|

US$22,000.00-120,000.00

|

1 Set

(MOQ)

|

Basic Info.

Model NO.

TSE65/70/85/90/95/120/140-P

Processing Technics

Extrusion

Bulking Machine Type

Twin Screw Bulking Machine

Expanding Method

Dry Expansion

Applicable Materials Shape

Granular

Extruder Type

Twin-Screw Extruder

Core Production Technique

Co-Rotation Twin-Screw Extrusion

Main Body Material

Stainless Steel

Dryer Heating Type

Electrical, Gas-Fired, Oil-Fired, Steam

Main Food Materials

Corn Meal, Rice Powder, Wheat Flour

Speed Control Type

Controlled by Inverters

Main Production Factors

Temperature, Pressure, Feeding Speed etc.

Motors Type

3-Phase Asynchronous Motors

Transport Package

Wooden Case

Specification

Voltage: basing on user′s workshop voltage

Production Capacity

20 Sets Per Month

Packaging & Delivery

Package Size

315.00cm * 120.00cm * 250.00cm

Package Gross Weight

1500.000kg

Product Description

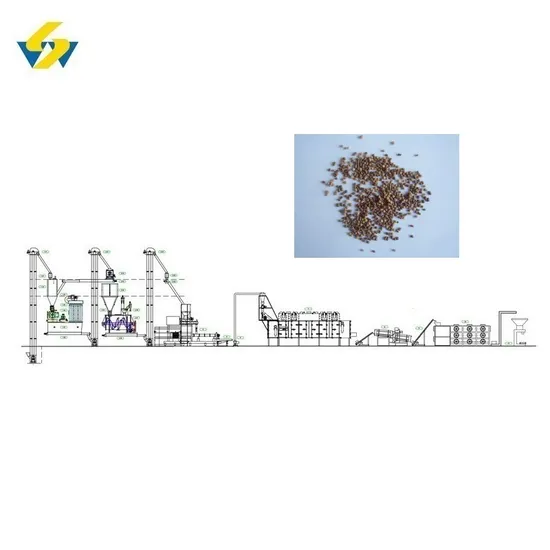

Automatic Grain-based Materials Puffed Aquatic Fish Feed Machine Animal Feed Pellet Machine Production Solution and Services Supplier

1. Expanded fish feed processing line introduction

Expanded fish feed processing line is mainly made up with raw materials treatment system, extrusion system, drying system, flavoring system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extrudate through various means to control the texture of the final product.

This line's core technology is co-rotating twin-screw extrusion. Twin-screw extruder is the core of this line, enabling the continuous production of expanded fish feed.

2. Processing line description

2.1 Flow chart: raw materials→ extrusion→ drying→ flavoring→ cooling→ packing

2.2 Processing line features

2.2.1 High work efficiency, automation degree, materials usage, application range.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 This processing line can make both floating and sinking fish feed. It can make pet food as well.

2.2.5 Production factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 All machines and fittings can be custom-made. ODM/OEM is available.

2.2.8 Professional pre-sale, sale and after-sale service.

2.3 Processing line parameters

| Type | Model | Capacity (kg/h) | Installed Power (kw) | Actual Power (kw) |

Dry

Type | TSE65-P | 100-150 | 74 | 52 |

| TSE70-P | 200-250 | 105 | 75 |

| TSE85-P | 300-500 | 205 | 150 |

Wet

Type | TSE90-P | 800-1000 | 132 | 80 |

| TSE95-P | 1000-1500 | 165 | 106 |

| TSE120-P | 2000-2500 | 226 | 140 |

2.4 Processing line machines pictures

2.4.1 Series extruders

2.4.2 Series dryers

3. Expanded fish feed samples introduction

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed. Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, expanded fish feed is made for both carnivorous and graminivorous fishes. Compared with traditional fish feed, expanded fish feed has the advantages: (1) easier feeding management (2) lower wastage rate (3) lower water contamination (4) higher feed nutritional ingredient use ratio (5) longer storage time. Expanded fish feed improves digestibility and refined the balance of nutrients to match the needs of the different species of fish more precisely at different periods of development. At the same time, expanded fish feed improves the sustainability of the ingredients used. Based on the advantages, expanded fish feed will replace traditional fish feed in the future.

4. Packing and delivery

4.1 Packed by plastic protective film or wooden case, which is seaworthy.

4.2 We can supply fumigation package and certificate.

5. Service

5.1 1 year warranty period.

5.2 Supply free fittings and general tool.

5.3 Engineers available to service machinery overseas.

5.4 Supply formula of raw materials.

5.5 Workshop design suggestion.

6. Company introduction

Jinan Sunward Machinery Co., Ltd. is Chinese leading expanded food machinery manufacturer in China.

We can design and manufacturer the machines to make expanded food for human and animals.

So far, we have 3 factories, which covers 5000 square meters. We have ISO9001:2008 & CE certificate, and pass SGS, BV & TüV inspections. We have exported our machines to more than 100 countries in the world and keep development.

>>

Engine Hood for Dodge Dart 2013-2016

>>

Manufacture Flip Cover Luxury Business Materials TPU+PU for Note12g96 X670 Phone Case

>>

Drawstring bag, backpack and handcarry bag , travel bag, shopping bag

>>

Cheap Price 1050 1060 1070 1100 3003 5052 Stucco Embossed Aluminum Coil for Building Material

>>

Automatic Egg Tray Making Machine Paper Pulp Molding Machine Price

>>

Kebida Plastic Knife Kbd3480 Paint Bucket Injection Molding Machine

>>

Easy Maintenance Guillotine Cutter Blade Paper Cutting Knife Hot Sale

>>

A large number of wholesale bbq disposable bamboo sticks

>>

4.8 grade hexagonal bolt directly supplied by manufacturer. material: galvanized. for construction projects. support processing and customization.

>>

Hcvac Plastic Car Parts Chrome Aluminum Vacuum Coating Machine

>>

Huahong Hpm-315 Semi-Automatic Horizontal Non-Metallic Baler Can Be Multiple Times to Add Material Compression

>>

Wholesale customized magnum popsicle ice cream eco wood sticks with hot stamping

>>

Steel company used femo ferro molybdenum

>>

Velvet Chair Modern Luxury Chair Velvet Dining Room Dining Room Chairs

>>

3BSC760019E1 SB822 AB12G 364-1115 3.7V 2.4AH ABB

>>

OEM manufacturer sheet metal fabrication aluminum computer steel case sheet metal box

>>

Ultrasonic Roll Welding Machine with Welding Roller for Cloth Sewing

>>

API Forged Carbon Steel/Stainless Steel Flanged Ends Top Entry Ball Valve for Gas Oil Pipe

>>

Klt-M3ma-Ar1335 Plcc V7.0 13MP Ar1335 Plcc Mipi-Schnittstelle Autofokus Kameramodul

>>

Kailong 40inch 13gg Acquard Flat Knitting Machine Accessories Collar Loom for Sweater (YX-618A)