Product Description

Product Description

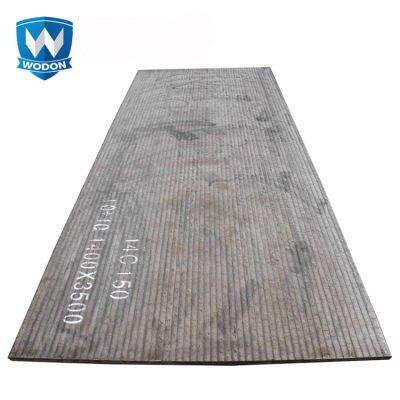

Chromium carbide overlay mild steel high wear resistant high chromium steel plateProduct DescriptionWodon high chromium carbide hardfacing wear resistant overlay plate CCO abrasion resistant high hardness anti friction overlay steel plate 10 on 10 2100*3500mm Super hardened 7 on 8 2100*3500mm submerged arc welding wear resistance plate We can customize the plates in different sizes and thickness based on customer's drawings.We can also cutting, bending and welding the wear plate into specific shapes and parts, as well as keep the good flatness. 1. Drilling Holes Staright holes and Countersunk holes.2. Bolt embedded welding in the back Embedding the pre-processed bolt in the back of wear plate.3. Bending Wodon wear plate can be cold formed and made into curve of cone.4. Welding Wodon wear plate can be welded and assembled into kinds of wear parts. Wear Plate IntroductionSix Classifications of Wodon Wear PlateNo.GradeFeature and Property1General Wear Plate C:3.0-4.5% Cr:15-27%2High Chromium Wear Plate C:3.5-5.5% Cr:27-40% , wear resistant overlay thickness maximum up to 25mm.3Impact Resistant Wear Plate Independent R&D, with high wear and high impact resistance.4Heat Resistant Wear Plate Independent R&D , with heat resistance maximum up to 900 ℃.5No Crack Wear Plate Rockwell Hardness:50-55HRC, mainly used in housing liner of steel mill, domestic unique product. 6Special Chemical Elements Wear Plate OEM customized, Chemical elements: Mo, Nb, Ni, W, V, etc.Other Feature and Property Chemical composition: Wodon wear plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. Microstructure: The carbide (Cr7C3) volum fraction on the microstructure is above 50%. Rockwell Hardness: Chromium carbide hard particles are distributed evenly throughout the layer, creating a strong microstructure, The hardness is between HRC58-65 and depend on the overlay's thickness. Wear resistance: Our test shows that the wear resistance of Wodon plate is 20 times higher than low carbon steel and 8 times than heat treated steel. Flatness tolerance: Flatness tolerance is ±3mm/m Thickness tolerance: Uniform overlay thickness, with tolerance within 0-0.5mm. The Main Thickness 3+3,4+4,5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12,12+18,12+20 14+6,14+8,14+10 16+6,16+8,16+10 18+6,18+8,18+10 20+5,20+6,20+8,20+10,30+10,40+10,20+20,20+25 We can customize the plates in different sizes and thicknesses based on customer's drawings. CertificationsAs a ISO9001 certified factory, WODON specialize in R&D and manufacturing very good quality. Hardfacing wires, hardfacing wear plates and pipes, gas shielded welding wires and kinds of wear parts, and have mort than 10 years experience in this field. In the United States, we have specialized laboratories to do wear tests. And in China, we have the inspection report issued by quality inspection center of Harbin welding institute of China academy of machinery science and technology. Test team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In our laboratory, there are have a series of equipment to test our products. Such as, Portable Spectrum can test easily the chemical compositon of wear plate surface. And we have a Spectro MAXX to read the chemical compositon directly from the powder. We use Rockwell hardness tester to test small sample from our wear plate. The test result are very accurate. We also use Portable ultronic hardness and thickness testers to test easily the hardness an thickness of wear parts on the scene. As well as we have a series of metallography experiment instruments, so the metallurgical microstructure can be analysed. The chromium carbide volume fraction on the microstructure is above 50%. The cracks on the surface of CCO wear resistant overlay plate The production process of wear-resistant composite plate is metallurgical surfacing process. The hardfacing layer is combined with steel plate, and the interface of composite material is metallurgical bonded. It has good technological performance. The base plate for the low carbon steel, the main component of the abrasion resistant layer is high carbon high chromium . The temperature difference between the steel plates near the weld bead is large, will produce uneven expansion, shrinkage and deformation. The wear-resistant layer is of high hardness and poor toughness, and the thermal expansion coefficient of the steel plate is very different from that of the wear resistant layer. The steel plate with good toughness can bear greater thermal deformation, surfacing layer with poor toughness has poor thermal deformation ability. And the thermal stress is formed inside. Therefore, a transverse crack with different sizes will be formed during the welding cooling process, which is the result of stress release. If the welding stress is not released, it is easy to crack and fall off in the later processing.Our company's wear-resistant plate through the naked eye and metallographic observation, cracks only exist in the surfacing layer. There is no crack at the base plate and the fusion line.Packaging & Shipping Wear Plate and Wear Components Packing Size wear plate size: 1400*3000mm;1400*3500mm; 14000*3400mm; 2100*3500mm, Customized.Packing Steel pallets, Non fumigation pallets, film, Customized.Delivery Time10- 40 days. Packing: We use customized size pallet to support our products and we can also make special customized steel pallet according to the customer's drawing. So that not only support our product safely but also easy to transport with. About shipping, customer can use their own designated shipping agencies, or we choose to cooperate with shipping companies. And we would make sure the delivery time is on time. Tranding methods include FOB, CIF, CFR, Letter of credit. About delivery port, because our factory is in Jiangsu, so the first choice is Jiangsu port. But if the customer has other ports want to ship, we can do the best to match customer's demond. Except for Jiangsu port, we could shipped from Lianyungang port, Shanghai port, Dalian port, Ningbo port, Shenzhen port, Qingdao port and so on. Company Information Wodon global custom designs wear resistant plate for optimum performace, fit and service life. Wodon can utilize many abrasion resistant materials, from our bi-metal alloy composite wear plate, and chromium carbide overlay wear plate, and flux cored welding wires. Wodon specializes in total wear control. We rebuild worn-out components with high wear material that will outlast new OEM components at a fraction of the cast. As a ISO9001 certified factory, WODON specialize in R&D and manufacturing very good quality hardfacing wires, hardfacing wear plates and pipes, gas shielded welding wires and kinds of wear parts, and have more than 10 years experience in this field. Wodon is committed to providing high-quality wear plate, and with good reputation. Many overseas customers willing to work with our company to establish long-term working relationship. Wodon is the leading manufacturer of wear resistant materials in China. In China, many steelworks, cement plants, coal mine plants and so on, buying wear resistant plate, wear resistant flux cored welding wires and wear resistant part from our company. As well as established a stable relationship of long-term cooperation. Abroad, our products also sold to many countries, "made in China" is not only excellent quality but also high cost performance. Wear Plate Processcing Workshop We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardfacing wear plate. It is equipped with four welding guns that can work simultaneously to overcome low productivity, poor flatness and overlay falling off, easily caused by single gun. This is a high automation level machine. Each welding gun can operate independently and restart exactly from the point it had stopped, Simplifying the operation process. Wear plate manufactured by this equipment have many advantages like flat surface, micro and irregular cracks, and uniform hardness being very well accepted by our customers. And the most advantage is cost saving, so our customer could get good quality and high cost performance wear resistant plate. CustomerWODON is committed to providing high-quality wear plate, and with good reputation. Many overseas customers willing to work with our company to establish long-term working relationship. WODON is the leading manufacturer of wear resistant materials in China. In China, many steelworks, cement plants, coal mine plants and so on, buying wear resistant plate, wear resistant flux cored welding wires and wear resistant parts from our company. As well as established a stable relationship of long-term cooperation. Abroad, our products also sold to many coutries, "made in China" is not only excellent quality but also high cost performance. Customer visit our factoryAttend the foreign exhibition Application AreaWodon wear plate general purpose chromium carbide overlay plate typically can delivery up to 30 times the life of low carbon steel plate. Combined with it's versatility, this is the reason why Wodon wear plate has become a great cost-reducer in the manufacturer of chromium carbide, cement, glass, port transportation, power and steel, as well as in mining, oil refining, and numerous material handling application, such as scrap and steel recycling. The steel manufacturing industry, for example, requires wear protection for hoppers, conveyor liners quickly erode without hardfacing protection. And coke injection line elbows, alloy hopper, reverse fan box, dust handling system, high blast furnance coke screens, replaceable ID fan housing liners, wood pulp transfer line, log stacker fork liners, mill feed chute liner, flat back elows. In mining, without hardfacing protection, critical components such as chute liners, front-end loader liners, and wear pads prematurely lose their usefulness due to the impact of silicious matter. Refuse processing plants use overlay products hydrapulper liners and beaters, screw conveyors, conical section wear liners, baler liners, tub liners, transfer points, fan blades and liners, and ash removal systems. OEM wear parts FAQ Q: Are you trading company or manufacturer? A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department. Q: How long is your delievery time? A: Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity. Q: Do you provied samples? is it free or extra? A: Yes, we could offer the wear plate and flux cored welding wires' samples for free charge. Q: What is your terms of payment? A: 30% T/T in advance, balance against copy of BL, L/C, Western Union.

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd.

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company's technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

View more

>>

Box Drawing Type Facial Tissue Machine

>>

China Dental Equipment 4 Hole Dental High Speed Handpiece

>>

Feed Grade Additives Vitamin D3 500000 Iu for Layer and Broiler Feed

>>

Customized Size Gym Wrist Straps Weight Lifting Wholesale gym weightlifting wrist strap

>>

20FT and 40FT Mobile Container Fuel Station Petrol Station Gas Station

>>

China Supplier Factory Price Cardboard Production Line Kraft Paper Jumbo Roll Production Line Corrugated Carton Paper Making Machine

>>

Pillow Core Filling Machine / Fiber Opening and Pillow Filling Machine / Cotton Pillow Filling Machines

>>

Frozen Mandarin Orange with High Quality

>>

2025 Design Promotional Advertising Outdoor Sport Beach Shark Moon Shape Flag Banner

>>

Automatic Medium Duty Knee Type Metal Vertical Milling Drilling Machine

>>

Insecticide water Efficient cypermethrin insecticide,Mosquito medicine,Fly medicine,Cockroach medicine

>>

Circumferential Seam Welding Machine with Automatic Tracker

>>

China Electric Drive Marine Hitachi Zx Home Sewer Line Replacement Hydraulic Excavator Nwe560V

>>

Unisex Polyester Padded Guitar Bag

>>

Ultrasonic Foundation Pile Integrity Tester ZBL-P8000 Series

>>

China Hot Selling Products 200-4800 Tex Fiberglass Direct Roving Fiberglass Yarn

>>

Best Selling PLC Control Injection Molding Machine

>>

Factory Price Barbecue Portable Stainless BBQ Expanded Metal Mesh

>>

Precision Pressure Gauge festo MAP-40-1-1/8-EN 161126

>>

2022 Satisfying Atmosphere Outdoor Retro Rechargeable Small LED Decorations Multifunctional Camping Lamp