|

US$1,599.00-2,599.00

|

1 Piece

(MOQ)

|

Basic Info.

Certification

GS, RoHS, CE, ISO9001

Automatic Grade

Automatic

Application Place

Factory

Applicable Thickness

Thick Material

Needle Number

9/12 Needles

Embroidery Type

Towel Embroidery, Patch Embroidery, Clothing Embroidery, Hat Embroidery, Flat Embroidery

Function

Shirt/Flat/3D/Sequin/Cording/Beading/Chenille/Bori

After-Sales Service Provided

Free Spare Parts, Online Support, Video Technical

Embroidery Area

350*230mm

Single Gross Weight

170.0 Kg

Hook

Japanese Hirose Rotary Hook

Power

100V/60Hz or 240V/50Hz

Memory Stitch

2000000 Stitches

Applicable Industries

Hotels, Garment Shops, Manufacturing Plant

Transport Package

Wooden Box

Specification

91X74X93 cm

Production Capacity

100000PCS/Year

Product Description

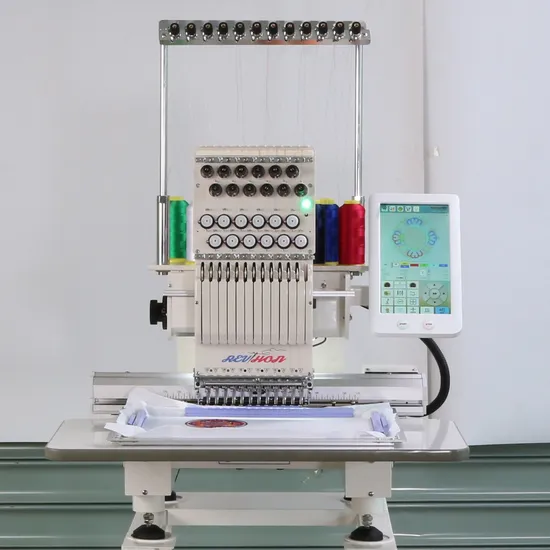

Single head home embroidery machine.

| Product Name | mini single head embroidery machine | Net Weight | 150kgs |

| Color | White | Gross Weight | 170kgs |

| Model Number | QH-MINI01 | Memory Stitch | 2000000 stitches |

| Head Number | 1 head | Cap frame unit | 270 Degree |

| Needle Number | 9/12needles | Power | 100V/60HZ OR 240V/50HZ |

| Embroidery Area | 350*230MM | Warranty | 12 Months |

*PRODUCTS DETAILS

*About us QHM

1.Company name: Zhuji Qihong Electro-Mechanical Co., Ltd. 2.Company address: No. 649, Ruancun Natural Village, Shengzhaowu 1st Village, Huandong Subdistrict, Zhuji, Zhejiang, China 3.Nearest airport: Hangzhou xiaoshan international airport 4.Nearest railway station: Shaoxing east station 5. Business Type: Manufacturer/Factory, Trading Company

Zhuji Qihong Electro-Mechanical Co., Ltd. specializes in producing computerized embroidery machines. With an advantageous geographical position and convenient transportation, our company is situated in Zhuji City - the hometown of ancient beauty - Xishi. Our company has abundant and strong technical force and complete equipment. Our major products are QHM BRAND cap computerized embroidery machines, which are regarded as High Technology Products reaching International Standard in 2000. We have passed ISO9001:2000 international quality system certification. Our company sticks to the operation idea of attaching the greatest importance to quality and customers and trying to make customers free from all worries with a perfect after-sales service system. Our company also produces computerized embroidery machines of different types to meet customers' demands. Our products are of high quality and high efficiency. Our machines can accomplish various complicated tasks, making ideal embroidery processing equipment completely and automatically controlled by computers. This kind of machine is widely used in embroidery, sick-reeling, fashion design, textiles, leather, and shoes and hat production industries. QHM Computerized Embroidery offers you our sincerity by means of high quality and perfect after-sales service. QHM will accompany your great success forever! We warmly welcome the visit and negotiation of friends from all over the world.

*Logistics packaging

*FAQ Q1:How many days about delivery time? 15-20 days after TT deposit Q2.What is the packing? General machines are with vacuum packing. Particular machine are packing with vacuum and wooden case. Container loads as per the machine size. Q3.Can you provide OEM service? we can provide OEM service. It will depend on your requests; your logo will be customized on our products. Q5: What information may contain in my inquiry? Your request your machine's embroidery area /needle number /head number/head interval/other function need.Q6. Do you test all your goods before delivery? Yes, we have 100% test before delivery Q7: How do you make our business long-term and good relationship? 1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

*Daily maintenance methods are as follows:

(1) use a brush to clean the rotating shuttle, shuttle shell and shuttle core of the hooking mechanism. Do not use sharp and hard tools to remove sundries and threads.

(2) remove sundries and thread ends at the height of wire rod, wire channel and felt;

(3) four pairs of guide rail (type 615) in front and rear of Y-axis feeding mechanism are on the same plane;

(4) two X-axis feeding mechanism guide rails are on the same plane;

(5) wire clip mechanism, wire clip, rotating wheel, wire pick, spring and wire channel are often cleaned up;

(6) cleaning sundries on the surface of work surface;

(7) the surface of the computer and the exhaust fan are often rubbed and the back cover is opened;

(8) power box, drive box surface and ventilation are often as above.

>>

Universal Modified CNC Brake Caliper Purple High Quality Motorcycle Accessories Aluminium Modified Parts

>>

Fire Hose and Horn for CO2 Fire Extinquisher Fire Fighting Equipment & Accessories

>>

China UHMWPE Bunker Coal Bin Liner for Truck

>>

Ocbs-Z1 5.99 Inch Handheld Rugged Inventory Touch Screen Android Scanner PDA

>>

7 Axis Dual Spindles CNC Lathe Machine

>>

Components Sourcing, SMT and PCB Assembly OEM Contract Manufacturing

>>

China Suppliers Grip Tape Waterproof Anti Slip Safety Tape with Yellow Waterproof Safety Grit Anti Slip Tape Custom Packing Adhesive Masking BOPP Ashesive Tape

>>

OEM 300m inflat air pillow bag bubble roll bubble package wrap packing materials air cushion bubble film

>>

Engineering Plastic UHMWPE Chute, Bin, Truck Liner

>>

SINOBI Genuine Leather men digital Watches S9797G Gentleman Watches Small Three Pins Handwatch Hand Clock Boys Relogio Masculino

>>

Custom Die Cast Aluminum Radiator

>>

Portable Aluminum Trade Show Exhibition Booth 25FT Expo Display Design

>>

QS Wholesale Alloy Pull Back 1/58 Truck Trailers Metal Kids Toy Set Oil Tank Tractor Car Diecast Trucks Vehicle Car Toys

>>

wheat cutting machines wheat cutter and binder reaper

>>

Sesame Seed Cleaning Sorting and Grading Machine Export Sanli

>>

Peanut Harvest Tools Earthnut Picker

>>

KLQ6138DF replacement higer bus spare parts 29E04-06031 front stabilizer bar bushing best price higer bus parts

>>

Kessler Disc Friction 507275913 507275923 507275.343 507275.773 Kalmar Disc 922745.0001 922746.0001

>>

High Rigidity Automatic Lathe CNC Lathe Machine Tool Turning Machine Tck63-1000

>>

Belt Buckle Cork Sandals Summer Ladies Platform Casual Open Toe Beach Slippers