| Shenzhen Keyuxin Automatic Machine Co., Ltd |

| TEL:18665307510 |

| email: 570397983@qq.com |

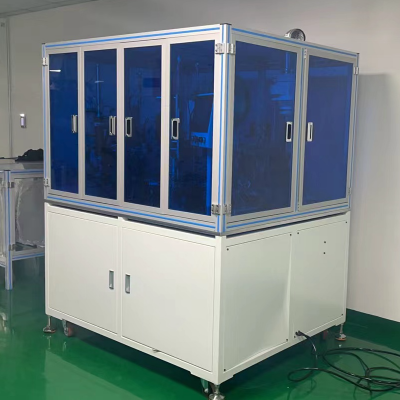

| Intelligent automatic insulation sheet assembly machine |

| Location process | The equipment can complete the assembly of rotor, AB insulation sheet, casing, commutator and bending sheet at one time, and its capacity is between 48 and 53. Can guarantee the minimum capacity of 3000 per hour. Its equipment has the function of automatic identification of ultra-short axis, the requirement is 0.3 or above. This machine is suitable for the following machine types: 300 310 500 530 130 140 180 260 N20 and all the use of insulation sheet for the insulation of the micro motor |

| Rated input voltage | AC220V /50HZ; |

| Air pressure | The working pressure is 0.5~0.7MP; |

| Air source interface dimensions | φ12 quick connector; |

| Overall size and color | 1750 x 1200 x 1800 (MM) The actual device size varies |

| The overall structure is compact, paint parts color Wanbao to green; |

| The frame part adopts aluminum profile structure specification (40 x 40) mm, transparent acrylic; |

| The production efficiency | The capacity of the equipment is 1000-1200 per hour |

| Interface | Man-machine operation interface, with the necessary protection function; |

| Unparallel ease of use | After loading the material, 1 manual guard, lack of material alarm function; |

| security | Must ensure safe operation and good grounding. |

| Ease of maintenance | UC-MAUC; |

| Basic Device Configuration | Bearing manufacturer Jingyi bearing |

| Optical fiber, sensor manufacturers Omron |

| Controller (PLC) manufacturer Xinjie |

| Operating panel (touch screen) manufacturer Xinjie |

| Motor manufacturer Oneng |

| Pneumatic components manufacturer AirTAC; |

| Buffer manufacturer AirTAC |

| Drawing list of wearing parts | PG Flash |

| Support for custom attributes. |