|

US$50,000.00-200,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Linear Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Machine Size

2200*1700*4000

Transport Package

Wooden Case

Specification

2200*1700*4000

Packaging & Delivery

Package Size

3500.00cm * 3000.00cm * 5000.00cm

Package Gross Weight

100000.000kg

Product Description

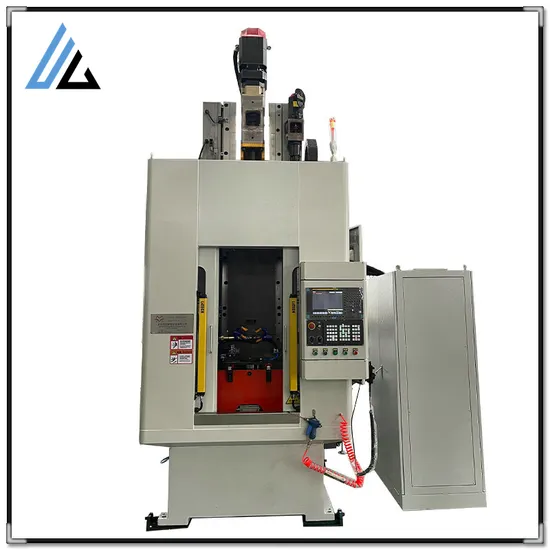

Vertical Broaching Machine For Metal-Cutting CNC Machine Tools The pull-down inner broaching machine tool is a vertical inner broaching machine with a semi-protected and fully escorted structure. The auxiliary slide plate is installed on the main slide plate. When the machine tool is working, the clamping device on the main and auxiliary slide plates simultaneously locks the front and rear tool handles of the broach. Provide effective support to ensure that the broach is fixed during the working process and there is no displacement at both ends. The workpiece to be processed is fixed on the workbench after self-centering. The broach moves downward. After broaching is completed, the material is unloaded and returned. , the fully escorted broaching method effectively ensures the accuracy and stability of the parts being processed. The installation methods of this equipment are divided into ground installation and buried installation.

This type of machine tool is suitable for processing various types of internal gears, internal splines, and inner holes of geometric shapes. The machine tool adopts hydraulic transmission and has stepless speed regulation through the human-machine interface. It can be divided into three types: fully automatic cycle mode, semi-automatic segmentation, and manual adjustment. operating mode. The machine tool is equipped with automatic tool adjustment function.

The machine tool can be equipped with optional automatic loading and unloading devices (truss manipulator or joint robot), which greatly reduces the operator's labor intensity and improves the quality and quantity of parts processing.

Product Description

Product Parameters

| Rated force x Rated Trave | 150kN x 1200 mm |

| Broaching speed(continuously viable) | 0-80 m/min |

| Return speed(continuously viable) | 0-80 m/min |

| Tooth profile precision | 5 grade |

| Surface roughness | Ra1.6-0.8 |

Company Profile

Sunrise Mechatronic Technology Co., Ltd. is a professional enterprise engaged in research and development and manufacture of metal process machinery for more than 15 years. As a dynamic player in the machine tool industry, we take pride in our unique 'industry and trade integration' model, offering a holistic approach to meet diverse manufacturing and supply chain needs.

Integrated Manufacturing & Trade:

Our innovative model allows us to seamlessly integrate manufacturing excellence with efficient trade solutions. From the creation of advanced machine tools to their timely delivery to clients, we manage the entire process to ensure quality and reliability.

Product Portfolio:

Explore our comprehensive range of machine tools designed to cater to diverse industries. From CNC machining centers to precision lathes, our products are crafted with precision, reliability, and advanced technology at their core.

Customization & Flexibility:

Understanding that every client has unique needs, we offer customization options to tailor our machine tools according to specific requirements. This flexibility sets us apart, ensuring that our solutions align perfectly with our clients' manufacturing goals.

Certifications

FAQ

Q:What's your payment terms?

A:T/T,L/C,Paypal,Western Union etc.

Q:How long is the product warranty?

A: 24 months

Q: Are you a trading company or a manufacturer?

A: We are a professional manufacturer. Our products have been exported to Asia, South America, Africa, and have developed a good world wide reputation.

Q: What kind of product certification do you have?

A: All our products have passed ISO9001 and CE certifications. We have strict quality inspection process before leaving our factory in order to offer the best quality machines to our customers.

Q: Do you have after sales service?

A: Yes, we have special service team which will offer you professional guidance, or On-site installation in customer Factory.

Q: Do you test all your goods before delivery?

A: Yes, we have strict quality inspection process including a load test for every machine before leaving our factory.

>>

Colorful Metal Eye Button Faucet Farm Horse Halters

>>

Durable and Weather-Resistant Basketball Backboard

>>

high quality breather hose for E60 E65 E66 E70 OEM 11617563477

>>

Bowling Ball Toy Kids Set Large Indoor Ball

>>

High Performance Hot Selling Portable Digging 1.8ton 2.2ton Heated Cabin Construction Equipment Digging Machine Mini Excavator for Sale

>>

Fully Automatic CZ Purlin Roll Forming Machine

>>

Wired Door/Window Magnetic Contact (TA-32)

>>

Combined Harvester Machine for Rice Small Rice Harvesting Machine Price

>>

Original Scooter Part Rear Fork Assy for Sh125

>>

Fabric Tensile Strength Tester Micro-Computer Single Column Electric Universal Testing Machine

>>

Jinmao Textile Machine High Speed High Precision Short Running In Long Life Spinning Machine BS JM1 EM gc 4# Series Ring Traveller

>>

New Powerful Engine Professional Cultivator 50.8cc

>>

Floral Flavor Concentrated Laundry Liquid Detergent for Automatic Washing Machine for America and Canada Market

>>

Taijia Concrete crack width detector crack depth gauge crack depth detector

>>

#12 meat grinder mincer chopper plates knives Sausage Stuffer Plate

>>

Paddy Corn Sorghum Combine Harvester Cag-2000b Farm Machinery Hot Sale

>>

200W 300W Cleaner Laser Cleaning Machine Metal Paint Removal with Good Price

>>

China Engineered Hardwood Flooring Manufacturer

>>

China Bus Accessories Front Windshield Laminated Glass (B413, white, without lane radar) 5302-10440 White Laminated Glass 4+0.76+4 for Yutong Zhongtong Bus

>>

Radial Drilling Machine Z3040X14/1 with CE