|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

5450*2210*2100

Production Capacity

1000/Year

Product Description

Product Description

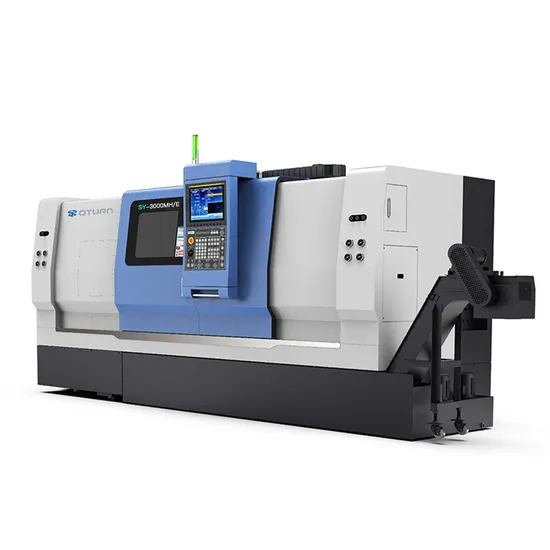

This High Precision CNC Lathe Machine with Live Tooling boasts an optimized 30-degree inclined bed structure, ensuring high precision, exceptional rigidity, and superb cutting stability. Constructed from high-strength HT300 cast iron with a one-piece, robust bed structure, it employs finite element analysis to deliver outstanding mechanical rigidity and stability. This ensures long-term reliable precision, enhanced processing stability, and extended tool life. Stress relief treatment further enhances precision stability. The high-strength hard rail structure, combined with a screw pre-tensioning design in the transmission system, significantly boosts rigidity performance. Main features of this machine tool: 1. The spindle unit features an independent sleeve design and has undergone rigorous dynamic balance tests, ensuring high precision, excellent precision retention, minimal thermal deformation, and superior thermal stability. It achieves a maximum speed of 2500rpm with a nose deflection accuracy within 0.003MM. The spindle's front end integrates a large-diameter, high-precision double-row roller bearing with a combined oblique contact ball bearing structure. The optimal two-point balanced support design withstands radial and axial loads, making it ideal for both high-speed precision cutting and low-speed heavy cutting. This is especially suitable for mass production of complex, high-precision, and high-finish products. 2. The machine features a high-rigidity servo power turret, facilitating rapid and precise tool changes. Coupled with high-speed power shaft milling, it ensures excellent turning and milling capabilities. The tool holder is equipped with a high-rigidity BMT installation interface, and the power transmission shaft is servo spindle motor-driven. 3. Equipped with hard rail guide rails and precision-ground ball screws, the machine guarantees optimal precision and durability. Each axis employs a direct transfer axis structure and a double-anchor pre-relay method, minimizing thermal displacement and significantly improving machining accuracy. The precision-ground ball screws ensure exceptional precision and extended durability. Each axis uses a direct transfer axis structure with a double-anchor pre-relay method, reducing thermal displacement and greatly enhancing machining accuracy. 4. The machine features a comprehensive hydraulic and lubrication system, utilizing high-quality hydraulic pumps, valves, and other components, which significantly reduce failure rates. Its hydraulic and lubrication system is designed for simplicity and reliability, with centralized quantitative automatic lubrication. 5. The hydraulic tailstock boasts a high-rigidity integral structure that eliminates vibration and offers exceptional stability. Sleeve expansion and contraction are controlled by a hydraulic cylinder, ensuring convenience, speed, and reliability. 6. Featuring a Taiwan rotary chuck oil cylinder and an automatic chip removal device, this machine greatly reduces operator labor intensity while ensuring safe and efficient production. All functional components can be controlled via programming, including special fixtures.

Product Parameters

| Name | Unit | SY3000MH/E |

| Max. swing diameter over bed | mm | Φ640 |

| Max. processing diameter | mm | Φ460 |

| Max. swing diameter over cross slide | mm | Ф350 |

| Max. processing length | mm | 3250 |

| Spindle nose | / | A2-15 |

| Chuck | " | 15 |

| Spindle bore diameter | mm | Ф132 |

| Bar diameter | mm | Ф117 |

| Max. spindle speed | rpm | 1500 |

| Spindle motor power | kw | 26KW |

| Motor torque 248 pulley ratio; 1:2 | Nm | 496/706 |

| X/Z travel | mm | 280/3310 |

| X/Z Specification of shaft guide | | Box way |

| X/Z Shaft motor torque | Nm | 18.6 |

| X/Z motor power | KW | 2.9/2.9 |

| X/Z axis moving fast | m/min | 18/18 |

| Positioning accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 |

| Power turret | / | BMT65-12T/ER32 |

| Power turret motor | Kw | 5.0/7.5 |

| Max speed of power turret | Rpm | 5000 |

| The specification of outer diameter tool holder | mm | 25x25 |

| The specification of inner diameter tool holder | mm | Ф50 |

| The adjacent tool change time | sec | 0.2 |

| Programmable hydraulic tail seat | | Hydraulic |

| The biggest stroke of the tail | mm | 3180 |

| Morse Slideway | type | Mosh5# |

| Sleeve diameter | mm | Ф100 |

| Sleeve travel | mm | 80 |

| Machine size | m | 9700*2350*2200 |

| Machine Weight | kg | 12500 |

| Cutting fluid tank volume | L | 250 |

| Cutting water pump | kw | 0.75 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic oil pump motor power | kw | 1.5 |

| Lubricant tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

| Cooling water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1: How can I choose the most suitable machines?

Please provide your specifications, and we will recommend the ideal model for you. Alternatively, you can select a specific model, or send us your product drawings, and we will ensure you get the most suitable machine.

Q2: What are the main products of your company?

We specialize in a wide range of machinery, including CNC Lathe Machines, CNC Milling Machines, CNC Turning Machines, Vertical Machining Centers, Horizontal Machining Centers, Lathe Machines, and advanced turning and milling composite processing systems.

Q3: Where is your factory located, and how can I visit?

Our facilities are located in Guangzhou, Quzhou, Ningbo, and Guangdong. We warmly welcome you to visit any of our 5 factories.

Q4: How do you handle transportation?

We provide comprehensive transportation solutions including DDP, CIF, FOB, and FCA.

Q5: What are the payment terms?

Our payment terms are T/T, with a 30% initial payment upon order and a 70% balance payment before shipment.

Q6: What's the Minimum Order Quantity (MOQ)?

A: The MOQ is 1 set. However, for some lower-cost machines, the MOQ may be more than 1 set.

We want to know:

1. We strongly suggest providing the size and material of your workpiece for our evaluation. It's even better if you can send us the workpiece drawing, so we can recommend the most suitable model.

2. If you need a CIF price, please kindly inform us of your port of destination.

>>

120kw 150kVA Boat Ship Marine Engine Drive Diesel Generator Set

>>

0.5tph Chicken Manure Dryer Machine

>>

6ES7223-1HF22-0XA8SiemensSIMATIC S7-200 CN digital module I/O EM 223 for the S7-223CPU

>>

CNC Lathe with Flat Bed Factory Price Cfk6180b Cfk6180d Cfk6180q

>>

hot sale brand new 450hp/2100rpm 6 Cylinders Sinotruk D1242C Series Marine Diesel boat Engines D12.45C01

>>

Customised Small Baby Clothes Hanger and Clip

>>

Youzi Topper Silk Lace Base Human Hair Topper for Women Russian Human Hair Toupee Double Drawn Cuticle Aligned Stock Ready to Ship

>>

Vacuum Lotion Shampoo Homogenizer Emulsifying Emulsifier Mixer Machine Skincare Cosmetic Cream Toothpaste Making Machine

>>

Auto parts car front bumper mold plastic injection mold

>>

Personal/Human Electrostatic/Anti-Static Eliminator Device to Discharge Electrostatic From Human

>>

Popular New Design Good Quality Zinc Alloy Door Handle

>>

Efficient Plastic Recycling Pyrolysis Diesel Plastic Pyrolysis Plant

>>

Gaming Laptop 15.6inches I7 CPU Notebook

>>

Handheld Pocket Size LCD Display Digital Multimeter with Ce RoHS

>>

Farm Tractor 3 Point Hitch Disc Harrow

>>

Wheat Paddy Sorghum Combine Harvester Cag-2000b

>>

Ahyw Electric Sheet Metal Bending Machine Stainless Steel Plate

>>

New Design Home Use Vacuum Freezing Dryer Machine for Candy Skittles Instant Coffee Fruit Freeze Drying

>>

75um Dual-Silicon for Printing Die Cutting Punching Processing Blue Pet Release Film

>>

Pet Bottle Washing Drying Recycling Machine Line