|

US$9,000.00-20,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Application

Liquid, Liquid with Suspended Solids, Powder, Viscous Fluid

Application Area

Chemical, Daily Chemical, Food, Pharmaceutical

Control System

Buttons/PLC Control

Cooling Method

Water Cooling

Heating Method

Electric Heating/Steam Heating

Main Material

Stainless Steel

Mixing Capacity

100L-Above

Speed Control

Variable Speed

Temperature Control

with Cooling System/ with Heating

Product Name

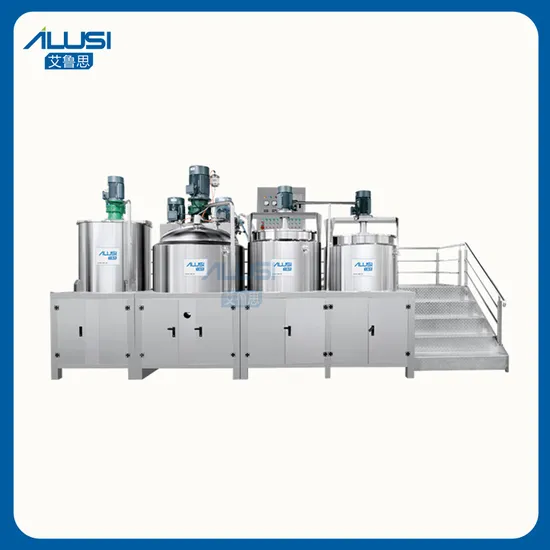

Toothpaste Vacuum Emulsifying Mixer

Material Processed

Toothpaste/Lotion/Paste/Ointment/Cosmetic

Homogenizing Speed

0-2800rpm

Applicable Industries

Hotels, Garment Shops, Building Material Shops

Function

Mixing, Homogenizing, Emulsion

Discharge

Tilting Discharge and Stator Homogenizing

Marketing Type

Ordinary Product

Transport Package

Wooden Box

Specification

2200*650*2200mm, 650kg

Production Capacity

1000 Pieces/Year

Product Description

Double Jacket Toothpaste Making Machine Cosmetics Vacuum Emulsifying Mixer Homogenizing System means when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect.

By the operation of hydraulic shearing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be dispersed and emulsified instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

The product of vacuum emulsifying mixer machine mainly applied in such industries as daily chemical care products, food industry, paint and ink ,nanometre materials, petrochemical Industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electronic and electronics, fine chemical industry, etc.

| Model | Capacity | Stirring | Homogeneous | Oil and water pot | Vacuum pump |

| KW | Speed | KW | Speed | Capacity | KW | Speed |

| AVE-200L | 60-200L | 3 | 0.62rpm | 5.5 | 0-2880rpm | 80L/180L | 0.75/0.75 | 1440rpm | 1.5 |

| AVE-250L | 60-250L | 3 | 0.62rpm | 7.5 | 0-2880rpm | 100L/225L | 1.5/1.5 | 1440rpm | 1.5 |

| AVE-300L | 90-300L | 3 | 0.62rpm | 7.5 | 0-2880rpm | 120L/270L | 1.5/1.5 | 1440rpm | 1.5 |

| AVE-350L | 100-350L | 3 | 0.62rpm | 7.5 | 0-2880rpm | 140L/315L | 1.5/1.5 | 1440rpm | 2.2 |

| AVE-500L | 150-500L | 5.5 | 0.62rpm | 11 | 0-2880rpm | 200L/450L | 2.2/2.2 | 1440rpm | 2.2 |

| AVE-1000L | 300-1000L | 7.5 | 0.62rpm | 15 | 0-2880rpm | 400L/900L | 2.2/2.2 | 1440rpm | 3 |

| AVE-2000L | 600-2000L | 11 | 0.62rpm | 18.5 | 0-2880rpm | 800L/1800L | 2.2/4 | 1440rpm | 4 |

| AVE-3000L | 800-3000L | 11 | 0.62rpm | 22 | 0-2880rpm | 1200L/2700L | 2.2/5 | 1440rpm | 5.5 |

| AVE-5000L | 1500-5000L | 22 | 0.62rpm | 30 | 0-2880rpm | 2000L/4500L | 4/7.5 | 1440rpm | 7.5 |

1. DOUBLE JACKET HEATING AND COOLING SYSTEM

The pot body adopts three layers of stainless steel imported plate welding composition, tanks and pipes for the mirror polishing, in line with GMP requirements; according to the process requirements, the tank can be heated and cooled materials, steam heating and electric heating.2. MIXING SYSTEM

One-way stirring with side scraping and bottom scraping, with dispersion function, can fully and quickly blend the materials evenly, 316 material, variable frequency speed regulation

3. HOMOGENIZING SYSTEM In the narrow gap between the stator and rotor, it is subjected to hundreds of thousands of times of hydraulic shear centrifugal extrusion, impact, tearing and other comprehensive effects per minute, instantly and uniformly dispersed and emulsified, and after high-frequency cycling, it obtains fine and stable high-quality products without air bubbles. 4. ELECTRIC BOX CONTROL SYSTEM Optional button control system/Siemens touch screen PLC system; in order to ensure the stability of the whole set of machine control, the electrical appliances are imported configuration, which can reach the international standard.5. OUTLET

Bottom top valve outlet

Top of the valve is flush with the pot

Quick discharge

No residue6. WATER AND OIL TANKS MIXING SYSTEM

With stirring and dispersing function, the material can be dissolved and pre-treated first to improve production efficiency; triple sandwich structure, optional electric heating or steam heating, in line with CMP standards.7. POWDER POT

The tank body is mirror polished and complies with GMP requirements; powder materials can be pre-processed according to process requirements. AILUSI.PROFIL

Guangzhou Ailusi Machinery Equipment Co., Ltd. was established in 2014, the factory was founded in 2007, catering primarily to industries such as cosmetics, food. With advanced technology, production and inspection equipment and the specialized processes. We have garnered praise and trust both domestically and internationally. Moving forward, we aim to uphold tradition, foster innovation, and collaborate closely with our customers for a prosperous future together.1.Why choose us?

1.1-With industry-leading technical solutions and rich experience, we are able to provide tailor-made services;

1.2-Our team has professional knowledge and innovative ability, committed to providing customers with the best solutions, can help your company quickly improve production efficiency, optimize costs, so as to stand out in the fierce competition in the market;

1.3-Our products undergo strict quality control to ensure superior quality and have good after-sales service;

1.4-We focus on customer needs, communication and collaboration to ensure the successful implementation of the project.

1.5-If you are in the start-up stage and seeking capacity expansion, we can customize a whole efficient production line service program for you, and we are committed to the design and planning to the installation and commissioning, and then subsequent after-sales service support, will be the industry's top professional standards, to ensure that your production line can run smoothly!

2.What about after-sales service?

2.1- Before leaving the factory, the factory will strictly test whether the equipment operates normally or not, and before shipping, we will operate and debug the equipment again to ensure that the appearance of each machine has no external damage and functions normally, and provide operation videos and pictures to customers to confirm that there is no error, and then packaged for shipment.

2.2-For equipment that requires on-site installation and commissioning training, we can provide professional technicians to the customer's factory for installation and training teaching services, in the process of installation and commissioning, the technicians will provide on-site guidance to help customers familiarize with the operation and maintenance of the machine.

2.3-When customers encounter problems in the process of use, we provide a variety of convenient solutions [phone, e-mail, WeChat, video instruction and other ways]

3.How do you control the quality and delivery?

3.1-If you are worried about the quality, we can sign a quality assurance certificate, which can guarantee the interests of customers and ensure that our commitment is real and effective.

3.2-We will pack each machine in export wooden case before shipment, and provide pictures before and after packing to our customers to make sure the quality is worry-free before arranging shipment.

4. What about warranty and spare parts?

4.1-We offer a standard warranty of one year from the date of purchase. Within this one year, if the product has quality problems that are not caused by human damage, we will be responsible for repairing or replacing the corresponding parts free of charge.

4.2-We ensure that we provide our customers with sufficient spare parts support. During the warranty period, if the equipment needs to be replaced due to maintenance, we will provide the necessary spare parts to ensure that the product can be quickly returned to normal use. At the same time, we also provide a spare parts purchasing service for customers who exceed the warranty period, and we undertake to provide them at cost.

4.3 - We also offer a lifetime maintenance service for our machines! Even if the machine is out of warranty, you can contact us at any time to solve any problem.

5. Are your machines difficult to operate? How do you teach us how to use the machine?

Our machines are simple to operate and easy to learn; each machine comes with a detailed instruction manual and operating video, which contains a description of the machine's functions, operating procedures, safety precautions, machine maintenance, and troubleshooting guides.

6. Can you customize the machine?

As a machine manufacturer for 20 years with a professional engineering team and advanced production facilities, we have the skilled OEM know-how to design and build machines to your specific requirements that meet your standards.

7. What about delivery time?

In stock machines: 2-7 working days; Usually 7-40 working days (depending on the product).

>>

Wheat Trasport Machinery Grain Cart

>>

Custom wholesale crew neck cotton Fleece plain round bottom side zipper Muscle fitness gym pullover hoodie for man

>>

3012002 Parker Oil Circuit Solenoid Valve RL100 Fuel Solenoid Valve

>>

Hot Sale Zinc Alloy Precast Concrete Insert/ Anchor

>>

Engine Parts Genuine Replacement Engine Timing Chain OE 0039977594 for MERCEDES-BENZ TK1040-20

>>

Wholesale Quality Model Computer Keyboard Anti-Bacterial Backlight-Rugged Industrial Medical Silicone Keyboard Onikuma

>>

Yigao Textile Small Fragrance Polyester Embroidered Fabric Lace Fabric

>>

Mini Smart TV WiFi Portable Mini Projector Game Home Cinema Theater LED USB Charging Port Pocket Projector

>>

750 Ton Automatic Plastic Injection Molding Mould Machine for Efficient Manufacturing

>>

Manufacturer Custom No Minimum Metal Military Coin Die Casting 3D Blank Army Enamel Coins Navy Air Force Brass Silver Firefighter Souvenir Challenge Coin

>>

Industrial Grade Automatic Vertical Refueling System High Quality AAC Block Machine

>>

Metal Cutting CNC Vertical Machining Center Vmc1160 CNC Milling Machine Price

>>

All Steel Radial Inner Tube Saferun Dovroad Truefast Brand 12.00r20 Truck Tyre TBR Tire (12.00r24 11.00r20 10.00r20 9.00r20)

>>

Factory Warehouse Prefabricated Steel Structure 30x40 Metal Building Welding Easy

>>

Customized Compressed Air Tank Aluminum Steel Tanks Air Tank

>>

100% High Quality PP Jumbo High UV PP FIBC Bag/ 1500kg PP Big Jumbo Bag Waste Packing Bulk Bag

>>

lint rollercar cleaning tools

>>

Best-Selling Mobile Wood Hammer Mill Crusher for Gold Mining

>>

Kitchen Appliances Home 5 In1 Multifunctional Stand Mixer with Blender and Meat Grinder Parts Food Mixers

>>

Horizontal Mixing Machine High Quality Chicken Waste Horizontal Fertilizer Mixer Machine