Product Details

Product Description

Product Description

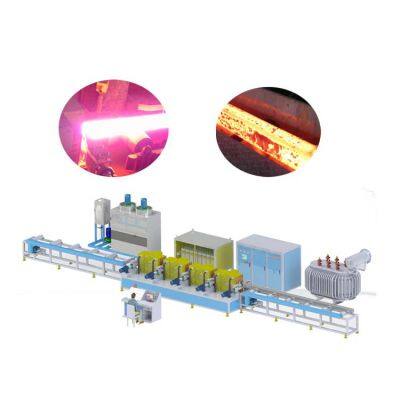

Main technical parameters of steel billet hot rolling heating furnace:

● Applicable workpieces: Suitable for pre rolling heating of steel billets, square billets, square steel, continuous casting billets, slabs, etc.

● Power supply system: Dual rectifier 12 pulse or 24 pulse 1000-12000KW/500-1200Hz, single power supply can be used independently or multiple power supplies can be used in parallel; The hourly output is 40-300 tons.

● Applicable range: 120mm~160mm square billet, length 3000mm~12000mm.

● Feeding system: Each axis is driven by an independent motor reducer, with multiple axis drives set up and controlled by a single frequency converter to synchronize the operation of multiple axes.

● Guidance system: using 304 non-magnetic stainless steel guide wheels, and maintaining moderate elasticity in the axial direction of the guide wheels to adapt to the allowable bending range of the steel billet.

● Temperature closed-loop system: A closed-loop control system composed of Leitai infrared thermometer and Siemens S7, which automatically adjusts the power supply according to the initial temperature and feed rate of the steel billet entering the sensor, so as to maintain a constant heating temperature before it is discharged from the furnace.

● Energy conversion: Depending on the surface temperature of the steel billet, the power consumption per ton of steel is 40-60 degrees

Advantages and characteristics of steel billet hot rolling heating furnace:

●If a steel billet hot rolling induction heating furnace is used in the steel billet hot processing workshop, the workshop temperature is greatly reduced due to less heat loss, which improves the working conditions in the workshop. Due to the fact that the induction heating process for hot-rolled steel billets does not produce smoke or dust during the processing of workpieces, it purifies the working environment of the workshop and meets the requirements of energy conservation and environmental protection in the new era.

●In terms of electric heating for production equipment, resistance furnaces are rarely used for heating raw materials before hot forming because the heating temperature of the raw materials is relatively high and limited by electric heating elements. Therefore, induction heating is mainly used. Induction heating of raw materials before hot forming has been used in processes such as forging, hot stamping, hot extrusion, and hot cutting of raw materials.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

>>

Residential house aluminum sunroom winter garden room design aluminum sunroom

>>

Polyester Hi vis Work Wear Long Sleeves Shirt Custom High Visibility American Workwear Shirts

>>

Powder Metallurgy Sintered Bearings for Electric Fan Motors

>>

fish feed oil sprayer, oil sprayer for fish feed

>>

New Tech PSE-Pm Series 10m Polarized Reflection Laser Photoelectric Optical Proximity Sensor NPN PNP No Nc 12V 24V with CE UL

>>

CNC Machining Aluminium Belt Pulley and Flat Belt Pulley and Timing Pulley

>>

New Design Smart Counting Hula Ring Gym Home Fitness BT Music S Hula Ring Circle with Outing Flannel White Grey/pink blue

>>

China Manual brick machine Onnoh QTJ4-40 semi-automatic brick making machine

>>

mozzarella cheese processing machine cheese cooking vat

>>

Punch Tools, Punching Tools, Punching Tooling, Thick Turret Ultra B Station Complete Set Used in Punching Machines

>>

Best Selling Soybean Cut Fuzhu Section

>>

Brightsail Three Roller Mill Coffee Nut Crusher Green Coffee Bean Grinding Machine

>>

Commercial Easy Operation Fully Automatic Meat Patty and Vegetable Patty Forming Machine

>>

Wired mouse IC Optical mouse sensor PAW3515DB

>>

China Hot Selling Pressurized Vacuum Tube 300L Solar Water Heater for Home Heating

>>

Clutch release bearing 305020F500

>>

Tp Supplemental UV IR Deep Red LED Light Bar Set for Plant LED Strip Light

>>

SC/UPC Type Optical Fiber Fast Connector

>>

FGB Spherical Plain Bearings GE70ET-2RS GE70UK-2RS GE70EC-2RS Joint bearing made in China.

>>

Factory Two Heads Multi Function 3D Monogram Flat Embroidery Machines Computerized