|

US$150,000.00-200,000.00

|

1 SET/SETS

(MOQ)

|

Basic Info.

Diameter for Rebar

3-6mm/5-12mm

Max.Mesh Welding Width

3.2m

Power Supply Phases

3phase 4wire

Cooling Water Flow

150L/Min

Maximum Welding Capacity

8mm+8mm

Maximum Welding Speed

90row/Min

Transport Package

Bulk Packing and Shall Be Welded or Fastened Onto

Production Capacity

20sets/Year

Product Description

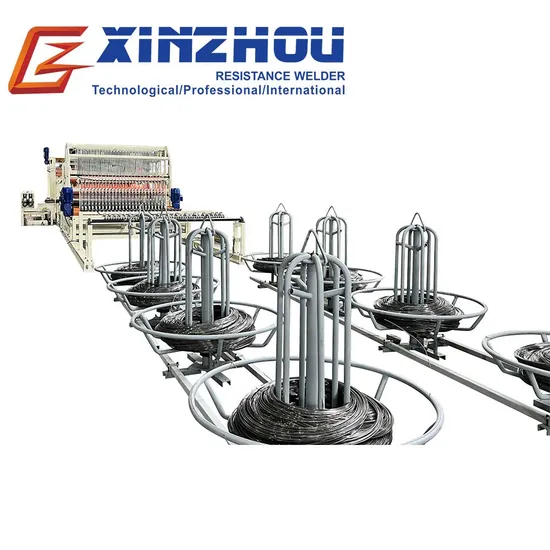

4-12mm Fully Automatic Rebar Construction Reinforcing Steel Wire Mesh Panel Welding Machine Product Description

1,GWC-A-1200 Automatic BRC Mesh Welding Line

Line wire(Φ,mm)

| 3-6

|

Cross wire(Φ,mm)

| 3-6

|

Line Wire Spacing

| ≥75mm(stepless adjustment)

|

Cross Wire Spacing

| ≥25mm(stepless adjustment)

|

Line wire feeding

| pre-cut bar

|

Cross wire feeding

| pre-cut bar

|

Max. welding speed(cross wire no./min)

| 80(spacing 50mm)

|

Rated welding transformer power

| 4x150kVA

|

| | |

2,GWC-BT-3400 Automatic Reinforcing Mesh Welding Line

Line wire(Φ,mm)

| 5-12

|

Cross wire(Φ,mm)

| 5-12

|

Line Wire Spacing(mm)

| ≥75(stepless adjustment)

|

Cross Wire Spacing(mm)

| ≥50(stepless adjustment)

|

Line wire feeding

| pre-cut bar

|

Cross wire feeding

| pre-cut bar

|

Max. welding speed(cross wire no./min)

| 80(spacing 50mm)

|

Rated welding transformer power

| 32x100kVA

|

3,GWC-B Automatic Reinforcing Mesh Welding Line

Line wire(Φ,mm)

| 5-12

|

Cross wire(Φ,mm)

| 5-12

|

Line Wire Spacing(mm)

| ≥50(increments by 50)

|

Cross Wire Spacing(mm)

| ≥50(stepless adjustment)

|

Line wire feeding

| pre-cut bar

|

Cross wire feeding

| pre-cut bar

|

Max. welding speed(cross wire no./min)

| 80(spacing 50mm)

|

|

4,GWC-BW Automatic Composite Slab Reinforcing Mesh Welding Line

Line wire(Φ,mm)

| 5-12

|

Cross wire(Φ,mm)

| 5-12

|

Line Wire Spacing(mm)

| ≥50(increments by 50)

|

Cross Wire Spacing(mm)

| ≥50(stepless adjustment)

|

Line wire feeding

| pre-cut bar

|

Cross wire feeding

| pre-cut bar

|

Max. welding speed(cross wire no./min)

| 90(spacing 50mm)

|

Bending angle(°)

| 0-145(adjustable)

|

5,GWC-C-2000 Fully Automatic Anti-crack Mesh Welding Line

Line wire(Φ,mm)

| 3.5-7.5

|

Cross wire(Φ,mm)

| 3.5-7.5

|

Line Wire Spacing(mm)

| ≥100(stepless adjustment)

|

Cross Wire Spacing(mm)

| ≥30(stepless adjustment)

|

Line wire feeding

| Coil

|

Cross wire feeding

| pre-cut bar

|

Max. welding speed

| 7 pcs /min (2000mm*3000mm)

|

Rated welding transformer power

| 5x150kVA

|

6,GWC-D Fully-automatic Reinforcing Mesh Welding Line

Ningbo Xinzhou Welding Equipment Co., Ltd. was founded in 1998, is a company mainly engaged in researching, designing, manufacturing and selling automation welding equipment, which is also a national high-new tech enterprises in China.

Its products are widely used in home appliances,hardware, auto parts production, petrochemical, liquid packaging, nuclear power station,hydropower station, steel structure platform, expressway, high-speed railway, rail transit and other large-scale infrastructure construction and precast constructions. With excellent quality and perfect service, the company has been widely recognized and unanimously praised by customers, products sell well in more than 30 countries and regions, and cooperate with a number of well-known enterprises to establish a long-term strategic partnership.

We have passed the international certifications such as CE certification, ISO9001 quality management system certification. Buyer's praise

Since its establishment 25 years ago, xinzhou has traveled to all corners of the world, participated in more than 100 exhibitions and served more than 9,000 customers

Packaging & Shipping

FAQ

Q1: What is the price of your machine?Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us thefollowing information.* The material and thickness of your product* The minimum and maximum size of your product* The welding position of your products* The automation level that you want to achieve* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.Q2: What is the warranty period of your machine?Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost. Q3: What if my machine damaged doing the warranty period?Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.Q4: What is the delivery time of your machine?Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.Q5: Can we send the sample to you for welding test?Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitableTechnical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.Q7: What's your payment terms?Answer: we can accept the following payment terms: T/T, L/C, Western UnionQ8: How can we install the machine?Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provideyou the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we willsend engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

>>

Air chute XZ500 chute pneumatic arc valve

>>

Wheat Trasport Machinery Grain Cart

>>

Custom wholesale crew neck cotton Fleece plain round bottom side zipper Muscle fitness gym pullover hoodie for man

>>

3012002 Parker Oil Circuit Solenoid Valve RL100 Fuel Solenoid Valve

>>

Hot Sale Zinc Alloy Precast Concrete Insert/ Anchor

>>

Engine Parts Genuine Replacement Engine Timing Chain OE 0039977594 for MERCEDES-BENZ TK1040-20

>>

Wholesale Quality Model Computer Keyboard Anti-Bacterial Backlight-Rugged Industrial Medical Silicone Keyboard Onikuma

>>

Yigao Textile Small Fragrance Polyester Embroidered Fabric Lace Fabric

>>

Mini Smart TV WiFi Portable Mini Projector Game Home Cinema Theater LED USB Charging Port Pocket Projector

>>

750 Ton Automatic Plastic Injection Molding Mould Machine for Efficient Manufacturing

>>

China factory Plugins LC25DB20E-7x for power station

>>

20A PVC Flag Colorful 30m Decorative Calico Flag Bunting

>>

Best Sale 26-78X100 ED Waterproof Long Range Telescope and Spotting Scope for Sightseeing

>>

Goldmore2 2000mAh USB C Tent Lamp White Warm Light Camping Lantern

>>

Domestic Vehicle Front Wheel Bearing for 2ND Gen Cars/24566101/China/Chinese Car/Auto Hub Bearing/Baojun Car/Wuling Car

>>

Dmr1000d Walk Behind Concrete Finishing Machine Power Trowel

>>

PerKins Diesel Engine Parts oil cooler(OE 2486A215/5P) for truck cooling system

>>

Double pole clothes hanger movable clothes hanger simple clothes hanger telescopic floor drying rack

>>

China High Quality Fine Acicular Wollastonite Powder Fiber for Ceramic/ Paint/ Paper Making/ Chemical/ Rubber/ Building Materials

>>

Hot Popular Fabric Karl Mayer High Speed Ks Warp Knitting Machine Guide Needle