|

US$20,000.00-500,000.00

|

1 Set

(MOQ)

|

Basic Info.

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Free Electron Laser

Laser Technology

Laser Control Fault Cutting

Control System

Pmac Full Closed Loop Servo Control

Laser Type

Ipg or Chuangxin or Ryko

Beam Quality

2.8-3.6mm X Mrad

Maximum Cutting Width

6000mm * 2500mm

X/Y Axis Positioning Accuracy

±0.05mm/M

X/Y Axis Repeated Positioning Accuracy

±0.03mm/M

Transport Package

Wooden Case

Production Capacity

100 Sets/ Month

Product Description

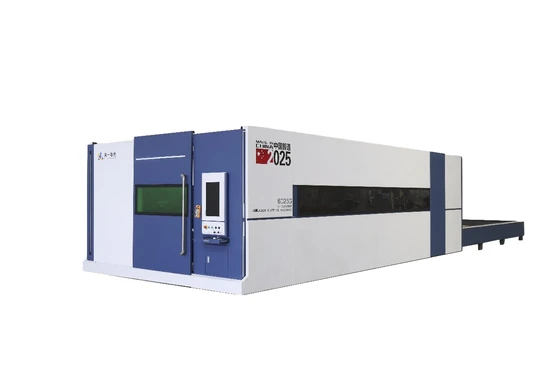

6025 High speed 1000W 1500w 3000w 4000w 6000W laser Fiber cutting machine exchange platforms for metal Product Description

Choose Chuangxin fiber laser generator

High electro-optical conversion rate

Excellent beam quality

Long service life

Low cost of comprehensive use

Maintenance free

Inovance servo motor

High stability, high precision and maintenance free.

High precision. back clearance less than 3 arc minutes, accurate positioning.

High rigidity, high torque.The use of integral roller bearings, greatly improve the rigidity and torque.

No grease leakage. The use of high viscosity, not easy to separate grease, effectively prevent grease leakage.

Easy maintenance, no need to replace the grease during the life of the product.

Pinion rack and rail Control system Work surface

| 1.5 kw | Material category | Carbon steel | Stainless steel | Aluminum alloy | Brass | Red copper |

| Cutting speed m/min | Material thickness (mm) | O2 | Nitrogen | Air Air | N2 nitrogen | Air Air | N2 nitrogen | N2 nitrogen | O2 Oxygen |

| (Oxygen focusing) |

| 1 | 6.0-8.0 | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | / |

| 2 | 5.0-6.0 | 8.0-10.0 | 8.0-10.0 | 8.0-10.0 | 8.0-10.0 | 10.0-14.0 | 10.0-12.0 | / |

| 3 | 3.8-4.2 | / | / | 5.6-6.7 | 5.6-6.7 | 6.0-8.0 | 4.0-5.0 | / |

| 4 | 3.0-3.4 | / | / | 3.8-4.0 | 3.8-4.0 | 3.0-4.0 | 2.5-3.0 | / |

| 5 | 2.9-3.3 | / | / | 2.0-2.2 | 2.0-2.2 | 2.1-2.5 | 1.5-2.0 | / |

| 6 | 2.4-2.6 | / | / | 1.2-1.4 | 1.2-1.4 | 1.7-2.0 | | / |

| 8 | 1.4-1.6 | / | / | / | / | / | / | / |

| 10 | 1.0-1.2 | / | / | / | / | / | / | / |

| 12 | 0.9-1.1 | / | / | / | / | / | / | / |

| 14 | 0.7-0.9 | / | / | / | / | / | / | / |

| 16 | 0.5-0.6 | / | / | / | / | / | / | / |

| 18 | / | / | / | / | / | / | / | / |

| 20 | / | / | / | / | / | / | / | / |

| Note: 1. The above cutting parameters are the factory test data of the equipment, for reference; (marked in red is the limit) |

| 2. Auxiliary gas is air, when cutting stainless steel, with 15KW air system. |

| 3KW | Material class | Carbon steel | Stainless steel | Aluminum alloy | Brass | Red copper |

| Cutting speed m/min | Material thickness (mm) | O2 | Nitrogen | Air Air | N2 nitrogen | Air Air | N2 nitrogen | N2 nitrogen | O2 Oxygen |

| (oxygen focus) |

| 1 | 7.0-10.0 | 30.0-40.0 | 30.0-35.0 | 30.0-35.0 | 30.0-35.0 | 30.0-35.0 | 18.0-20.0 | / |

| 2 | 5.0-6.5 | 15.0-18.0 | 15.0-18.0 | 15.0-23.0 | 15.0-23.0 | 12.0-18.0 | 9.0-12.0 | / |

| 3 | 3.5-5.0 | 6.0-9.0 | 6.0-9.0 | 7.0-11.0 | 7.0-11.0 | 6.5-10.0 | 4.0-6.0 | / |

| 4 | 3.0-4.2 | / | / | 4.0-6.5 | | 3.5-5.0 | 2.5-4.0 | / |

| 5 | 2.5-3.5 | / | / | 2.5-4.0 | | 2.5-3.5 | 1.5-2.0 | / |

| 6 | 2.4-3.0 | / | / | 2.0-3.2 | | 1.8-3.0 | 1.0-1.3 | / |

| 8 | 1.8-2.4 | / | / | 1.2-1.8 | | 0.9-1.3 | / | / |

| 10 | 1.2-1.8 | / | / | 0.5-0.8 | | 0.6-0.8 | / | / |

| 12 | 1.0-1.5 | / | / | / | | / | / | / |

| 14 | 0.8-1.0 | / | / | / | | / | / | / |

| 16 | 0.7-0.85 | / | / | / | | / | / | / |

| 18 | 0.6-0.8 | / | / | / | | / | / | / |

| 20 | 0.5-0.65 | / | / | / | | / | / | / |

| Note: 1. The above cutting parameters are the factory test data of the equipment, for reference; (marked in red is the limit) |

| 2. Auxiliary gas is air, when cutting stainless steel, with 15KW air system. |

| 4KW | Material category | Carbon steel | Stainless steel | Aluminum alloy | Brass | Red copper |

| Cutting speed m/min | Material thickness (mm) | O2 | Nitrogen | Air Air | N2 nitrogen | Air Air | N2 nitrogen | N2 nitrogen | O2 Oxygen |

| (Oxygen focusing) |

| 1 | 7.0-10.0 | 20.0-30.0 | 25.0-35.0 | 25.0-35.0 | | 25.0-35.0 | 18.0-20.0 | 18.0-20.0 |

| 2 | 5.5-6.5 | 16.0-19.0 | 16.0-19.0 | 17.0-25.0 | | 16.0-20.0 | 13.0-15.0 | 9.0-12.0 |

| 3 | 3.8-4.5 | 10.0-12.0 | 10.0-12.0 | 10.0-15.0 | | 7.0-13.0 | 6.0-6.5 | 5.0-6.0 |

| 4 | 3.3-3.8 | 4.5-7.0 | 4.5-7.0 | 5.0-7.5 | | 4.0-5.5 | 4.0-4.5 | 3.5-4.5 |

| 5 | 3.0-3.6 | / | / | 4.0-5.0 | | 3.0-4.0 | 2.5-3.0 | 1.5-2.5 |

| 6 | 2.6-2.9 | / | / | 3.0-4.0 | | 2.2-3.5 | 1.7-2.0 | / |

| 8 | 2.4-2.6 | / | / | 1.5-2.6 | | 1.0-1.6 | 0.7-0.9 | / |

| 10 | 1.8-2.1 | / | / | 0.8-1.3 | | 0.6-1.0 | / | / |

| 12 | 1.1-1.6 | / | / | 0.6-0.8 | | 0.3-0.4 | / | / |

| 14 | 0.8-1.0 | / | / | 0.2-0.3 | | 0.2-0.3 | / | / |

| 16 | 0.7-0.9 | / | / | / | | / | / | / |

| 18 | 0.6-0.8 | / | / | / | | / | / | / |

| 20 | 0.5-0.6 | / | / | / | | / | / | / |

| Note: 1. The above cutting parameters are the factory test data of the equipment, for reference; (marked in red is the limit) |

| 2. Auxiliary gas is air, when cutting stainless steel, with 15KW air system. |

| 6KW | Material category | Carbon steel | Stainless steel | Aluminum alloy | Brass | Red copper |

| Cutting speed m/min | Material thickness (mm) | O2 | Mix | Air | N2 | Air | N2 | N2 | O2 |

| (Oxygen focus) | (Mixture/nitrogen maker) |

| 1 | 7.0-10.0 | 30.0-50.0 | 30.0-50.0 | 30.0-50.0 | 30.0-50.0 | 30.0-50.0 | 30.0-50.0 | 23.0-25.0 |

| 2 | 5.0-7.0 | 25.0-30.0 | 25.0-30.0 | 20.0-30.0 | 20.0-30.0 | 20.0-30.0 | 20.0-24.0 | 12.0-15.0 |

| 3 | 4.5-6.0 | 15.0-17.0 | / | 15.0-17.0 | 15.0-18.0 | 15.0-17.0 | 12.0-15.0 | 6.0-8.0 |

| 4 | 3.5-3.9 | 10.0-12.0 | / | 10.0-12.0 | 10.0-13.0 | 10.0-12.0 | 8.0-10.0 | 4.0-5.0 |

| 5 | 3.2-3.5 | 6.5-7.3 | / | 6.5-8.0 | 6.5-9.0 | 6.5-7.3 | 5.0-6.5 | 2.5-3.0 |

| 6 | 2.9-3.2 | 4.5-6.0 | / | 4.5-6.0 | 4.5-7.0 | 4.5-6.0 | 3.0-4.5 | 2.0-2.5 |

| 8 | 2.5-2.7 | / | / | 3.0-3.5 | 3.0-4.0 | 3.0-3.5 | 1.2-1.8 | 1.0-1.5 |

| 10 | 1.9-2.2 | / | / | 2.2-2.5 | 2.2-3.0 | 2.2-2.5 | 0.9-1.2 | |

| 12 | 1.8-2.1 | / | / | 1.6-1.9 | 1.6-2.0 | 1.7-1.9 | / | / |

| 14 | 1.4-1.8 | / | / | 0.8-1.3 | 0.8-1.4 | 0.8-1.0 | / | / |

| 16 | 1.3-1.6 | / | / | 0.7-0.9 | 0.7-1.0 | 0.6-0.8 | / | / |

| 18 | 0.8-1.2 | / | / | 0.5-0.65 | / | | / | / |

| 20 | 0.6-0.8 | / | / | | / | | / | / |

| 25 | 0.2-0.3 | / | / | / | / | / | / | / |

| Note: 1. The above cutting parameters are the factory test data of the equipment, for reference; (marked in red is the limit) |

| 2. Auxiliary gas is air, when cutting stainless steel, with 15KW air system. |

Company Profile

About Us

Established in 1992, Tianyi has evolved over the past three decades to become a frontrunner in the welding and cutting industry. As a multifaceted welding conglomerate, Tianyi specializes in the development of cutting-edge welding technology, the crafting of intelligent equipment, and the advancement of superior welding products. Our extensive expertise spans the creation of internet-based welding software management systems, comprehensive training, certification consulting, and meticulous testing services. With eight subsidiary companies, three expansive manufacturing bases, and five state-of-the-art research and technology platforms, Tianyi is at the industry's forefront. We pride ourselves on our team of 300 technical experts and an impressive portfolio of over 100 patents. Generating sales exceeding 100 million dollars, Tianyi serves a vast clientele and collaborates with renowned corporations such as Panasonic (Tangshan), Fronius, and Messer, among others. Our brand enjoys a stellar reputation, both within China and internationally.

Customer List

>>

Full Automatic Cost Effective Bed Lathe Precision Engineering Metal CNC Lathe Machine

>>

Good Quality Chicken Egg Incubator Duck Egg Tray Incubator Machine

>>

530-1006001S1 camshaft for yuchai 4110

>>

FI840F ABB module inventory spot sale

>>

for Trucks Shakman FAW Jiefang Sinotruck Brake Clearance Adjuster HD90149340139 Truck Manual Clearance Adjuster

>>

Variable Speed Drilling and Milling Machine Zay7032V/1

>>

Vacuum Tube Solar Collector Project for Tobacco Leaf Drying

>>

Febi Bilstein High Quality Timing Chain Kit for Mitsubishi Engine Code 4B Outlander Lancer TK8060-3

>>

ABS Plastic Air Warm Water Hot Pump Swimming Pool Heating Pump

>>

Wholesale Factory Price Polyvinyl Chloride Compound PVC Pellets Grain Particle Recycled PVC Granulator Granules

>>

2024 China Newest Crop Fresh Bell Pepper Red Yellow Green Pepper

>>

MY style body kits for Porsche Cayenne 958 FRP+CF Material 2011-2014 Year

>>

Multi-Function Hammer

>>

China HDPE Plastic Road Barricade Table Pallets Making Machine (PXB120A)

>>

sponge drain holder Sink Caddy Sponge Holder, Hanging Dish Sponge Organizer Holder, Over Sink Expandable Brush Soap Storage Rack

>>

HD Cable, Male to Female Plug

>>

ASME B16.5 Nps10"150lb 300lb 600lb 900lb 1500lb Stainless Steel Forging Welding Neck Flange

>>

Orange Automotive Masking Tape From China Factory

>>

Tb98A-30 Drive

>>

Concrete ultrasonic detector/Ultrasonic pulse velocity tester