|

US$29,999.00

|

1 Piece

(MOQ)

|

Basic Info.

Separation Mode

Filter Type

Operating Type

Continuous Type

Centrifuge Type

Gkh Centrifuge

Drum Maximum Speed

1550r/Min

Transport Package

Wooden Cases

Specification

2215*2300*2200mm

Production Capacity

50sets Per Year

Product Description

Product Description

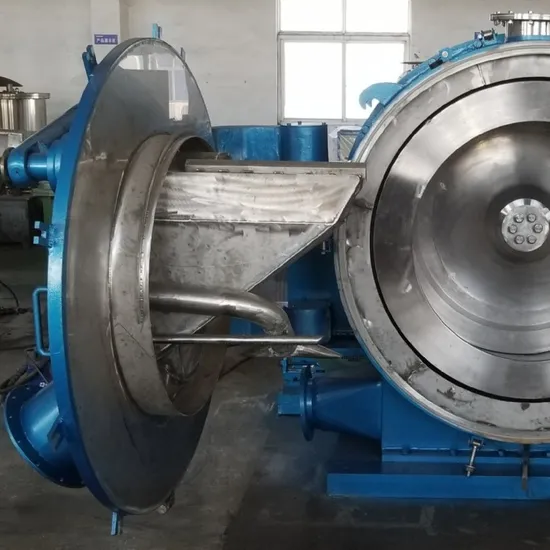

Scraper centrifuge is a type of full-automatic centrifuge with continuouslywarking and batch operation. Accordingto the structure. it can be divided intoSiphonic Scraper Centrifuge (GKH series)and common scraper centrifuge (GK series).The scraper centrifuge can be switchedbetween automatic and manual operation, so it can realize the periodiccyclic operation of feeding dehydration,washing and discharging of the feed material.Compared with common scraper centrifuge, the siphonic scraper centrifugehas siphonic force like vacuum, so it hasbetter production capacity and separationeffect. Especially, it is suitable for the feed material which has small solids, highviscosity. slow filtration and that needs towash the filter cake.

Product Parameters

Item / Model

| GKH-450

| GKH-800

| GKH-1000

| GKH-1050

| GKH-1250

| GKH-1600

|

Drum diameter (mm)

| 450

| 800

| 1000

| 1050

| 1250

| 1600

|

Drum height (mm)

| 300

| 450

| 500

| 500

| 630

| 1000

|

Drum volume (L)

| 21

| 110

| 200

| 210

| 335

| 879

|

Loading capacity (Kg)

| 26

| 140

| 250

| 260

| 500

| 1100

|

Max. Speed (r/min)

| 2600

| 1500

| 1400

| 1400

| 1200

| 950

|

Max. Separating factor

| 1700

| 1007

| 1095

| 1150

| 1006

| 808

|

Motor power (KW)

| 15

| 37

| 45

| 45

| 75/90

| 132

|

Size including shock absorber (mm)

| 1800×1375

×1902

| 2439×1900

×2150

| 3050×2400

×2192

| 3050×2400

×2192

| 3875×2500

×2612

| 5620×3200

×3930

|

Weight (Kg)

| 2500

| 5800

| 6200

| 7800

| 8000

| 20000

|

Weight including platform (Kg)

| 2500

| 10800

| 13200

| 15000

| 16000

| 39000

|

Main application

Model GKH centrifuge is the filter equipment characterized with continuous running, scraper discharging and intermittenent operation, applicable to the separation of the suspension liquid containing medium-sized granules or fine granules(0.01mm-5mm). It can also be used for the separating of the suspension liquid containing short fibers(with the fiber length less than 4mm), with the concentration of the suspension liquid being 10%-60%. With hydraulic and electric joint control mode adopted, this series of centrifuges are capable of high degree of automization, with such working processes as by means of PLC for full automatic control. The horizontal scraper discharging centrifuge has good adaptability to the material to be processed and thus can be widely used in such industrial fields as chemical, light industry, food, etc.

Working principle

The main motor is driven by VFD. When the basket speed reaches the rated speed, the feed valve is turned on and the material feed starts. Under the action of the centrifugal force, The solid phase is distributed on the inner surface of the filter cloth (filter net) evenly, while the liquid phase is filtered through the filter net and the basket wall hole mostly, and thrown out through the tangential drain pipe in the shell, and the thickness of cake layer in the basket increases with the prolonging of the feed time.

When reaching the predetermined time (or the thickness of the cake is predetermined), the feeding valve is closed automatically (The feed time can be determined according to the characteristics of the material. It can be measured in the first start-up and commissioning, or the material level controller is used to control the feed volume.) for the material needed to be washed, after stopping feeding for a certain time, the washing valve opens automatically, washing liquid will wash and spray the cake layer in the basket, the washing valve shut down automatically after a certain time washing. The basket is rotating in the continuous speed liquid phase are separated and thrown out.

Continuous separation for a period of time to meet the requirement of the solid separation, scraper move, The scraper scraped the filter cake into the filter cake layer along the rotary basket radial, and the filter cake was conveyed out of the body by scroll. After the discharge was finished, the scraper was rotated and reset. If you want to wash the net, open the washing valve, and wash the net by washing liquid to make the filter net regenerate (the washing number can be determined according to the characteristics of the material, and it can be carried out once after repeated cycles). after the end of washing net, it is a complete operation cycle, the inlet valve is opened again, the centrifuge comes into next cycle.

Every action of the machine is completed under the control of the electric-hydraulic system(automatic / manual). The hydraulic station consisting of the oil blotter and filter, the oil pump, the electromagnetic valve, the motor, the one-way valve, the overflow valve, the pressure gauge, the oil tank, etc.

Features

1. Horizontal structure: floating platform shock absorption system, the machine runs smoothly and the vibration noise is small.2. Flushing device: The residual filter cake and filter medium can be reversely soaked and flushed to achieve filter cloth regeneration.3. Skimming device: suitable for separating materials containing proteins, colloidal substances, etc.4. Siphon device: hydraulic operation, fully automatic control, smooth operation. Three-position control can complete separation, deliquidation, washing and other tasks with accurate angle and good repeatability.5. Door cover large corner design: It adopts a fully automatic hydraulic locking system, which is safe to operate, more convenient for inspection, maintenance and cleaning, and has low labor intensity.

>>

1inch 2inch 3inch Water Pump Kit, High Pressure Pump End

>>

Custom Printed Large Insulated Motorcycle Backpack Grocery Tote Food Delivery Insulated Cooler Bag

>>

Jumping Cue Tip

>>

agriculture pet melt blown 3mm thickness pp spunbond spunbond needle punching thick pla nonwoven felt water

>>

Factory Hydraulic Piston Main Pump Shaft Repair Kits Swing Motor Metal Pump Spare Parts

>>

Module spare partsABB DSAI130D 3BSE003127R1

>>

China Rubber Banbury Mixer Machine for High-Quality Dispersion Mixing Kneader

>>

Automatic Pet Plastic Bottle Extrusion Blow Molding Machine Price

>>

Automatic PLC Controlled Vffs Wrapping Machine

>>

CE/Tped Shanghai, China (Mainland) Sefic Steel Cylinder 50kg Helium Gas Cylinders

>>

Beauty foundation puff makeup sponge non latex Dry And Wet Makeup Brush Puff

>>

Agricultural Handheld Garden Farm Mini Cultivator Tiller Weeding Machine

>>

12V Electric Car DC Air Conditioner Scroll Compressor for Hybrid Cars

>>

0.45X1250mm Ral7024 G550/CGCC/TDC51D+Z Galvanized Prepainted Steel Color Coated PPGL/PPGI with Customized Color

>>

Electrical insulation silicone rubber tape

>>

new house project kitchen wood colored aluminum safety glass grill design sliding window with architrave

>>

Chinese Automatic High Precision Ck6130 CNC Bench Mini Metal Turning Lathe Machine

>>

custom cnc machining mill turning fabrication sheet metal stamping services

>>

New Crop Harvest Walnut/Walnut in Shell / Walnut Kernel

>>

Milk Uht Sterilization Machine Wine Sterilizer Used for Sweet Wine Bottle