer ReviewManufacturing TechniqueFactory IntroductionCertificationsPacking & Deliverly

>>

shacman Foton QSM11 split steel piston 3804885 3804980 3806219 3806270 3923164 3957799 3957801 4024941 4025072

>>

Strongflex W. P. 150 Psi (10Bar) Industrial Rubber Tank Truck Oil Hose

>>

Customized Metal Wood Chipper Blades for Woodworking Industry

>>

20ft Container Lowbed Trailer ,FUWA/BPM 13/16/20 TON 3-Axle from China

>>

High Speed Automatic Roll Paper Label Cutting Machine with Slitting function Max working width 500mm

>>

PDD200A101 ABB module inventory spot sale

>>

Interior Decoration Carved Wood Corbel

>>

Laminated Glass Decorative Wire Mesh Screen factory

>>

S. S. Precision Electronic Platform Scale

>>

Customized/OEM Aluminum Alloy Camera Cover Box with High Precision

>>

High Quality Custom Experienced OEM Service High Precision Plastic Injection Molding Manufacturer

>>

Customized Straight Line Wire Drawing Machine for Stainless, Carbon, and Copper

>>

Factory price green banana peeling machine/banana peeling machine/plantain peeler machine

>>

Vibration Molding Concrete Making Machine Fully Automatic Block Production Line

>>

Small Iron Bucket Fertilizer Applicator/Spreader

>>

Hot Press Machine Rubber Vulcanizing Press Machine Vulcanizer

>>

Compact Hose Crimping Machine Hydraulic 1/4′′--2′′ Hose Coupling Machine

>>

Excellent Quality Self-Lock Nut Prevailing Torqu Funts Stainless Steel Bearing Lock Fine U Nut

>>

2024 Fiber Metal Laser Cutter for Sale 1000W 2000W 3000W

>>

Liugong Excavator Hydraulic Crawler Digger Mini 1.9t Excavator 9018f Best Price