Basic Info.

Type

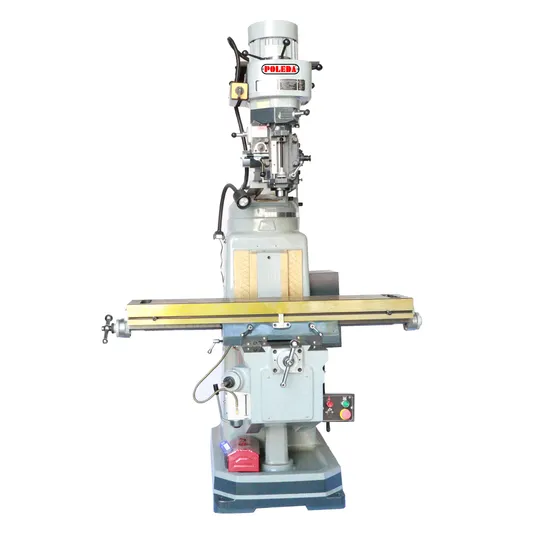

Worktable Milling Machine

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Overall Welding Tooth

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Certification

CE, ISO 9001

Transport Package

Wooden Pallet or Wooden Box

Specification

2000*1600*2300

Product Description

Product Description

The milling machine stands as a crucial machine tool, adept at cutting materials on machined parts using a rotating tool. Renowned for its versatility, this machine excels in metal cutting processes, enabling the machining of planes, surfaces, and gear parts. Additionally, it offers capabilities for drilling, reaming, boring, and more.

Basic Structure of the Milling Machine:

The fundamental structure of the milling machine comprises several key components, including the bed, sliding table, workbench, horizontal shaft, column, beam, guide rail, and motor.

1. Bed: The bed serves as the foundational support of the milling machine, accommodating various components. Typically cast for enhanced stability and robust rigidity, the bed ensures reliable operation.

2. Slide Table: The slide table is a dynamic component, facilitating forward and backward movements on the bed. It is integrated with a workbench and a horizontal shaft, enabling precise positioning and processing of the machined parts by maneuvering the slide table.

3. Workbench: The workbench acts as the operational platform of the milling machine, designed to securely hold and fix machined parts. It offers rotational, tilting, and other movements to accomplish intricate and complex machining tasks.Machined partprocessing.

Product Parameters

Structural characteristics

1. The base, fuselage, workbench, middle slide seat, lifting slide seat, and other main components are cast using high-strength materials, ensuring robust construction and durability.

Additionally, these components undergo artificial aging treatment to guarantee the long-term stability and reliability of the machine tool.

2. The milling head is equipped with a turret milling head, and the main shaft offers both manual and micro feeding methods, enabling precise and convenient processing.

The milling head can be adjusted ±45° in the vertical plane and 360° in the horizontal plane, significantly expanding the machining range of the machine.

3. The vertical and horizontal table supports three feeding methods: manual feed, mobile feed, and mobile fast feed. The mobile feed can achieve 8 different feed speeds.

This versatility meets various processing requirements, while the fast feed function allows the workpiece to reach the machining position swiftly, reducing non-machining time.

4. The lifting platform Z-lift can be operated manually or through maneuvering, with both methods interlocked to eliminate unsafe factors.

5. The table's X-direction travel extends up to 800mm. The guide pairs in the X, Y, and Z directions undergo ultra-audio quenching, precision grinding, and scraping treatment,

Enhancing accuracy and significantly prolonging the machine's service life.

6. The manual lubrication device ensures forced lubrication of the longitudinal, horizontal, and vertical lead screws and guide rails, minimizing wear and maintaining the machine's efficient operation.

Moreover, the cooling system allows for adjustable coolant flow via the nozzle, catering to diverse processing needs.

7. The machine tool's operating system is ergonomically suspended on the upper right side through the support arm, making it easy to operate.

The operation panel features intuitive and figurative symbols, simplifying the user interface.

8. The turret milling machine spindle can be configured with R8, NT30, or NT40 options,

9. It is equipped with an improved electrical box and controller, featuring 110V and 220V output sockets.

| Product Name | Milling machine |

| Product model | 3M/3S/4M/4S |

| Product technical parameters | |

| dimension | Table size | 1270*254MM |

journey | Left and right stroke(X) | 740MM |

| | Front and rear stroke(Y) | 380MM |

| | Up and down stroke(Z) | 360MM |

| | Arm reach | 520MM |

| | Distance from spindle end face to table surface | 50-410MM |

| | Table bearing | 300KG |

Principal axis coefficient | Spindle taper | R8 |

| | Spindle speed | 80-5440RPM(16-speed) |

| | Spindle travel | 127MM |

| | Spindle horse power | 3HP |

| Milling head | Milling head tilt Angle | 45° front and back |

| Lead screw | Three-axis screw diameter | Tr32mm |

| | Three-axis lead screw pitch | 5mm |

Machine profile dimensions | T-slot (Number * Size * Spacing) | 3-15.88*65MM |

| | Machine size (L * W * H)(MM) | 1750*1700*2200MM |

| | Approximate machine weight | 1280kgs |

| disposition | Accessories name | quantity |

Standard parts for machine tools | 1,Hand oil pump | 1 |

| | 2,Work light | 1 |

| | 3,Organ board + protective glue | 1 |

| | 4,Lever | 1 |

| | 5,Tools and toolboxes | 1 |

| | 6,Operating instruction | 1 |

Special parts for machine tools | 7,Two axis electronic ruler | 1 |

| | 8, X-axis automatic feed | 1 |

| | 9, 6 "flat pliers | 1 |

| | Clamp plate | 1 |

| | 11, chuck | 1 |

Detailed Photos

Our Advantages

Packaging & Shipping

Certifications

FAQ

1.What is the Minimum Order Quantity (MOQ) for your production?

A. The MOQ largely depends on your specifications such as color, logo, and more. For some standard items that we have in stock, the MOQ is just 1 set.

2.How do you ensure the quality of your products?

A. We have consistently prioritized maintaining high-quality standards. Our principle is to consistently provideour customers with superior quality, competitive prices, and excellent service.

3.What are the main products of your company?

A: We specialize in a variety of machines, including CNC Machines, Lathe Machines, Milling Machines, Grinding Machines, Vertical Machining Centers, DrillingMachines, Radial Drilling Machines, Sawing Machines, and more.

4. What are your trade terms?

A: We accept Ex-works, FOB, CFR, and CIF terms.

5.What are the Payment Terms?

A: We accept T/T with 30% initial payment upon order and 70% balance payment before shipment.

6.What CNC systems do you use?

A: We utilize CNC systems from FANUC, SIEMENS, MITSUBISHI, SYNTEC, and HCN, according to your preference.

7.How can I choose the most suitable machines?

A: Please send us your product drawings and application details, and we will recommend the most suitable machines for you.

8.What kind of packaging do you offer?

A: We typically use plywood cases to ensure all goods are in excellent condition. Customized packaging is also available.

9.Can your plant do OEM?

A: Yes, we can perform both OEM and ODM services for our customers.

10.What is the warranty period?

A: The warranty period is one year after delivery. Beyond this period, we offer lifetime service for our machines.

>>

Silo Feeding Systems Bulker Unloading Pneumatic System

>>

Multifunctional Vegetable Fruit Basket Wire Lightweight Metal Organizer Rack Storage Basket for Kitchen Counter

>>

Taijia TEM-620XH reinforcement testing rebar detector scanner price rebar scanner and cover meter

>>

Newest products replacement car hood-steel for model T33 Rogue 2021

>>

Factory wholesale waterproof pe ce oversleeve

>>

755nm picosecond laser tattoo removal 808 nm diode laser hair removal machine

>>

Mopa Color Laser Marking Machine for Stainless Steel Cooper Brass Chromium Nickel Molybdenum Alloy

>>

Factory Hot Artificial Stone Slab Calacatta Quartz White Quartz Floor and Kitchen Bench Top Grey Cut to Size Flooring Floor Tile

>>

3000L 1000L IBC Blow Molding Machine for Making Plastic Water Tank

>>

Byloo Wholesale Factory Price Fitness Equipment Spring Grip Chest Expander Power Twister Bar

>>

2t/H Automatic Animal Feed Pellet Production Line/Pellet Mill Plant for Animal Feed Pellet Making

>>

AC220V 50Hz Waterproof Grade IP66 Explosion Proof High Bay Light

>>

Hot Sale Paper Loader Aligning Stacker Machine Fully Automated Paper Loading Machine

>>

Side 3.5kw Spindle Hole Drilling Machine for Door Side Working Machine

>>

5-Axis CNC Machining Gas Shielded Brass Connecting Pipe Fittings

>>

Stainless Steel Cooling Jacket Wine Storage Pot with Side Manhole

>>

Car Body Parts Tail Lamp 2003 81551-33270 For Camry

>>

Lowest Price Automatic Fly Ash Concrete Cement Hollow Block Brick Making Machine

>>

Walking Tractor Corn Reaper One Row Corn Silage Harvester Corn Harvesting Machine

>>

Flight Approved Carry-on Luggage Hand Waterproof Light Business Backpack Durable Large Weekend Waterproof Travel Bags