|

US$88.00-157.00

|

50 Pieces

(MOQ)

|

Basic Info.

Model NO.

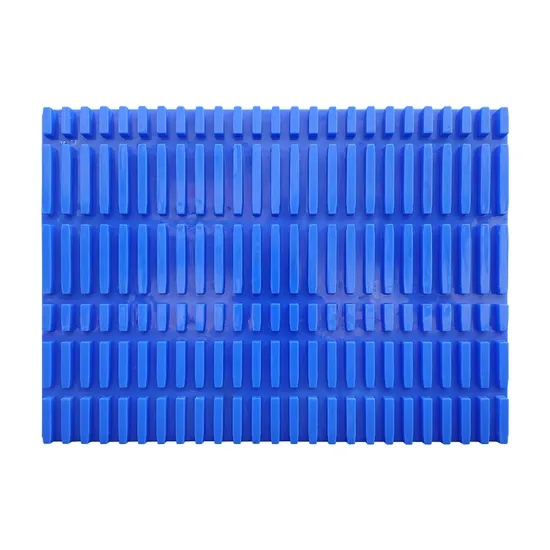

XF12590-175 Ribbed Nine-Leg

Transport Package

Wrapped by Plastic Film

Specification

1250mm*900mm*175mm

Trademark

Customized Logo

Production Capacity

200000PCS/Year

Product Description

PRODUCT PARAMETERS

The dedicated printing pallet product series are specially customized and developed plastic pallets tailored to the characteristics of the printing industry. Xingfeng printing pallets are made of high-quality, eco-friendly modified materials, featuring recyclability, aesthetic appeal, resistance to insect infestation and mold, no burrs, and exceptional durability. Currently, this series boasts over 30 models, primarily designed to fit with renowned printing equipment brands such as BOBST, HEIDELBERG, KBA, KOMORI, MANROLAND, and MITSUBISHI/RYOBI. They are suitable for various aspects of the printing industry, including paper transportation, placement, circulation, and continuous feeding during the printing process.

Application of Printing Pallets in Printing Processes 1. Paper Cutting Process The raw paper is picked up and placed on a cutting machine, cut to the set dimensions, and then placed on a plastic pallet. For printing equipment with uninterrupted paper replacement functionality, ribbed plastic pallets are generally used to hold the paper. For other printing equipment, flat pallets can be used.

2. Warehousing

The cut printing materials are loaded onto plastic pallets and directly warehoused with the pallets, ready for subsequent printing use.

3. Printing (Uninterrupted Paper Feed)

The cut paper is fed into the paper feed platform of the printing machine to start printing. When one pallet of paper is nearly exhausted, an insertion pole (steel tube provided with the machine) is inserted into the bottom of the paper through the groove of the pallet and placed on the pole holder. At this point, the pole lifts the paper, and the plastic pallet is lowered and removed using a lifting platform. Then, the second pallet of paper is forked onto the lifting platform, which rises to the pole position. The pole is then withdrawn, allowing the remaining paper from the first pallet to rest on the second pallet. This process is repeated to achieve uninterrupted paper feed.

4. Post-Printing (Paper Reception)

The printed pallets are placed at the paper output of the printing machine to receive and hold the printed products. They are then warehoused with the pallets or transferred to the next process. (Note: For products requiring second printing, ribbed pallets are generally used for paper reception to repeat the previous printing process. Otherwise, flat pallets are more commonly used.)

>>

Medical science anatomy 9parts puzzle plastic anatomical 3d human brain model

>>

Factory Auto Paint Booths Spray Paint Cabinet

>>

Repair Tools Chrome Vanadium Steel Screwdriver Set

>>

GE 369-H1-R-M-0-0-0-E Motor protector

>>

Double Deep Pallet Asrs Automated Warehouse Storage System

>>

Genuine cow/buffalo leather belt for men automatic buckle ratchet wholesale customized flexible hot sale OEM ODM

>>

Glue Spreader Roller Plywood/Hot Press Plywood Making Machine/Hydraulic Melamine Press Machine

>>

3207-2RS P5 bearings ,35*72*27mm,High performance double row angular contact bearing

>>

GGJ type low voltage reactive power compensation cabinet

>>

Top Sales 100% Original SD Card 16GB 32GB 64GB 128GB 256g Memory Cards with Adaptor for Sandiskk

>>

Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine

>>

Gr-168/2 Industrial Side Wall Indoor Slipper Sewing Machine

>>

Almond Slicer/Peanut Slicing Machine/Commercial Almond Flakes Machine

>>

Automatic Pillow Type Wrapping Machine Bread Biscuit Candy Bar Chocolate Wrapping Machine

>>

2UUL SC39 Solder Wire for Battery Metal Plate Welding Repair Without Spot Welding

>>

XCMG Folding Arm Working Platform Xga16AC China 16m Used Towable Boom Lift Platform for Sale

>>

Automatic Organic Compost Making Machine for Farm 5 Kg Compost Making Machine Per Second

>>

Auto Spare Parts car grill Car Bumper Front Grille Moulding for Camry 52711-06160 For Toyota

>>

Chalk Board Whiteboard Steel Sheet Raw Material

>>

Nano-Grind Aquatic Feed Processor