Basic Info.

Standard

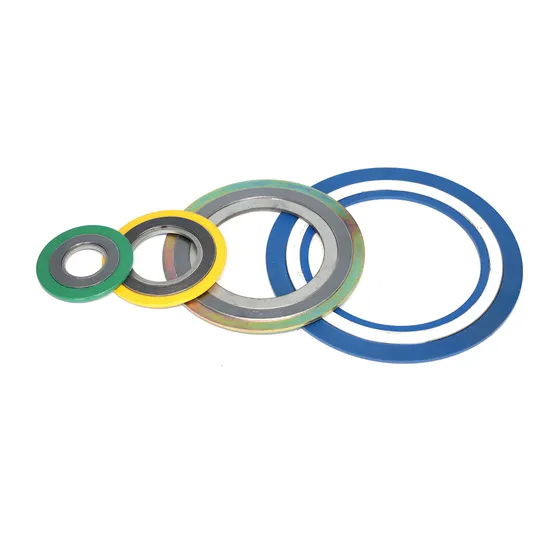

Standard, Nonstandard, Special-Shaped Type Spiral Wound Gasket

Transport Package

Wooden Case

Production Capacity

4000000 Piece Per Year

Product Description

WHAT IS A SPIRAL WOUND GASKET?Introduction to Spiral Wound Gasket (SWG):A Spiral Wound Gasket (SWG) is a type of industrial gasket that is widely used in high-temperature, high-pressure, and corrosive environments. It consists of a V-shaped metal strip and a softer filler material that is wound in a spiral fashion to create a resilient sealing surface. This article will discuss the construction, types, advantages, applications, factors to consider, installation, maintenance, challenges, and importance of Spiral Wound Gaskets.

What are the materials used in Spiral Wound Gaskets (SWG)?Construction of Spiral Wound Gaskets:The construction of a Spiral Wound Gasket comprises four main parts: the outer ring, inner ring, winding strip, and filler material. The outer ring is made of carbon steel or stainless steel, and it acts as a compression stop to prevent over-compression and gasket blowout. The inner ring is made of the same material as the winding strip, and it provides additional support to the gasket. The winding strip is typically made of stainless steel or other alloys and is wound in a spiral fashion to create the gasket's sealing surface. The filler material is placed between the winding strip to enhance the gasket's sealing properties.

Compared to metal wound gaskets, ShilongSeals metal wound gaskets achieve a good seal under lower stress (bolt load). Durable LongTM metal wound gaskets can be produced according to various international and industry standards, such as ASME B16.20,DIN,BS,JIS,GB,HG standards and so on. The quality assurance system conforms to ISO9001 standard.PRODUCT SPECIFICATIONS

| Types of Filler Materials Used in Spiral Wound Gaskets (SWG): |

| Filler Material | PRODUCT SPECIFICATIONS | Abbreviation |

| Graphite | Graphite is a popular filler material due to its excellent thermal and chemical resistance. | F.G. |

| PTFE(Polytetrafluoroethylene) | PTFE is another popular filler material known for its chemical resistance and low coefficient of friction. | PTFE |

| Mica | Mica filler material is known for its excellent heat resistance and is often used in high-temperature applications. | Mica |

| Non-Asbestos | Non-asbestos filler materials are used in applications that require good chemical resistance without using asbestos. | NAS |

| Ceramic | Ceramic filler material is ideal for applications that require high-temperature resistance and good electrical insulation. | CR |

Construction of Spiral Wound Gaskets:The construction of a Spiral Wound Gasket comprises four main parts: the centering ring, inner ring and winding strip that includes stainless steel belt and filler material.

The centering ring is made of carbon steel or stainless steel, and it acts as a compression stop to prevent over-compression and gasket blowout.

The inner ring is made of the same material as the winding strip, and it provides additional support to the gasket.

The winding strip is typically made of stainless steel or other alloys and is wound in a spiral fashion to create the gasket's sealing surface. The filler material is placed between the winding strip to enhance the gasket's sealing properties.

In order to match the working conditions of different pressure levels of metal wound gaskets, specific pressure and tensile force need to be applied to the winding of metal belts and non-metal fillers in the manufacturing process.

By matching different pressures, tensile forces and the thickness of non-metallic packing, the load or compression force required to compress the gasket will be very different. Generally speaking, the higher the density of the wound part, the higher the pressure class, the higher the load required to compress the gasket.

In low pressure classes,flange connections can provide lower compression loads. The low stress winding gasket needs to have a suitable gasket coefficient to achieve a good sealing effect. For

low-pressure tight stress conditions, we can customize the gasket winding density according to the specific requirements of the user's working conditions to ensure the sound sealing effect.

Warehouse:

Sample

>>

Custom Engineered Woodfloor Shell Inlays Floor Wood

>>

7*7*7cm Kids Folding Magical Puzzle Cube

>>

Cost Effective 2022 Eco Small Wholesale Reusable Lunch Bags Gel Instant Ice Pack Food

>>

Long Emergency Time 6h Bulb with Hook 40W LED Camping Light

>>

High Frequency Tube Mill Production Equipment for Automatic Pipe Welding Pipe Make Machine Machine for Plumbing Pipe Steel Pipe Making Machine

>>

5g Indoor MIMO Directional Panel Antenna

>>

SINOBI Masculine Sports Wristwatchs Innovative Dial Design Quartz Watchs Men Wristwatches Men S9837G-D

>>

Laboao Portable Ethanol Extraction Centrifuge System

>>

wholesales Japan Pocket WiFi 603HW

>>

Enamel Metal Badge of Gintoki Sakata From Gintama

>>

ASTM A325 Type 1 Heavy Hex Structural Bolts

>>

Bird Animal Patterns Small Handmade DIY Embroidery Kit Creative for Beginners

>>

Hot Sale New Retractable 3 In 1 USB Magnetic Charging Cable For Mobile Phone Cable Ios/Type-C/Android

>>

Reusable Chinese Crafts gift Bamboo Chopsticks

>>

Midleford Brand New Design Romantic Rose Red Piano

>>

Bathroom Ceramic Muslim Basin Wash Foot Arabia Sink Double Level Wash Basin Stand Pedestal Wudu Basin

>>

Portable Sewage Pump diesel water pump trailer for farm

>>

Dress Stiching Designs Istanbul Stylish

>>

Bronze Knight Sculptures Copper Cast Gift

>>

Wholesale Fish Tank Decoration Aquatic Accessories Underwater Plastic Artificial Aquarium Plant