|

US$3,000.00-8,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Processing Type

Mechanical Process

Match Machine

Weaving Equipment

Processing Level

The General Processing

Processing Trade

Processing with Material Supplied

Certification

ISO9001: 2000

After-sales Service

on-Site Installation

Spindle Distance

250,270,300,350

Transport Package

Standard Export Packaging

Production Capacity

500PCS/Month

Product Description

Big V-shaped recirculated bobbin creel is assorted with direct warping machine for chopped fiber. Its advantages include shorter creel body, no thread carrier between frame and creel, especially adapt

Keywords:Super-High-Speed Direct Warping Machine,Smart-high-Speed Sectional Warping Machine

Product Description

Big V-shaped recirculated bobbin creel is assorted with direct warping machine for chopped fiber. Its advantages include shorter creel body, no thread carrier between frame and creel, especially adapted for some chopped fibers which are sensitive to friction, working under low tension and high speed, be favorable to reduce tension difference of yarn and end breakage when warping. The interleaving creel optimizes the space utilization. The inner side of v-shaped creel could store bobbin, which is convenient for operation. The bobbin changing time is short so that can save idle period for warping machine. This kind of bobbin creel is especially fit for high speed warping.

Cut-off device

The yarn cutter can cut off yarns upon the change of yarn batch. The yarn cutter is provided with the electrical blade and cuts off all yarns with movement of creel in one cycle. (patented technology)

Technical Features

1. Way of bobbin changing: put the bobbin in the inside of the creel in advance, change the bobbins collectively through driving and turning of endless chain.

2. Both sides of the creel is in V shape, adopting turning outside yarn guide type to guide yarn, no yarn carring plate, so the yarn founctioning freely and no yarn friction.

3. Breakage and monitoring:single spindle photoelectricity inspection,even the fine count yarn is also inspected accurately.

4. The broken-end electrical display per spindle row can show the row and the layer where ends are broken. It facilitates the handling of broken end and improves the production efficiency.

5. The yarn number preview function is provided. Press the Preview and implement the beaming. Then the total yarns distributed from bobbins will be shown for beaming. Compare it with the process setting and start the beaming only when two values are identical.

6. The tension difference in the back creel and front creel can be reduced by adjusting the angle through the tension roller. The minimum yarn difference can be gained through this nay. Another function of the tension roller is to unfasten the ties when start the machine again, which stopped when unreeling at high speed. It is good to high speed unreeling.

7. In order to avoide the yarn looseness when reducing the speed,every spindle has yarn clamp device, which can add soft brake to the yarn when starting and stopping.

8. Yarn cutting: manual, or power driven

9. Deduster: intermittent air blast.

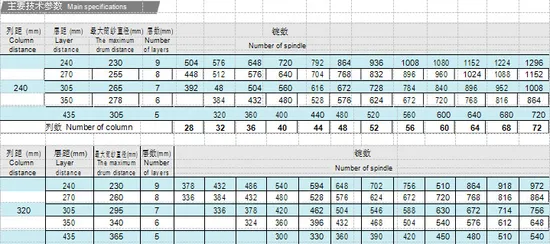

10. Independent control casing is installed in front of creel. Product Parameters

Detailed Photos

Packaging & Shipping

PACKAGING PICS:

Company Profile

WHO ARE WE?

Liaocheng Wetex Import & Export Co., Ltd, with over 20 years of experience, specializes in fully automatic warping and high-speed weaving machinery. We have our own factory, a research and development center, and partnerships with leading domestic manufacturers. Our high-quality products are recognized in over 20 countries across Asia, Europe, the Americas, Oceania, and Africa. Known for competitive pricing and precision, Wetex provides comprehensive solutions, including on-site installation and support in various languages. We are dedicated to innovation and customer satisfaction, making us a trusted name in the textile machinery industry.

Our Advantages

WHY US?

01 Industry experience

With rich experience in the industry, Wetex gives professional guidance and advice according to the needs of customers.

02 Customer Oriented

Wetex always puts customer's satisfaction as the first place, from professional sale suggestion, order tracking, to after sale one-site service, offering customer a life-cycle support.

03 Long-term cooperation

Wetex offer long warranty period, flexible payment methods, online and offline exclusive services, etc. are all to ensure long-term and stable cooperation

04 Own factory endorsement

OUR TEAM:

EXHIBITIONS WE ATTEND:

SERVICES WE OFFER:

FAQ

1.Q:What are your payment terms?

A:L/C,D/A,D/P,T/T,Western Union,MoneyGram

2.Q:What is your logistics method?

A:Express,sea,lan,air

3.Q:How long is your lead time?

A:30-90 Days

4.Q:How about your after-sales service?

A:We offer engineers available to service overseas under merchandiser's supervision and translation

5.Q:Can i go to the factory for a field trip?

A:Welcome to our old and new friends to visit our factory very much,In addition,if you wish we will send you our instructions and relevant information to facilitate a face-to-face meeting 6.Q:Are you a manufacturer or trading company?

A:We are the leading manufacturer of high speed rapier loom and fully automatic sectional warping machine. And also with many years business relationship with Local textile machinery accessories factories, we also have a trading company to supply one stop solution for our foreigh customers

Wetex is not only a trading company but owned self factory to gurantee the quality, delivery time and price effeciency

>>

Wellon CNC Vertical Machining Center/CNC Milling Machine Vmc850 Vmc855 Vmc1160

>>

Customize Plastic Bushing Forging Machine Parts Shaft Sleeve

>>

Garlic and onion PP woven weed control mat,plastic ground cover black weed kill fabric,100gsm anti grass gardening mat

>>

Custom decorative perforated metal sheet facade cladding

>>

Taijia ferromagnetic objects finder Concrete scanner Rebar Steel Locator

>>

Wholesale LED Moving Wedding Party Flameless Romantic Electronic Flicker Candle Set with Remote Control

>>

Grain Bean Seed Drum Type Precleaner Machine

>>

Cleaning Brush with Plastic Handle and Replaceable Microfiber Head

>>

5L bottle linear type water filling machine pure bottled water filling machine

>>

Multi-Functional Gas Cooker Stove with Integrated Oven for Chefs

>>

Bathroom Rain Shower Head Waterfall Skincare Shower Head Chrome

>>

Rectangular Connector Plug Socket JL29-06TKY-S300 JL29-06ZJB/ZJW TKH

>>

Mechanical automatic diameter feeding, automatic net out and net falling, reinforced mesh welding machine

>>

TGLG-PP-150-400-1.5High strength honeycomb geogrid chamber slope protection retaining wall

>>

Electricity clamping radial drilling machine Z3040X14/II Automatic feed radial drilling machine

>>

2.5t Ratchet Winch, 2m Strap, Vehicle & Equipment Lifter (40014001)

>>

Cheap 2 Axis CNC Mini Lathe Machine (BL-Z5/Z6)

>>

Tensile Sample Cutting With the XK200 CNC Mill

>>

Maxi Roll Tissue Paper Production Line Industrial Roll Maxi Roll Making Machine

>>

Plasma Cutting Consumables Electrode Nozzle Shield Cap Swing Ring for Hypertherm/Kjellberg/Thermal Dynamics/Esab/P80/Ygx/Yk100