|

US$23,200.00-23,500.00

|

1 Piece

(MOQ)

|

Basic Info.

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Double-Spindle Processing

Numerical Control

CNC/MNC

Processing Precision

0.02~0.03(mm)

Performance Classification

High-End CNC Machine Tools

Characteristic

High Rigidity and Precision

Other Optional Function

Depending on Customers Needs

Processing Time

Techincian Will Do The Assessment

Max Process Diameter

26mm

Specification

1950X14550X1700mm

Production Capacity

30sets/Month

Packaging & Delivery

Package Size

2200.00cm * 1700.00cm * 2130.00cm

Package Gross Weight

2000.000kg

Product Description

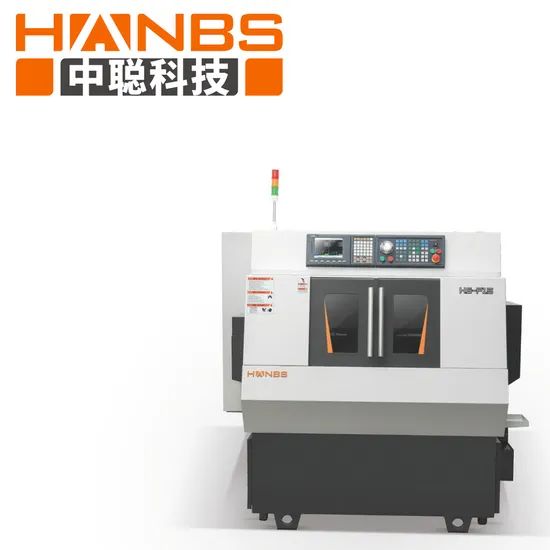

P15 - accuracy cnc lathe with higher rigidity

Product Description

High precision and repetitive precision:

CNC machine tools can perform extremely precise machining, and their machining errors can be controlled within a very small range. In addition, they can repeat the same operation time and time again, ensuring the consistency of each produced component.

Prossing ability of complex shapes:ce

Traditional machine tools have their limitations in processing complex components, while CNC machine tools can easily process various complex shapes and details. They can perform multi axis linkage to process complex geometric shapes such as curves and slopes.

High efficiency and automation:

CNC machine tools can operate continuously without manual supervision, reducing human errors and the need for manpower, effectively improving productivity. The functions of automatic tool changing and workpiece clamping greatly shorten non processing time.

Flexibility and programmability:

CNC machine tools are controlled by computers and can easily adapt to different production requirements with just programming changes, especially suitable for customization and small batch production.

Improving working conditions:

The application of CNC machine tools reduces the need for manual operation, greatly improves the working environment of operators, and reduces labor intensity.

Product Photoes

Product Uses

The following are four specific application scenarios of CNC Lathe:

New energy vehicles

medical treatment

Communication accessories

Household appliances

Electronic cigarette

Precision component processing

hydraulic pressure

Pneumatic

Product Information

| Processing parameters | Maximum processing diameter | φ26mm |

| Maximum machining length 2.5D | 50mm |

| Maximum axial drilling diameter | M10mm |

| Maximum axial tapping size | M8 |

| Max. spindle speed (short time) | 10000rpm |

| Max. back spindle speed (short time) | 12000rpm |

| Max. workpiece removal length | 40mm |

| Maximum stroke | X1 axis | 375mm |

| Z1 axis | 180mm |

| X2 axis | 375mm |

| Z2 axis | 180mm |

| Cutting tool | Size of cutter plate | 390mm |

| Maximum number of tools | 8 |

| Tool (turning tool) | φ16X16 |

| Sleeve | φ25 |

| Height from tool plate holder to spindle centre | 45mm |

| Collet | Spindle collet | HB26 |

| Back spindle chuck | HB26 |

| Feed rate | X1/X2 axis feed rate | 15m/min |

| Z1/Z2 axis feed speed | 15m/min |

| Motor | Spindle drive power | 2.5/3.7KW |

| Back-axis drive power | 1.5/2.5KW |

| X1 X2 Z1 Z2 power | 1.1KW |

| Cutting oil | 0.4KW |

| Other | Spindle centre height | 1010mm |

| Air pressure flow | 0.7mpa 0.5m3/min |

| Main breaker capacity | 40A |

| Input power | 5.4KW |

| Weight | 2700Kg |

| Dimension | 1950X1455X1700mm |

Processed Product Display

company profile

Centering machine, also known as spindle mobile lathe, refers to the processing of precision shaft parts, relying on the axial movement of the spindle clamping material for turning and milling processing, supplemented by synchronized guide device, in the process of moving the spindle, the tool and the guide sleeve to always maintain the closest distance, so the processing of long and thin shaft parts and the overall accuracy of the same. CNC centering machine in addition to turning and side face milling functions, precision and complex parts can be shaped at a time, not only to improve the accuracy of the parts and eliminating the need for secondary clamping and other processes, dual spindle CNC centering machine main and auxiliary axes can be separated from the simultaneous machining, part of the machining process can be divided into the parts of the dual spindle CNC centering machine processing, a machine is equivalent to the processing efficiency of the two machine tools, equipped with an automatic oil-film type feeder and the receipt of the transfer device , which can realize the precision manufacturing plant. Equipped with automatic oil film feeder and material transfer device , it can realize fully automatic unmanned production of precision manufacturing factory!

Factory

Certifications

Patents

Some partners

Visiting

Exhidition

Loading and shipping

FAQ

1. What is the delivery period?

R: In general, the delivery period is about 30-45 working days.

2. What are the after-sales services?

R: We have a professional technical team that can solve your problems online 24 hours.

3. Does the product accept customized service? What aspects can be customized? (Such as color, shape, size, etc.)

R: Yes, customized service is feasible, such as printing your company logo and so on.

4. Do you accept small orders (or what is the minimum order quantity, etc.)?

R: Yes, we can also provide 1 set of machine.

5. How many years of production experience does your company have?

R: More than 10 years, we have several professional and experienced technical instructors to provide you with after-sales guidance.

6. What are the characteristics of the material of this product?

R:Our Swiss Lathe machine has been CE certified, and the geometric accuracy of the machine tool is in accordance with the factory standards and the Chinese General Rules for Metal Cutting Machine Tools GB/T1742.1-1998 (International ISO230-1-96).

>>

All Size Outdoor Garden Flower Fabric Pot High-Quality Grow Bags with Handles

>>

T3 Series Industrial Dual Channel Ultrasonic Water Meter Powered By Battery Residential Sandwich Insertion Water Meter

>>

300ml 500ml 1L 2L Small Stretch Blow Blowing Molding Machine

>>

Kitchen Cookware Sets

>>

China Factory Disposable CE ISO FDA Two Parts Three Parts Medical Syringes

>>

Heavy-Duty Diesel Engine Polystyrene Compactor for Waste Management

>>

China Wholesale High Quality Iron Powder Price for Brake Pads Friction Powder

>>

Automatic Conveyor Belt Weight Sorter Food Packaging Machine Processing Metal Detector with Check Weigher

>>

Steel Outlet Box Octagon UL Listed 1-1/2" Depth

>>

Industrial SSD Crusher Hard Drive Shredder

>>

Black/Grey Phosphated Good Quality Bugle Head Drywall Screw

>>

Hot Selling Plastic Lunch Box Water Bottle Set Thermos Tiffin Lunch Box Custom Logo School Bento Box for Kids Wholesale

>>

Full Automatic Toilet Paper Making Machine Price

>>

New brand durable mens shaving metal litchi wood double edge hand resin handle shaving safety razor

>>

High-Precision Injection Molding Machine for Custom Toy Production

>>

Precision Corn Harvesting Equipment 25 HP Single Row Corn Harvester

>>

100t Per Day Maize Mill Fully Automatic Maize Flour Mill Machine

>>

2020 New Arrival China Pro Adult Cheap Black 36V4AH Lightweight Front Disc-Brake Wholesale Foldable Electric Balance Scooters

>>

Personalized Custom Neck Strap Lanyards for ID Badges

>>

Quality products OEM aluminum titanium investment casting and foundry