Product Details

Product Description

Product Description

Product Description

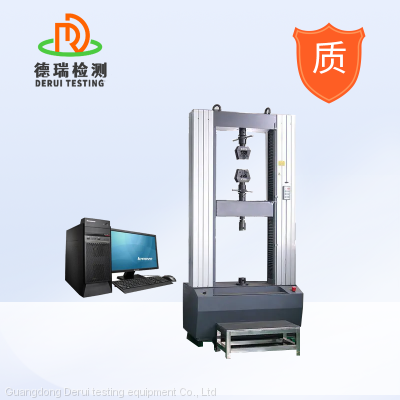

Computerized Double Column Tensile Testing Machine is used to test the mechanical properties of various materials such as static load, tensile, compression, bending,shearing, tearing, peeling and other mechanical properties of mechanical equipment. It is suitable for plastic plates, pipes, and other materials. Various physical and mechanical performance tests of profiles, plastic films and rubber, wires and cables, steel,fiberglass and other materials are developed for materials.

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection |

| Upper and lower limit switches |

| Load sensor with automatic retreat |

Applications

1. Tested sample: laminated materials, wood, leather, rubber & plastic, metal material, etc.

2. Different test with different grips: tensile, peel, tear, heat seal, adhesive, bend and open force.

3. Deformation under defined load: Test deformation under defined load of tested sample

4. Load under defined deformation: Test load under defined deformation of tested sample

Software can issue word/excel report with results for max. force, elongation, tensile strength, peel strength, tear strength,

compression strength, etc.

Tensile Strength Tester for Metallic Materials

In the field of quality control and performance research of metal materials, it is crucial to accurately grasp the tensile strength and other mechanical properties of materials. With excellent performance, advanced technology and humanized design, our metal material tensile strength testers become your right-hand man for mechanical property testing of metal materials.

I. High-precision testing performance

1. Accurate force measurement: The tester is equipped with a high sensitivity force transducer, the force measurement accuracy can reach ±0.5% FS (full scale). Whether testing high-strength alloy steel or softer non-ferrous metals, it can accurately capture force changes and provide you with reliable tensile strength data. For example, when testing common Q235 steel, key indicators such as yield strength and tensile strength are clearly and accurately displayed with minimal error.

2. Stable Displacement Measurement: Adopting high-precision displacement transducer, the resolution of displacement measurement can reach 0.001mm. During the tensile testing process, it can monitor the deformation of the sample in real time and accurately, which can help you draw an accurate stress-strain curve. This is of great significance for studying the deformation behavior of metal materials at different stress stages, as well as evaluating the processing performance of materials.

3. Wide range adaptability: The tester has a wide range of force values, from as low as a few Nm to as high as hundreds of kilonewtons, which can meet the testing needs of a variety of different specifications and strength levels of metal materials. Whether it is tiny metal parts or large metal structural parts, you can find the appropriate test range on this tester to ensure the accuracy and reliability of the test results.

Second, advanced technology configuration

1. High-performance drive system: the drive system is composed of AC servo motor and precision ball screw, which has smooth operation, low noise and high transmission efficiency. During the testing process, it can realize uniform loading, and the loading speed can be adjusted within the range of 0.001 - 500mm/min, which can meet the requirements of different testing standards on the loading rate. For example, in the implementation of GB/T 228.1-2010 “Tensile Testing of Metallic Materials Part 1: Room Temperature Test Methods”, the loading speed can be accurately operated according to the standard.

2. Intelligent control system: Equipped with advanced microcomputer control system, the test process can be fully automated. You only need to input the test parameters on the operation interface, such as sample specifications, test standards, loading speed, etc., and the system will automatically complete the test process and display the test data and curves in real time. In addition, the system is also equipped with data storage, query, printing and other functions, which is convenient for you to manage and analyze the test results.

3. Reliable Data Acquisition and Processing System: The data acquisition frequency is as high as hundreds of times per second, which can quickly and accurately collect force value, displacement and other data. At the same time, the built-in data processing software can automatically calculate the mechanical property indexes of metal materials, such as yield strength, tensile strength, elongation, etc., according to the collected data, and generate detailed test reports. The test report format can be customized according to the user's needs to meet the reporting requirements of different industries and customers.

Humanized design and convenient operation

1. Simple and intuitive operation interface: the operation interface adopts a large LCD screen, full Chinese menu prompts, easy to understand the operation. Even first-time users can familiarize themselves with and master the operation of the tester in a short time. On the interface, you can clearly see the setting options for each test parameter, real-time test data and dynamic stress - strain curve, so that you can always understand the progress of the test and the results.

2. Safe and reliable protection devices: To ensure the safety of the operator, the testing machine is equipped with multiple safety protection devices. For example, the protective door is made of transparent high-strength Plexiglas, which is not only convenient for you to observe the testing process, but also in the testing process, if the protective door is opened accidentally, the system will stop running immediately to avoid accidents. In addition, the machine is also equipped with overload protection, limit protection and other functions to effectively protect the tester and samples from damage.

3. Convenient Sample Installation and Replacement: The fixtures of the tester are well-designed and easy to install and replace different types of samples. Whether round, square or shaped metal samples, they can be firmly clamped by the corresponding fixtures to ensure that the samples will not slip or fall off during the test. At the same time, the fixtures can be changed quickly and easily, which greatly improves the testing efficiency.

Fourth, a wide range of application areas

1. Metal material production enterprises: In the production process of metal materials, the need for quality testing of raw materials and finished products. Our tensile strength tester can be used to test the tensile properties of various profiles such as metal plates, tubes, bars, etc. It helps enterprises to control the quality of their products and ensure that the metal materials shipped from the factory comply with the relevant standards and customer requirements.

2. Machinery manufacturing industry: when choosing metal materials, machinery manufacturing enterprises need to understand the mechanical properties of the materials to ensure that the mechanical equipment manufactured has sufficient strength and reliability. By using this tester for tensile testing of different metal materials, enterprises can provide accurate data support for product design, optimize material selection, and improve product quality and competitiveness.

>>

Oil Slip Resistant Lightweight Keep Work Boots

>>

house external window shutters motorized exterior aluminum shutters

>>

Building Materials Aluminum Perforated Metal Wind Dust Fence

>>

bioballs round 3cm bio ball media filter

>>

A Class W176 Manual Folding Mirror Assy Side Rearview Mirror Assembly 1768100176

>>

Ophthalmic Equipment Auto Refractor Digital Autorefractometer Optical Refractometer Medical Equipment

>>

Outdoor Custom Commercial Trampoline Manufacturer for Kids 12FT 10FT 8FT 16FT Trampolines with Enclosure Net Basketball Hoop Ladder

>>

aluminum frame bathroom door interior glass door with door casing

>>

Pink Shipping Boxes for Small Business Small for Mailing Shipping Storing Christmas Gifts WrappingCorrugated Cardboard Gift Box

>>

Single-Channel Inductive Loop Vehicle Detector (PD-132)

>>

Full Servo Three-Piece Baby Diaper Pull up Pants Machine

>>

Home Automatic Chicken Pelletizer Extruder Mill Processing Small Livestock Pellet Press Broiler Feed Making Machine

>>

Outdoor Stainless Steel Cup Mug with Foldable Self-Lock Carabiner Handle Portable Folding Handle Cup for Camping

>>

Factory aluminum radiator for Freightliner Tomas bus OE VAB1102619 1102619AS VAB1050618 VAB1040506 VAB1102906

>>

TEM82E Magnetic Flow Transmitter Pipe Flowmeter Magnetic Type Flow Meter Price

>>

Compressed Air Industrial Automatic Vacuum 10l Vertical Sausage Filling Making Machine Stuffer for Sale

>>

Corn Maize Seeder High Precision Corn Planter and Seeder

>>

Custom Vertical CNC Milling Machining Center Single Spindle GSK FANUC Mitsubishi Control System

>>

UTERS replacement Coalescing filter element Double Open End

>>

ISO 12048 box compressive strength tester