Product Details

Product Description

Product Description

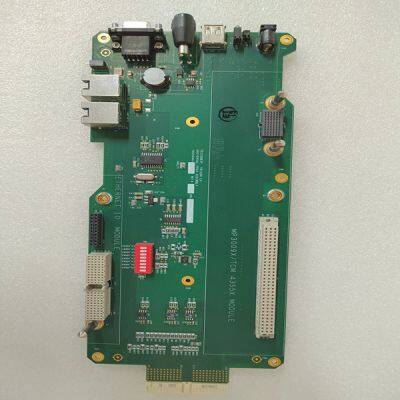

Brand:TRICONEX

Type:MP3009X TCM 4355X

Origin: the United States

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts of our products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

DETAILED DRIVE MOTOR WIRING DISCOVERY PROCEDURE Initial Set Up: Before wiring the motor, feedback device(s) to the drive turn on control power to the drive and perform a reset to factory defaults if the drive is not brand new. Then, set the feedback device parameters to match the feedback device type. Make sure to NV save these parameters. With the power off, wire the motor coils, Hall commutation signals, and encoder to the drive in any manner that seems reasonable based on the names of the terminals. For example, wire encoder A+ to drive A+, Hall 1 to drive Hall U, etc. This initial wiring is just a starting point for the process of finding a working set of wiring. Positive #1: Monitor and confirm positive encoder wiring: With the drive control power on and the drive disabled, move the motor manually in the desired direction for positive increasing motion. In S200 Tools monitor PosFB on the Status page of the tool. Be careful because PosFB wraps around every 2^16 full counts. For SynqNet units the SynqNet master’s MoCon encoder count display does not wrap around and increments in the same direction as the drive variable PosFB. If encoder counts do not increment positively, then swap encoder leads J14-13 Aux A+ and J14-14 Aux A-. NOTE: EnDat 2.1/2.2 devices are really two feedback devices in one. At power up a digital communication link gets the initial position and then the analog 1 Vp-p Sin-Cos signals are used to keep track of incremental motion after the absolute position sample. These two directions must agree. So, with EnDat devices positive motion direction is determined by the feedback device and can not be set by application requirement. To see the direction defined by the internal EnDat device power up the drive, feedback device note the position reported by the drive. Then power cycle the drive, move the position and then check the position reported by the drive. If position increased then the moved direction is positive else it was negative. Positive #2: Monitor and confirm positive Hall wiring: Assign the three Hall signals U, V, and W to traces in MoScope on the SynqNet master. For a good visual display on the MoScope software oscilloscope set the scale and offset to Ch U - Gain 6, offset -2; Ch V - Gain 6, Offset 0; Ch W - Gain 6 Offset 2. With the drive disabled manually move the motor in the positive direction. Hall signals U, V, W should form a three phase set with: V lagging U by 120 degrees and W lagging V by 120 degrees. In truth table formate, use the following for positive direction movement: In (Hall UVW format): (101), (100), (110), (010), (011), (001). If the Hall sequence is not in the expected U then V then W 120 phase order, then Hall wires will need to be swapped. NOTE: In some non-Danaher Motion systems the Halls have 60 degree separation which is equivalent to the Danaher Motion standard with the middle signal Hall V logically inverted. The S200 drive is not compatible with this non-standard Hall format. The inverted logic Hall commutation signal will have to be inverted by circuitry outside of the S200 to get the system to work.

>>

Multi Purpoae Industrial Stainless Professional Automatic Mechanical Best Thin Meat Machine Slicer Electric Heavy Duty

>>

CT2520 Lathe Machine Metal Combination Lathe

>>

All New Plastic Chair Making Machine Injection Molding Machine

>>

Module spare parts SC510 3BSE003832R1

>>

Byloo China Topwater Wobblers Minnow Crankbaits for Fly Fishing Artificial Insect Soft Lures Frog Fishing Lure

>>

Portable Hanging Household Outdoor Plastic Silicone Fishing Bucket Toy Bucket Folding Car Wash Bucket Children Toy Bucket

>>

Remote Controlled Automatic Butter Cream Horizontal Flow Packing Machine Cheese Packaging Machine

>>

Shenzhou Granulator Wooden Case 100m*24m*8m Machine Organic Fertilizer Production Line

>>

Slow Release Type Polymer Fertilizer Coating Materials

>>

Light Culture Incubator

>>

OTDR5000 Touch Screen OTDR

>>

Perforated Metal Mesh Exterior Wall Cladding Modern Building Materials

>>

Kurkure Crispy Snack Making Machine for Global Manufacturers

>>

22.3feet 6.8m Inflatable Rib Boat, Rescure Boat, Fishing Boat, Rigid Hull Boat, PVC and Hypalon

>>

Fully Automatic 20L Jerry Can Double 3 Layer Extrusion HDPE Moulding Plastic 20 Liter 25L Jerrycan Bottle Blow Molding Machine

>>

Widely Used 3015 Fiber Laser Cutting Machine 2000W Plate and Tube CNC Fiber Laser Cutting Machine

>>

Sf250 High Efficiency Popular Stainless Steel Commercial Industrial Spice Grinder Machine

>>

Patio Coverings Bioclimatic pergola Motorized Adjustable Opening Louver Roof Pergola

>>

Manufacturers Wholesale Customized Mens Sport Socks Men

>>

Customized 1.5-13mm Vertical Sumore Mini Press Equipment Bench Milling Drilling Machine Drill