Product Description

Product Description

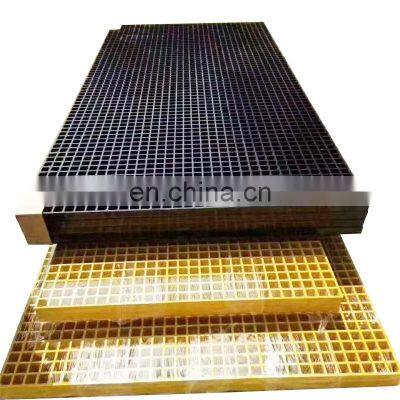

Product Descriptiongood price water treatment industry molded FRP grating platformFiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs.---Strong, Lightweight and Corrosion-ResistantMolded FRP Grating has the strength of steel, but it won’t corrode like steel can.---Safer Walking Surface for Trench Covers and Fiberglass WalkwaysA coarse, gritted epoxy coating enhances traction.---Support and StabilityMolded Fiberglass Grating Panels are equally strong in both directions---Easy FabricationFRP Flooring Panels are lightweight, easy to transport, and can be cut and fabricated using standard hand tools.---Extended LifeThe coated resin surface increases resistance to chemical corrosion and continuous UV exposure.Material advantages:Strong bearing capacityStretch-proofHigh-temperature resistanceAnti-corrosionNon-flammableGood insulationNo rustNon-slipMildewproofAnti-shrinkageEasy to cutEnvironmental protectionSpecification Fiberglass Grating has many sizes for you to choose.ThicknessmmMesh SizemmPanel SizemmOpen Area%Unit Weightkg4040*401007*300764602538*381220*366069523838*381220*366069855050*501220*3660721003038*381000*04069753825*1521145*290060763025*251220*3660648450*503819*191007*4007729238*38Production steps for FRP grating:1. Stirring raw materialsResin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20 minutes.2 . Draw yarnLay the alkali-free yarn layer by layer to improve the strength of the FRP grating.3 . Compression moldThe stirred raw materials are poured into the mold and compacted mechanically or manually.4 . Heat curingAfter the grating is heated for 20 minutes, the raw materials and yarn are fused together.5 . Cooling demoulding, mold liftingAfter the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.6 . Grinding, painting and washingThe FRP grating is polished and washed with a layer of varnish or water.PackingConstructionGuardrails, stairs, ladders, wall gratings, platforms, etc.Drainage treatmentDrainage ditch, drain grating, platform, structure, etc.Civil EngineeringFloors, sidewalks, bridges, tree protection, car washes, parking lots, Protect grating, etc.Chemical IndustryWork platform etc.Food processing and aquacultureThe platform, engineering guardrail, etc.Ocean industryPlatforms, fencing, sidewalks, etc.Details ImagesMolded FRP grating is composed of alternating directional layers of continuous glass fiber for strength, with resin to consolidate the fibers and provide the shape and corrosion-resistance. Molded grating has very high impact tolerance, as well as the highest chemical resistance of any fiberglass grating. It can be made slip-resistant by adding grit to the surface.Fiberglass grating accessories: M-type,S-type,C-type.Product packaging Fiberglass Grating is usually packed by the pallet. To protect the FRP grating in good Condition, We must pack them on pallets, with Corner Guard protect, and film wrap.FAQQ: How can you guarantee your product quality?A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high quality supplier.Q: Are you a trading company or a manufacturing factory?A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China since 2010.We have FRP products of high quality and various kinds.Q: I am interested in your products, could I get sample for free?A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping account.Q: Can you do the design for us?A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customized shape,dimension, colors service.For more details, no hesitant to contact me.

>>

Greetmed High quality hospital adjustable electric bed

>>

Water Proof Disposable Plastic Pp Cpe Medical Boot Shoe Covers Disposable Non Slip

>>

Windproof Sunshade Slats Aluminum Shutter Window

>>

Vacuum Sealer Machine Food Meat Fruit Vegetable Vacuum Packing Paper Packaging Material

>>

High Voltage Power Line Lightning Protection Suspension Type 10kv Polymer Insulator

>>

For AUDI Auto Engine Timing Chain Tensioner Car Engine 06E109217A 06E109217H TN1505-2

>>

2021 Shangtao The New Yarn Guide Textile Ceramic

>>

Colorful children indoor plastic slide and swing playground toys equipment for sale

>>

Interior Decoration Aluminum Expanded Metal Mesh for Ceiling Tiles

>>

Diamond Saw Blade Granite Marble Cutting Disc Porcelain Tile Ceramic Blades

>>

Punching Finger for PVC PU Conveyor Belt

>>

Mini Small Plastic Tomato Sauce Squeeze Ketchup Bottle Product Picture Real Shot IBM35/45/65/75 Injection Blow Moulding Molding Machine of Long Service Life

>>

Hot Sell Pre-Made Brochure Display Stand for A4 Magazine Display Racks Brochure Holders Brochure Floor Stands

>>

Solarthon Hybrid Solar Power Inverter 1.6kw 3kw 3.5kw 5.5kw on off-Grid Home Energy Storage Solar System Pure Sine Wave Combined with CE RoHS Certificate

>>

Roll to Roll Slitting Machine Cutting Machine

>>

Rubber Oil Seal Gasket Cutting Machine

>>

Wd615/Wd10 Made in China Marine Diesel Engine with Gearbox Cheap Price 300-400HP

>>

Waste Plastic Film Recycling Machine

>>

High Precision Affordable Woodworking CNC Router Machine for Wooden Furniture

>>

1gallon Plastic Bottle Making Machine