|

US$8,000.00-88,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

MTX300 MTX500 MTX1500 MTX2000

Material Processed

Plastic Bottle

Computerized

Computerized

Certification

ISO9001:2008, CE

Finished Product Size

16mm or Customized

Crusher Blade Material

SKD-11

Process Material

Plastic Bottles

Moisture Content Remain

Less Than 1%

Voltage

380V, 50Hz, 3phase

Final Product

Clean and Dry Flakes

Machine Material

Stainless Steel 304

Process

Crushing-Washing-Drying

Color

Grey, Green or Customized

Name

Plastic Recycling Machine Line

Transport Package

Seaworthy Packing

Specification

Dependent on models

Production Capacity

50 Sets/Year

Packaging & Delivery

Package Size

250.00cm * 180.00cm * 200.00cm

Package Gross Weight

2500.000kg

Product Description

Product Description

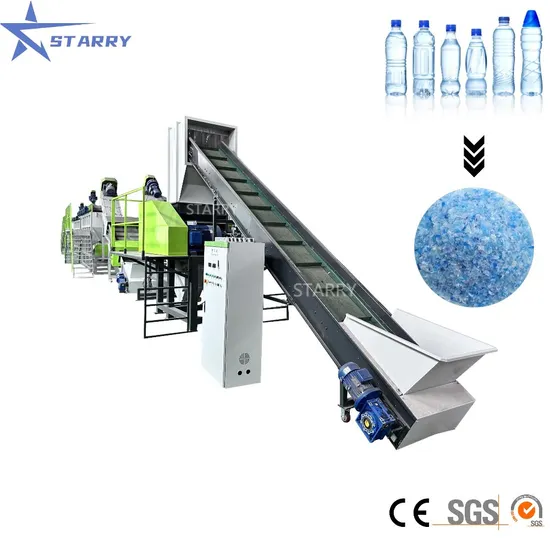

1. Application

This recycling line is composed of garbage separation (automatic & manual), bottle & flake crushing, cold & hot washing &cleaning, flake dewatering & drying, dust & label removal, packing, etc.

2. Introduction

Material: carbonated beverage bottles, drinking water bottles, fruit juice bottles, oiler, tea drink bottles, etc.

Finished product size: Less than 16mm or customized

Purpose of use: Be used for short fiber, long fiber or sheet, filament yarn, PET strap, PET sheet or PET film or bottle to bottle.

Remark: We can customize the recycling line according to client's requirement.

3. Basic Production ProcessDe-baling(bale opener)------Trommel----- Label Scrapping(label remover) ------ Manual Sorting and Metal Detecting-----Wet Grinding(crusher)-------Screw loader------Gravity Separation(floating washing tank)-------Screw loader------Chemical Washing for PET Flakes(Hot washer)-------Screw loader------High speed friction washer ------- Screw loader------Floating washing tank -------Dewatering machine--------Drying pipe system--------Label separator(Zigzag air label separator type)------Packing/storage hopper

Product Parameters

| Item | Capacity(kg/h) | Water consumption(ton/h) | Installation power(kw) | Space(m2) | Man power |

| MTX-300 | 300 | 1 | 120 | 400 | 6 |

| MTX-500 | 500 | 1.5 | 150 | 500 | 6 |

| MTX-1500 | 1500 | 3 | 340 | 800 | 10 |

| MTX-2000 | 2000 | 4.5 | 390 | 1000 | 15 |

| Equipments | Description |

| De-laber | Bottle bale opening |

| Belt conveyor | Put the material on the moving belt, which will convey the bottle into label remover |

| Trommel | Removing rock, stone, dust, loosen caps and small metals, especially, the iron will be removed by high speed |

| Bottle label separator | Removing labels from bottles |

| Manual Select working table | Manually sorting out the metal and other impurity and different color bottles |

| Crusher | Crush the material |

| Screw loader | Put the flakes into the Hot washer to clean |

| Floating washer | Cleaning flakes to remove chemicals and separating out rest labels and caps |

| Hot washer | Connected with steam boiler. Steam is supplied into washing tank to heat water and flakes. Hot water makes waste, label and glue loosen from bottles |

| Friction washer | After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect |

| Centrifugal dryer | Rejection the water from the flakes, moisture content is less than 2% |

| Pipe drying system | Hot air drying |

| PVC(label) separator | Used for the PET bottles, round and pressed bottles,effective more than 98%,save energy and labor,without water |

| Storage bunker | Storage materials |

Detailed Photos

Final Flakes

Packaging & Shipping

Company Profile

STARRY is a manufacturing company specializing in the production of plastic recycling and extrusion equipmeny, focusing on the research and development of plastic recycling and extrusion technology, providing plastic recycling, washing, regranulation, extrusion equipment and solutions. Our experienced engineers, over 25 years of knowledge and experience in plastic recycling and extrusion processing help us to contribute actively to the success of our customers by offering sustainable solutions that meet industry needs. STARRY focuses on plastic washing machines, plastic shredder, crusher, compaction and pelletizing systems, plastic extruders and control procedures that meet global standards. Our products have obtained CE/ISO/SGS/ certificate.

Certifications

FAQ

Q1. How do you guarantee the quality of your products?A1: STARRY guarantees all new products and parts to the first owner-operator to be free from defects in material and workmanship for a period of 60 months from B/L date, under normal use and service.Q2. How about the spare parts?A2: We could provide you reliable, fast and professional service through telephone, network and on-site at any time. Normally, we send our customer one set of spare parts together with the machines when we deliver the product.During the warranty, we provide new parts free of charge for you to replace, exclude the parts broken that caused by improper operation.In our spare parts department, you will get professional technical advice, as well as the relevant information regarding all products and services.Q3. About product qualityA3: STARRY is a prestigious plastic recycling and extrusion machinery manufacturer in China. Our customers have been enjoying a variety of advantages in particular in terms of the dedicated screw designed by our R&D team including good mixing, good dispersion, high productivity, and so on.Q4. After-sales serviceA4: 1.Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory.2.Offer 18 months free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost.3.Build customers database. All machines are traceable.4.Visit customers and make quality trace periodically and take customers' feedback into account during routine practices.5.Speed up service and spare parts supply.

>>

Timing Kit Chain Guide for Ford OEM 1L2Z62253BA F3AZ6L253B Timing Chain Guide Rail TR4059

>>

Cheap Price and High Quality Cdk Precision Deep Hole 12mm Hydraulic Drilling Machine

>>

thermo switch engine coolant water temperature sensor switch for Toyota 89428-15030 89428-15020 8942815030 8942815020

>>

1.8m C, Ku Band Carbon Fiber Flyaway Uplink Antenna

>>

Laser Cleaner 1000W 2000W 1500W laser Rust Removal Cleaning Machine

>>

Yada High Quality 180/200mm Resistant Reusable Bamboo Straws Drinking Wines And Drinks Wooden Bamboo Straw

>>

C6241X1000 Manual Lathe for Metal Cutting with CE

>>

3-pc 1500psi BSPT ISO 5211 DIRECT MOUNTING PAD CF8M BALL VALVE

>>

Pleated Window Screen Retractable Insect Screen Baby Plisse Plisse Screen

>>

Custom Laser Die Cut Carbon EVA Foam and EPE Foam Cardboard Tool Box Packaging Case Insert Foam

>>

Wf67K-E Automatic Aluminum Brake Press Carbon Steel Alloy Machine Tooling Metal Processing for Automation

>>

Automatic Cheese Horizontal Packing Machine Cheese Pillow Packaging Machine

>>

1000W Laser Welding Machine for Lithium Battery Modules

>>

3 Inch Lug Type Pneumatic Shafts for Slitting Machines

>>

Dragonstage Portable Soundproof Interpreter Booth Conference System Simultaneous Translation Interpretation Equipment

>>

Free Stop Damping Shaft Large Angle Torque Damping Shaft Hinge

>>

0280122014 90530439 90541502 ERR7322 TPS Throttle Position Sensor For Opel H F G Astra G Corsa B Omega B Vectra B Vauxhall

>>

90MM 36G Jigging Lure Variable Depth Artificial Fish Hunter DV5A VIB Hard Fishing Bait Lures Fishing Minnow

>>

Heavy Duty Universall Milling Machine Wn736D Swivel Head Milling Machine

>>

Automotive Lighting System Car Parts Taillight For 17-20 BMW 5 Series G30 G38 Old Upgrade New LCI 21 Style Taillight Assembly