|

US$3.00-4.00

|

10 Pieces

(MOQ)

|

Basic Info.

Certification

CE, RoHS, GS, ISO9001

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Die Casting Machine Type

Hot Die Casting

Surface Treatment

Plating

Tolerance

+/-0.01mm, 100% QC Quality Inspection

Price

Negotiable as Per Request

Quality Assurance (QA)

Coordinate Measuring Machine (CMM)

Production Shape

Various Shapes Are Available

Areas of Application

Hardware Machinery,Electronic Accessories

Quality Control

100% Inspection

Transport Package

Pallets/Wooden Crates/Air/Sea Transportation

Production Capacity

10000 Pieces/Month, 800 Tons/Year

Packaging & Delivery

Package Size

120.00cm * 80.00cm * 70.00cm

Package Gross Weight

400.000kg

Product Description

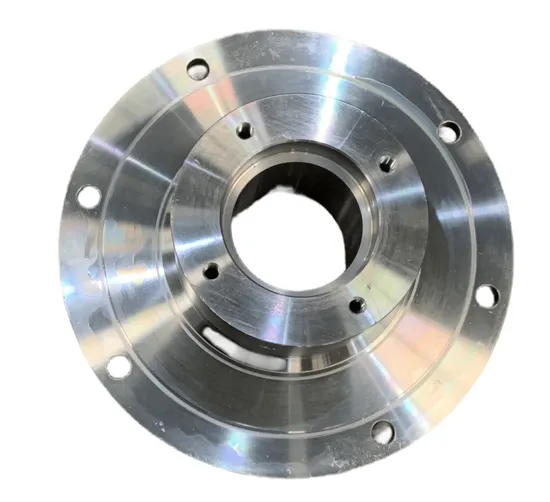

High Demand Precision CNC Bar Tubing Hardware Manufacture Cusyomized Alloy Aluminum Steel Metal Components Equipment Accessories Die Cast Spare Machinery Parts Product Parameters

| Item name | Stamping parts |

| Trademark | KRD |

| Place of Origin | Qingdao, China |

| Model NO. | Custom Made |

| MOQ | 100 pcs |

| Production Shape | Various shapes are available |

| Material | Aluminum,Aluminum Alloy,Zinc Alloy,Alloy,Copper Alloy,Stainless Steel,etc. |

| Specification | OEM/ODM, as per client' s drawing or sample |

| Tolerance | +/-0.01mm,as per customers' requirement |

| Surface Treatment | Polishing,Spray Coating,Deburring,Electroplating,Oxygenation,Baking paint,Grind,Oil Blooming,Blackening Process |

| Package | Serving Tray/Wooden Box or as customer's requirements |

| Application | Machine Part,Hardware Machinery,Electronic Accessories,Agricultural Machinery Parts,Equipment Accessories,Auto Parts |

| OEM ODM Service | Yes |

| Business Type | OEM& ODM Manufacturer (Custom CNC Machining Services) |

| Quality Control | 100% Inspection |

Product Images

Installation Instructions

This product is a high-precision machined part, using high quality materials and advanced processing technology, with excellent strength, wear resistance and corrosion resistance, suitable for a variety of applications in various fields, such as photovoltaic cutting equipment, machine tools, construction machinery and agricultural machinery.

The products are designed and manufactured by Qingdao Krede Machinery Manufacturing Co., Ltd. with strict implementation of quality management system to ensure that each part meets the strict technical requirements of customers.

The products use advanced CNC machine tools to ensure the dimensional accuracy and surface finish of the parts. Supporting a wide range of material processing, including aluminum alloy, stainless steel, carbon steel, copper alloy, etc., to meet different industrial needs. Integrating casting, forging, welding, milling and wire-cutting, we can provide customized solutions according to customers' needs.

We always follow the principle of "quality first, customer first", and each product undergoes strict quality control and testing to ensure the stability and reliability of its performance. Application Scenarios

Packaging and Transportation

About Us

Qingdao KRD Machinery Manufacturing Co., Ltd., situated at No.108 Shuangyuan Road, Chengyang District, Qingdao, is a high-tech entity specializing in the precision machining of diverse mechanical components. Our products find extensive use in photovoltaic cutting equipment, machine tools, engineering machinery, and agricultural machinery. Industry customers trust and support us, recognizing our dedication to quality.

Our company boasts over 50 state-of-the-art gantry machining centers, horizontal and vertical machining centers, and CNC lathes. With over a decade of robust technical expertise and rich industry experience, our production process encompasses machining, precision casting, forging, welding, milling, and wire cutting. We possess the capability to analyze, design, program, clamp, and process, independently managing the entire quality inspection and other integrated enterprise services.

The company operates with a scientific and rigorous management system, backed by stringent product quality testing equipment. Quality control extends to all facets, ensuring comprehensive oversight. We remain steadfast in our business principles of 'quality first, customer first,' dedicated to providing superior products and services to meet your needs.

For more detailed information about our products, please feel free to contact us at any time. We eagerly anticipate the opportunity to collaborate with you and provide solutions that meet your specific requirements.

FAQ

Q: Are you a factory or trading company?

A: Yes, we are a factory. With more than 10 years experience in precision machining, located in Chengyang District, Qingdao.

Q: What do I need for offering a quote?

A:We need you to provide us with detailed drawings including information on material, size, quantity and finish.

Q: How about the MOQ?

A: MOQ depends on your need , besides, we welcome trial order before mass-production.

Q:What will you do for after sales?

A:We will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help.

Q: How do I know about the production?

A:We will double confirm your requirements and send you the sample before the mass production as you required.

Q: Will my drawings be divulged if you benefit?

A: No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q: Is it possible to know how is my product going on without visiting the company?

A: We will offer a detailed products schedule and send weekly reports with pictures and videos

Q: What will you do if we receive defective parts?

A: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

>>

Hotel Used Coffee Pot Water Jug Can Be Put in The Dishwasher Double Wall Stainless Steel 304 Tea Pot Vacuum Flask

>>

Chinese Hot Sale 3 5 Gallon PC Barrel Blowing Moulding Machine with Servo Motor

>>

For Wholesale Auto Brake System Clutch Pressure Plate 41300-23138 4130023138 41300 23138 Fit For Hyundai For KIA Korean Car

>>

Roll Label to Sheet Cutting Machine

>>

Hot sale!!! portable goat milking machine for sale/ vacuum milking machine

>>

Solar USB Charger Bag Foldable Mobile Phone Battery Pack Power Bank Factory Original

>>

2014 2019 GLA250 GLA W156 Rear Bumper Lower Diffuser Trim 1568852600

>>

Super Quality Automatic Fish Feeding Machine Fish Feed Maker Machine Medium Fish Feed Machine Complete Fish Feed Machines

>>

ASTM A234 WPB Fitting

>>

Best Selling EU Standard Fly Metal Laser Printer Auto Parts Laser Marking Engraving Machine for Metal

>>

13 Gauge HPPE Knitted 5 Level PU Coated Anti Cut Glove

>>

Animal Poultry Husbandry Equipment Heat Gas Brooder Heater for Chicken Farming House

>>

SK40P CNC Horizontal Lathe Machine

>>

Aluminum alloy MTB bike Presta Valve Core Remover Tool

>>

Camera Interface for AUDI A4L 10.1" 2020

>>

Pet Bottle Recycling Machine with Crusher Washer Dryer

>>

Opening Milling Machine for Three Inch

>>

Sintering Pallets car sinter machine carts

>>

Automatic Good Price 5 Liter 10 LTR Jerrycan Blowing Moulding Machine HDPE Plastic Blow Molding Machine

>>

Kent KHB30, KHB3GII, KHB50, KHB5GII, KHB80, KHB8GII, KHB100, KHB10GII, KHB10GII-HD hydraulic breaker chisel tool