| US$26,000.00 | 1 SET (MOQ) |

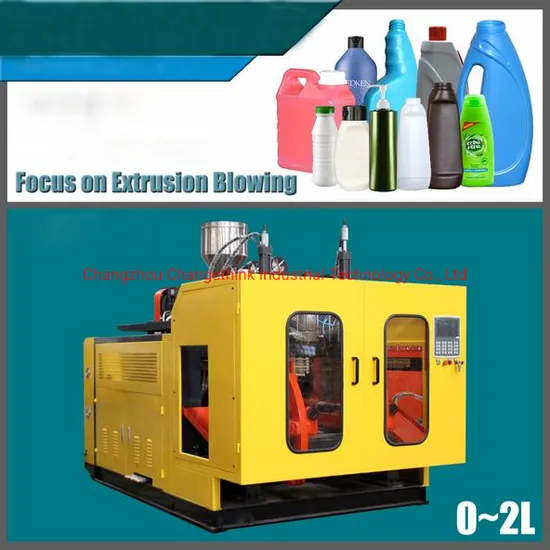

| 1 | LTY55D-2 is double station double head EBM machine specially for 0~1L products. |

| 2 | The output for 500ml round bottle is 600 BPH, the daily output is about 14400 bottles. |

| 3 | High efficiency extrusion system is generally suitable for LDPE, HDPE and PP. |

| 4 | Adopt nether bent arm clamping structure guided with linear rails for double direction. |

| 5 | With two pneumatic cylinder for head lifting in balance, clean & easy for maintenance. |

| 6 | Optimized hydraulic system & mechanical shuttle cylinder for platen moving stability. |

| 7 | Lubrication system, product clamping boards and scraps slide channels are included. |

| COMPONENTS | BRAND | ORIGIN |

| PLC | MITSUBISHI | JAPAN |

| TEMPERATURE CONTROL MODELS | HONGGE | TAIWAN |

| COLORFUL TOUCH SCREEN | WEINVIEW | TAIWAN |

| CONTRACTOR | SCHNEIDER | FRANCE/CHINA |

| AIR SWITCH | SCHNEIDER | FRANCE/CHINA |

| MID RELAY | OMRON | JAPAN |

| PROXIMITY SWITCH | RIKO | TAIWAN |

| INVERTER | DELTA | TAIWAN |

| OIL FILTER | DONGFANG | CHINA |

| OIL TUBE & JOINT | PACKER | U.S.A. |

| SEAL PARTS | DZ | TAIWAN |

| HYDRAULIC PUMP | HYTEK | TAIWAN |

| HYDRAULIC VALVE | HYTEK | TAIWAN |

| PNEUMATIC VALVE & CYLINDER | AIRTAC | TAIWAN |

| COMPRESSED AIR FILTER | AIRTAC | TAIWAN |

| LINEAR GUIDE RAILS | HIWIN | TAIWAN |

| HARD GEAR BOX | HAOKE | CHINA |

| HYDRAULIC PUMP MOTOR | SIEMENS BEIDE | CHINA |

| EXTRUSION MOTOR | SIEMENS BEIDE | CHINA |

| SPECIFICATIOIN | /PARAMETER | ||||

| Machine Model | Double Station Double Head | ||||

| Max Product Volume | 1000 ML | ||||

| Dry Cycle Time | 4.5 Second | ||||

| Pre-heating Time | 1.5~2.0 Hours | ||||

| Machine Weight | 4.5 Tons | ||||

| Machine Size | 3.2*2.1*2.3 m | ||||

| /EXTRUSION UNIT | |||||

| Screw Diameter | 55 mm | ||||

| Length/Diameter Ratio | 24:1 | ||||

| Heating Zone No. | 3 | ||||

| Heating Power | 11.6 KW | ||||

| Cooling Fan No. | 3 | ||||

| Fan Power | 0.15 KW*3 | ||||

| Extrusion Motor Power | 15 KW | ||||

| Plasticizing Capacity | 65 Kg | ||||

| /CLAMPING UNIT | |||||

| Clamping Force | 56 KN | ||||

| Platen Size | 290*360 mm | ||||

| Platen Moving Distance | 375 mm | ||||

| Platen Opening Stroke | 130-380 mm | ||||

| Max Mould Size | 310*360 mm | ||||

| Mould Thickness | 135-230 mm | ||||

| /HEAD UNIT | |||||

| Head Type | Continuous Extrusion Head | ||||

| Head No. | 1 | 2 | 3 | 4 | |

| Central Distance/mm | - | 130 | 90 | 75 | |

| Max Die Diameter/mm | 110 | 60 | 35 | 25 | |

| Heating Zone No. | 2 | 3 | 4 | 5 | |

| Heating Power/KW | 4.2 | 3.3 | 4.2 | 6 | |

| /ENERGY CONSUMPTION | |||||

| Extrusion Motor Power | 15 KW | ||||

| Oil Pump Motor Power | 5.5 KW | ||||

| Extrusion Heating Power | 11.6 KW | ||||

| Head Heating Power | 4.2 KW | ||||

| Cooling Fan Power | 0.45 KW | ||||

| Total Power | 36.68 KW | ||||

| Average Energy Consumption | 21.5 KW | ||||

| /REFERENCE | |||||

| Cold Water Needed | 0.3 Mpa | 3500 L/h | |||

| Compressed Air Needed | 0.6 Mpa | 0.6 M3/min | |||

| Installation Capacity | 100 Amp, 3*25 m+ 1*16 m | ||||

| Loading Reference | 20' GP*1 | ||||